A determinant conductance probe system and liquid film thickness measurement method suitable for annular flow liquid film thickness measurement in narrow rectangular channels

A rectangular channel, liquid film thickness technology, applied in the direction of electrical/magnetic thickness measurement, measurement device, electromagnetic measurement device, etc., can solve the problems of no calibration method, low spatial resolution, and low board surface flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in more detail below in conjunction with accompanying drawing example:

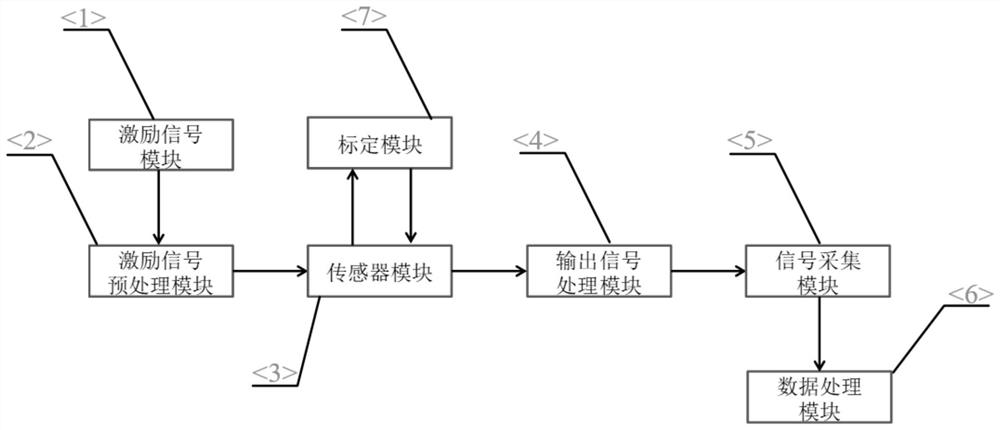

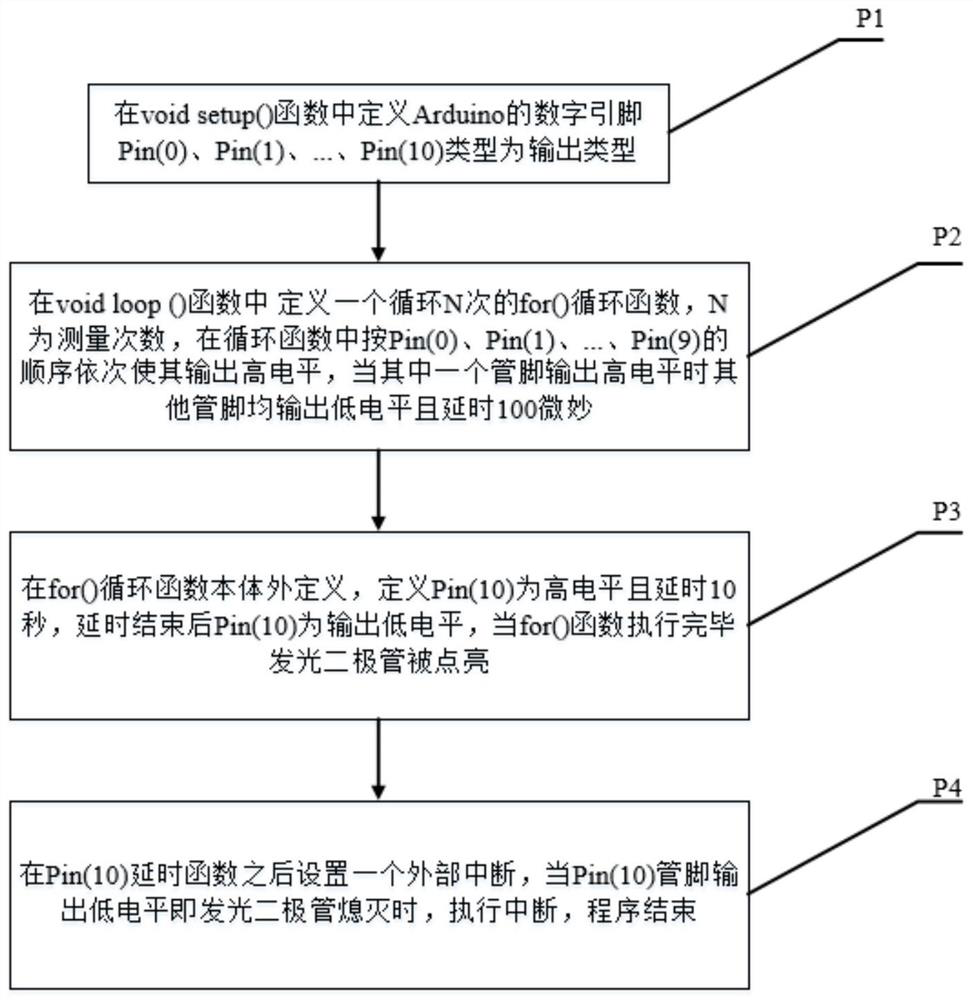

[0044] combine Figure 1-10 , the technical route taken by the present invention is:

