Vibration clamp and vibration test method

A vibration test and fixture technology, which is applied in vibration test, machine/structural component test, measuring device, etc., can solve the problems of easy damage, high cost and long time consumption of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

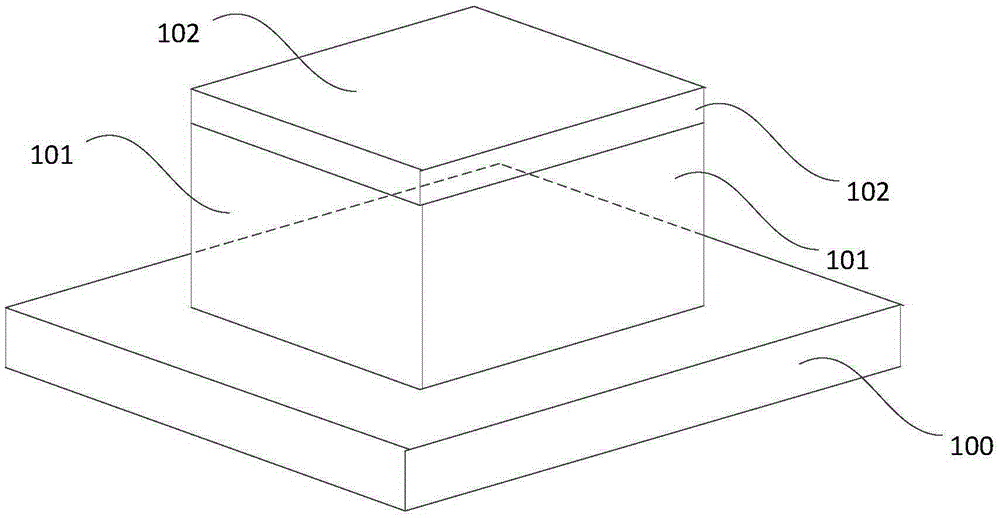

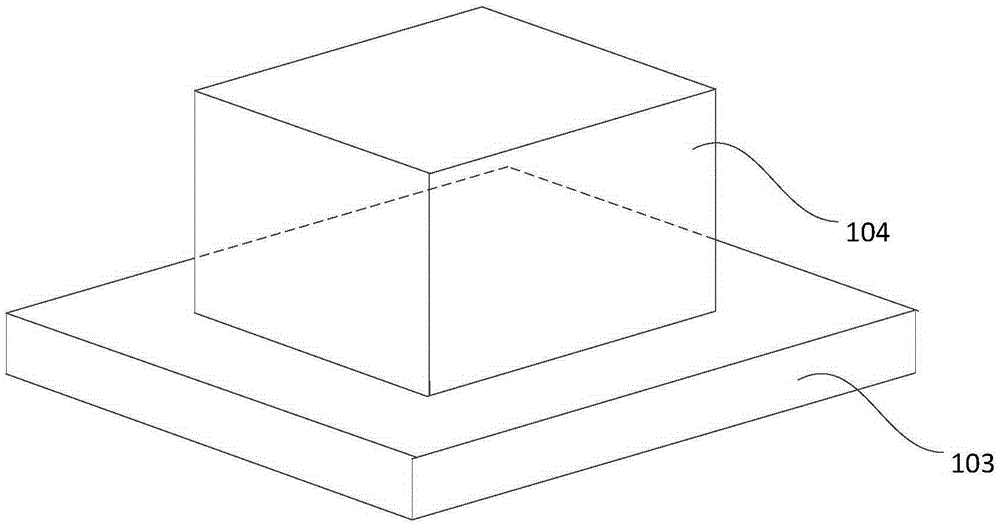

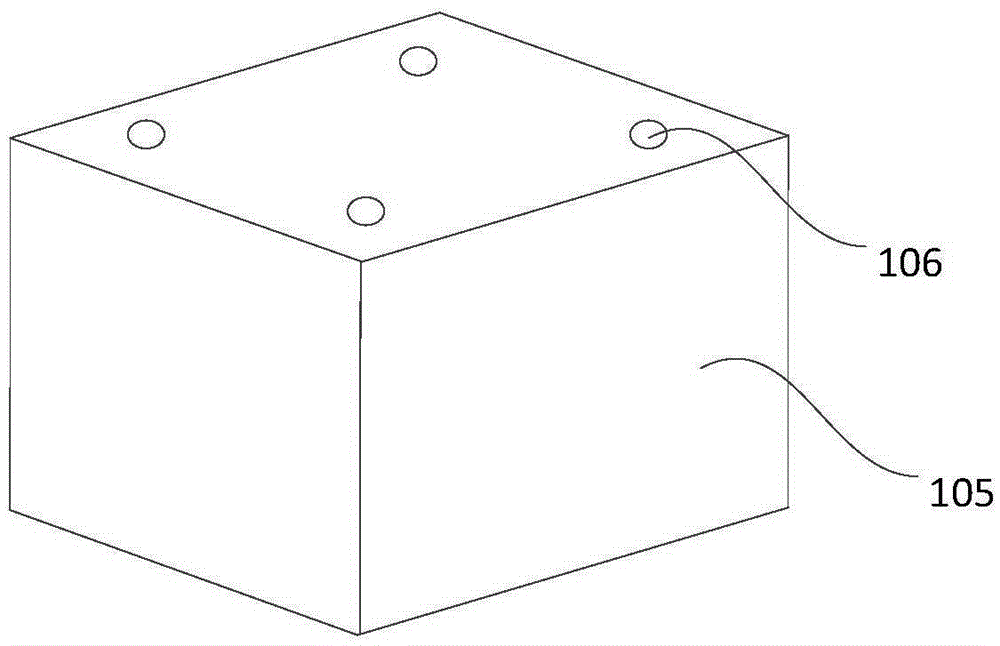

[0094] Embodiment 1 of the present invention provides a vibrating fixture, which is a combined flipping vibrating fixture, used to fix the product to be tested in the vibration test, including a fixture main body with at least one mounting surface and detachably fixed by a locking structure The connector at the mounting surface of the fixture main body, on which the product to be tested is detachably fixed, the fixture main body has three bottom surfaces, one of which is detachably fixed on the vibrating device (in In this embodiment, it is a vibrating table), the bottom surface is a plane, and the three bottom surfaces are adjacent to each other and are perpendicular to each other. The main body of the fixture also has three adjacent surfaces. At least one of the surfaces is the installation surface, and the three surfaces are respectively opposed to the three bottom surfaces, and the three surfaces are respectively arranged along three directions perpendicular to each other, ...

Embodiment 2

[0127] In the second embodiment, the product to be tested is an electronic throttle. The second embodiment is mainly different from the first embodiment at the installation station of the product.

