Correction force test system for stealth appliance

A technology of invisible appliance and testing system, applied in force/torque/work measuring instruments, instruments, measuring devices, etc., can solve the problems of small force space and high measurement accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

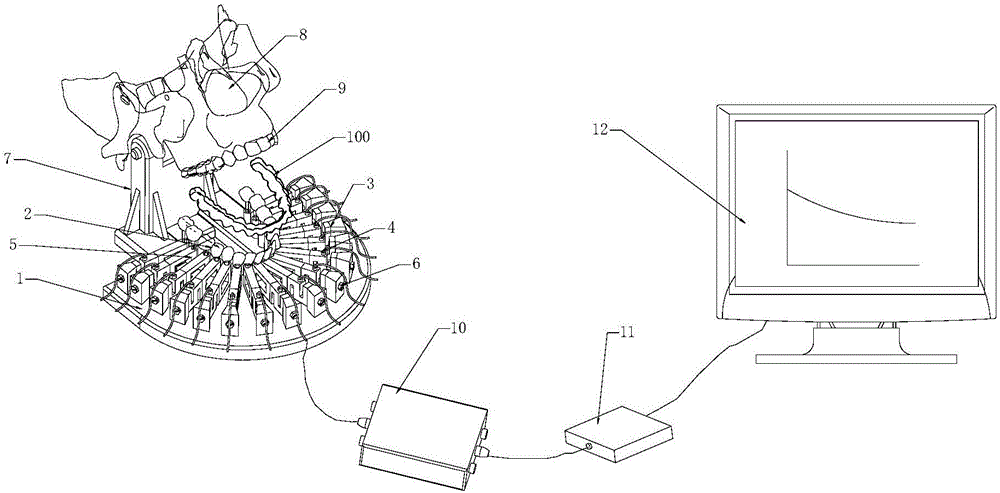

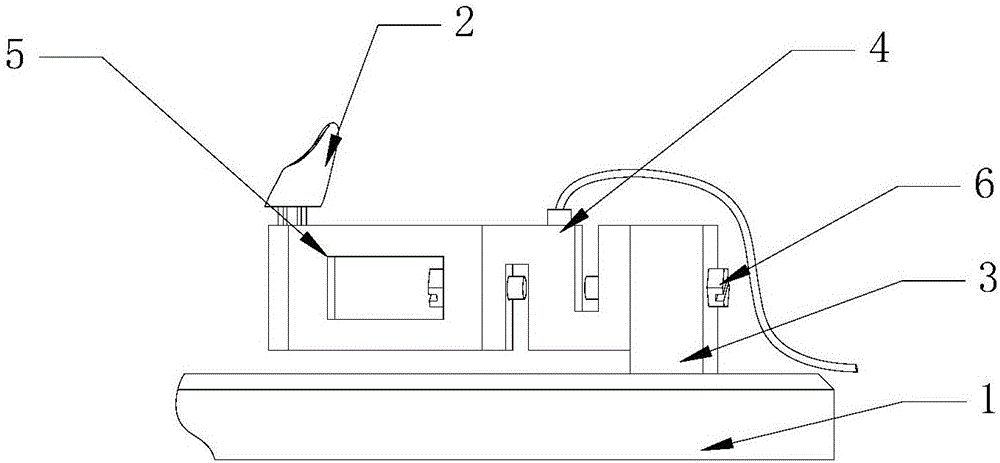

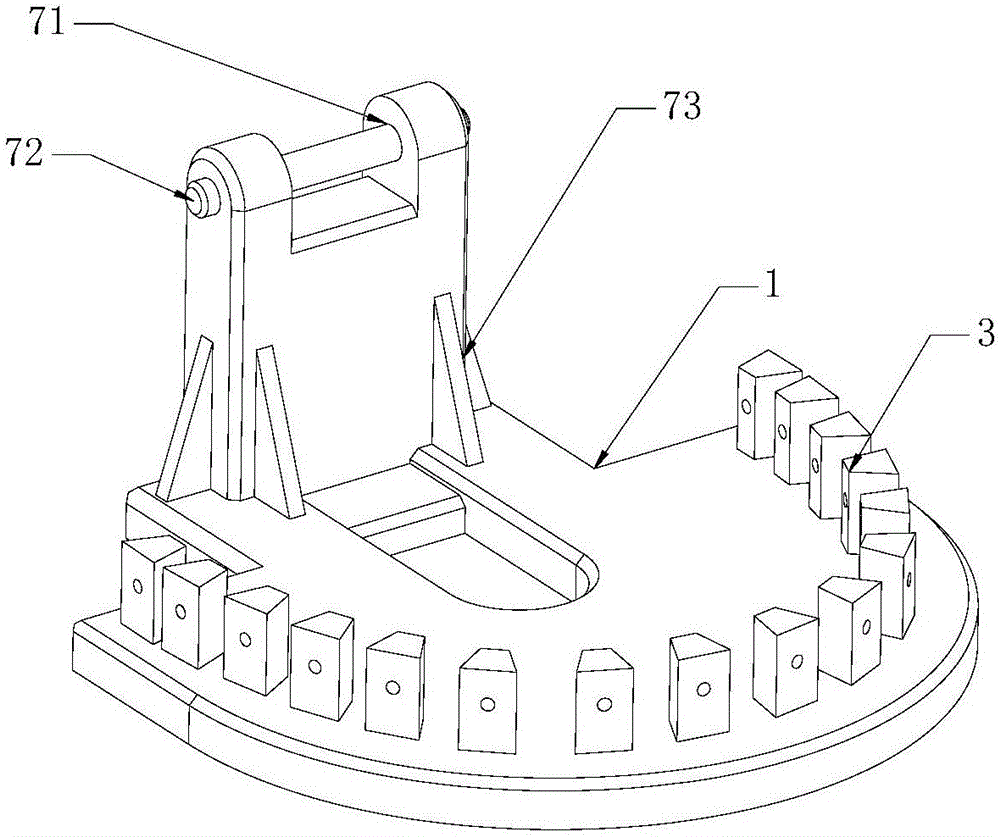

[0027] see figure 1 , figure 2 and image 3 , the orthodontic force testing system for invisible aligners of the present invention includes a base 1, a simulated mandible to be corrected and anchored teeth 2, a plurality of sensor supports 3, a plurality of multidimensional force sensors 4, a plurality of force transmission links 5, a plurality of A connecting piece 6, a pair of support rods 7, a simulated skull 8, simulated maxillary teeth 9, a multi-channel signal transmitter 10, a multi-channel signal converter 11, and a signal display and processing device 12.

[0028] The base 1 is semicircular. The simulated mandibular corrected and anchored teeth are located at the center of the base 1 .

[0029] Each sensor support 3 is fixed on the edge of the base 1 in an annular array, and corresponds to each tooth of the artificial mandibular to be corrected and supported b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com