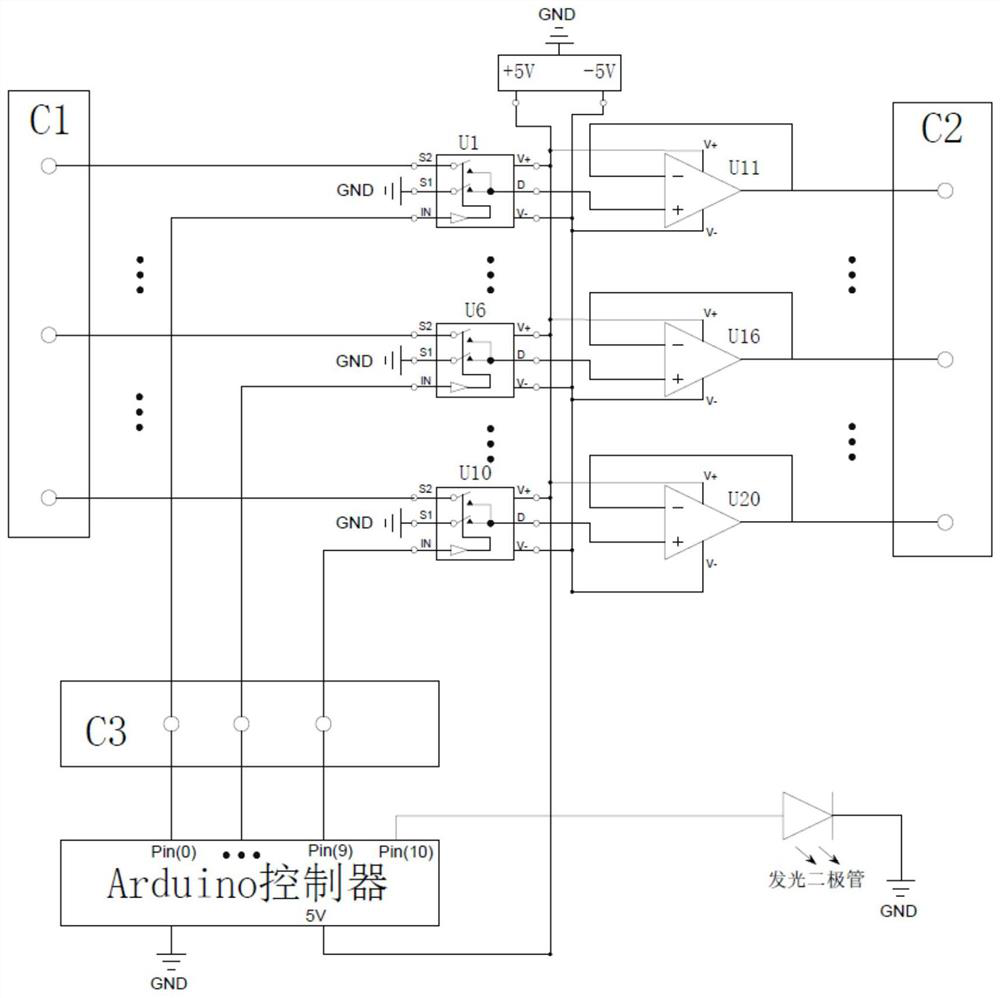

[0045] 1. Use the electromagnetic simulation software to optimize the design of the shape parameters of the emitter 2, the receiver 3 and the ground electrode 4, so that the sensor module can meet the range requirements and have a high spatial resolution, and the ground electrode The existence of 4 can weaken the influence of interfering signals;

[0046] 2. The emitters 2 of each row are individually connected together through the excitation signal input circuit IN, and the receiving electrodes 3 of each column are connected separately through the signal output circuit OUT, and the measurement in the XY plane area can be realized through the structure of rows and columns.

[0047] 3. In order to prevent the intersection between the excitation signal input circuit IN and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com