[0128] In the first embodiment, the installation station is a plane, and there is a fourth installation hole on the plane, and the electronic throttle is fixed on the connecting piece 2 through the fourth installation hole. combine Figure 9-10 , In the second embodiment, a different installation station is provided. The installation station has an L-shaped groove in cross section, and the L-shaped groove matches the size of the electronic throttle. That is to say, Embodiment 2 provides another way of setting up the installation station. In addition, the vibrating fixture is also provided with a gantry unit for fixing the product wiring harness. For the introduction of the gantry unit, please refer to Embodiment 6 of the present invention. In addition, other technical solutions a...

Embodiment 3

[0130] In this embodiment, compared with the first embodiment, the structure of the connector 2 is changed to standardize the direction of the product wiring harness.

[0131] A plurality of the connectors 2 have the same size. In this example, if Figure 11 As shown, the connector 2 includes a first plate 8 and a second plate 9 that are detachably fixedly connected to the first groove 3, the first plate 8 and the second plate 9 are integrated, and the first The plate 8 has one side fixed in the first groove 3 and the other side fixedly connected with the second plate 9 on which the product to be tested is fixed.

[0132] In this embodiment, the first plate 8 and the second plate 9 are both rectangular plates, and the first groove 3 is a U-shaped groove, please refer to Figure 5 and Figure 11, the interior of the first groove 3 has two parallel sides, which are the first side 31 and the second side 32, and the second plate 9 has the third side 91 and the fourth side 92 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com