Multiple injection propulsion mechanism

A propulsion mechanism, a technology of a propulsion mechanism, applied in the direction of analyzing materials, instruments, etc., can solve problems such as long time-consuming, low detection efficiency, and extended detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below by means of the accompanying drawings, but the present invention is not limited only to the following embodiments.

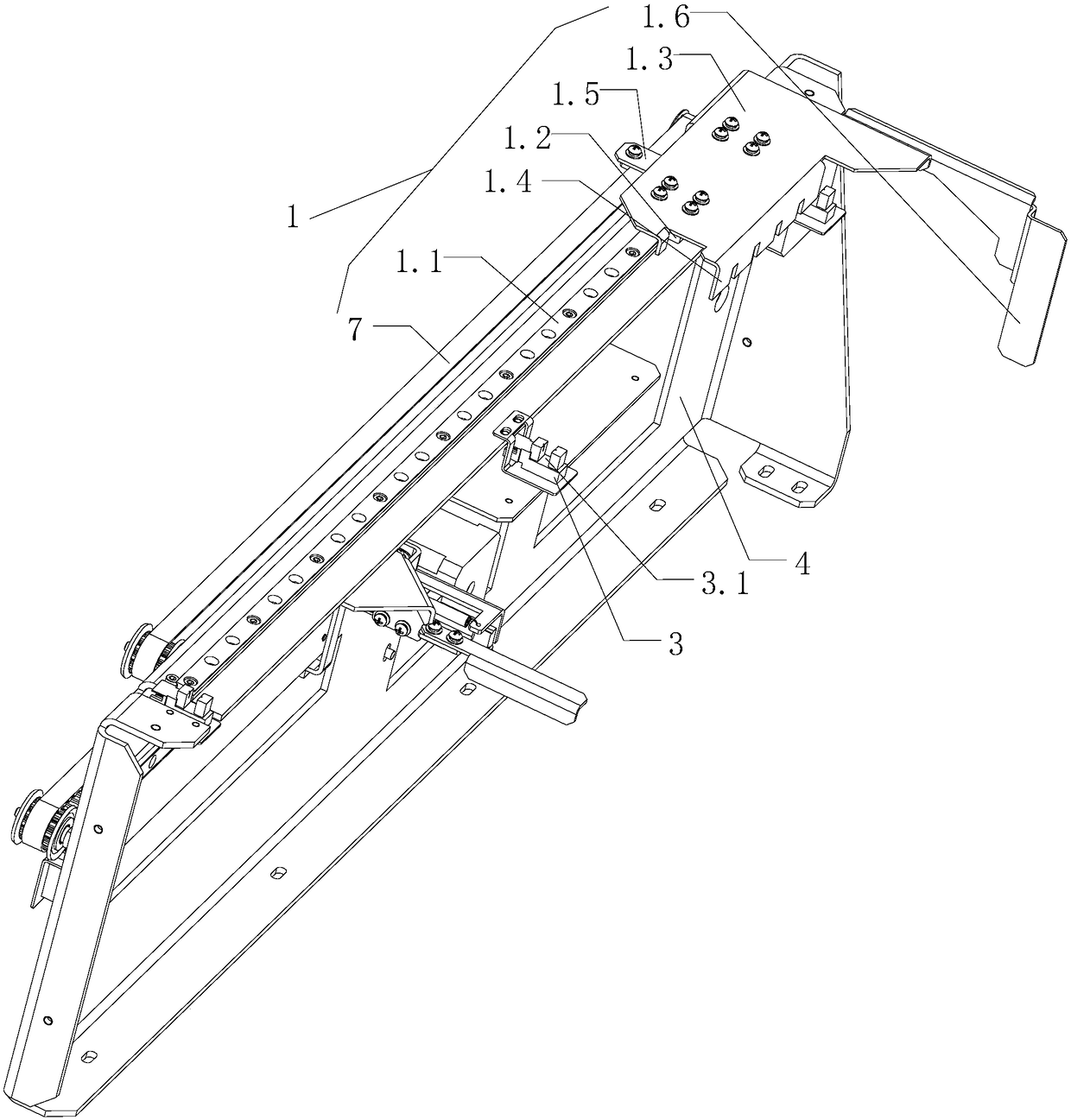

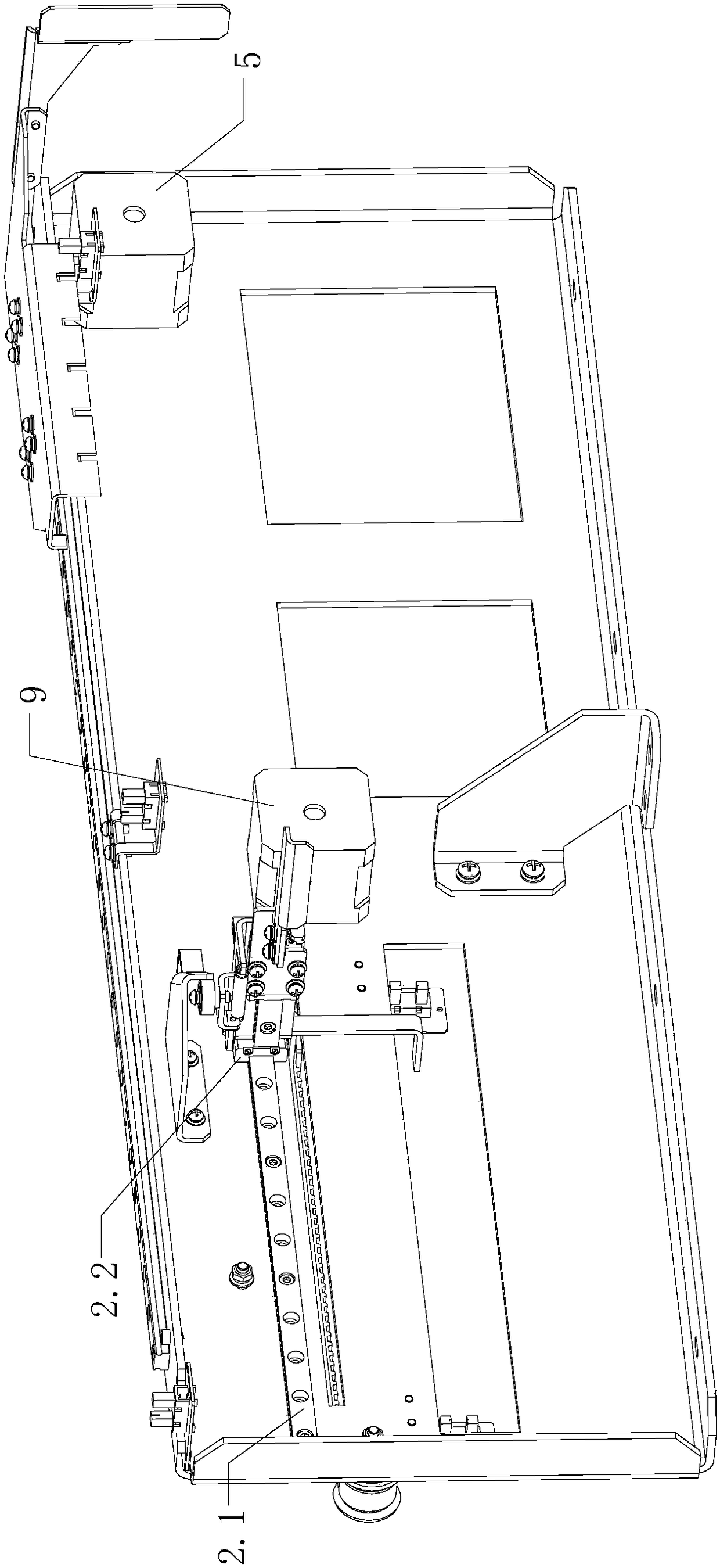

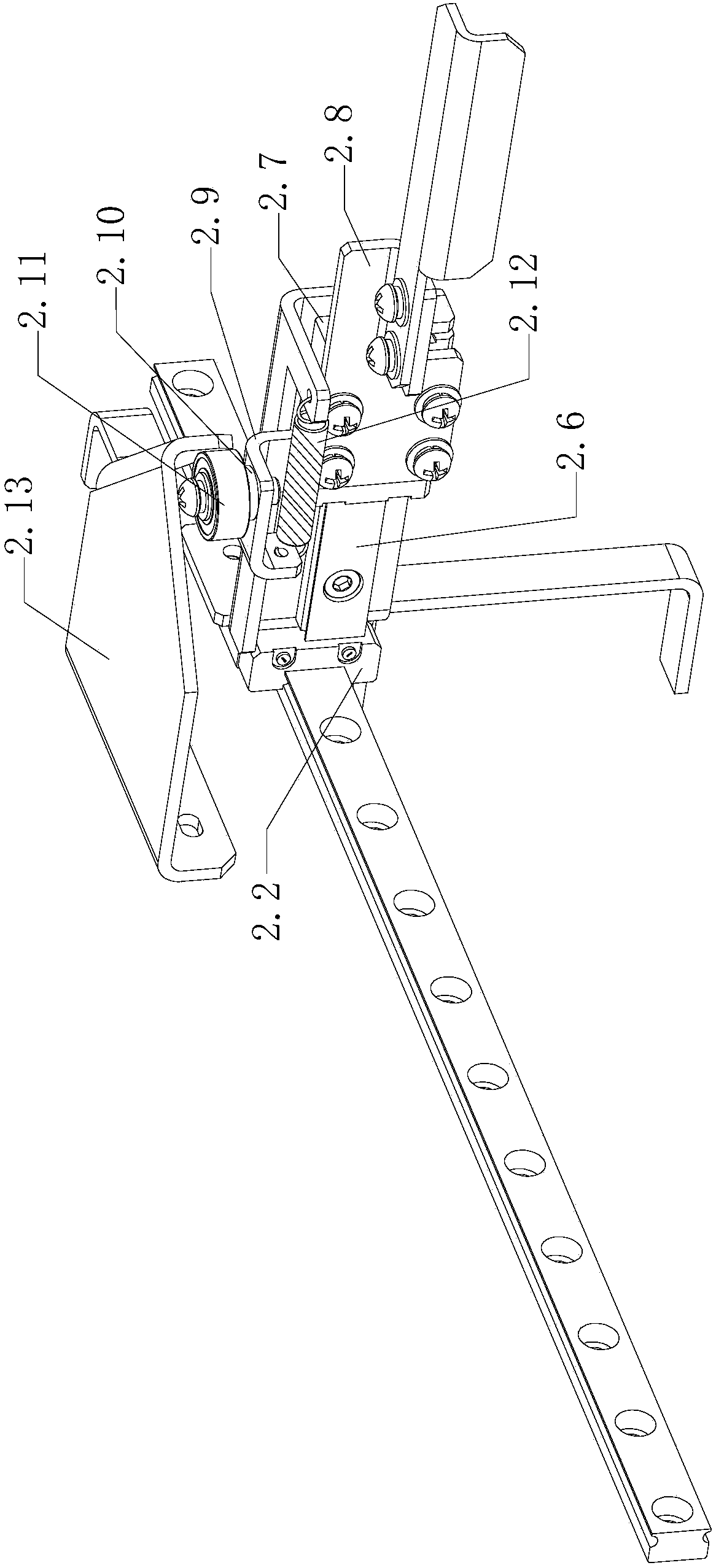

[0021] as attached Figure 1-3 As shown, a multiple sample injection propulsion mechanism of the present invention, the structure includes a sample rack first push mechanism 1, a sample rack second push mechanism 2, an optocoupler 3 and a base 4;

[0022] The first push mechanism of the sample rack includes a first guide rail 1.1 extending along the length direction of the base, a first slide block 1.2 is slidably fitted on the first guide rail, and a first shift fork is provided on the upper end surface of the first slide block Fixed plate 1.3, the front end surface of the first shift fork fixed plate is provided with a code disc 1.4, the rear end surface of the first shift fork fixed plate is provided with the first connection block 1.5 connected with the first driving device, the first shift fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com