Motor assembly terminal stud device

A technology for connecting bolts and screw holes, which is applied in the field of motor manufacturing and repair, and can solve the problems that the lead wires cannot penetrate the insulating sleeve, the connection parts of the connecting bolts are loose, and the heat dissipation area of the outlet seat is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

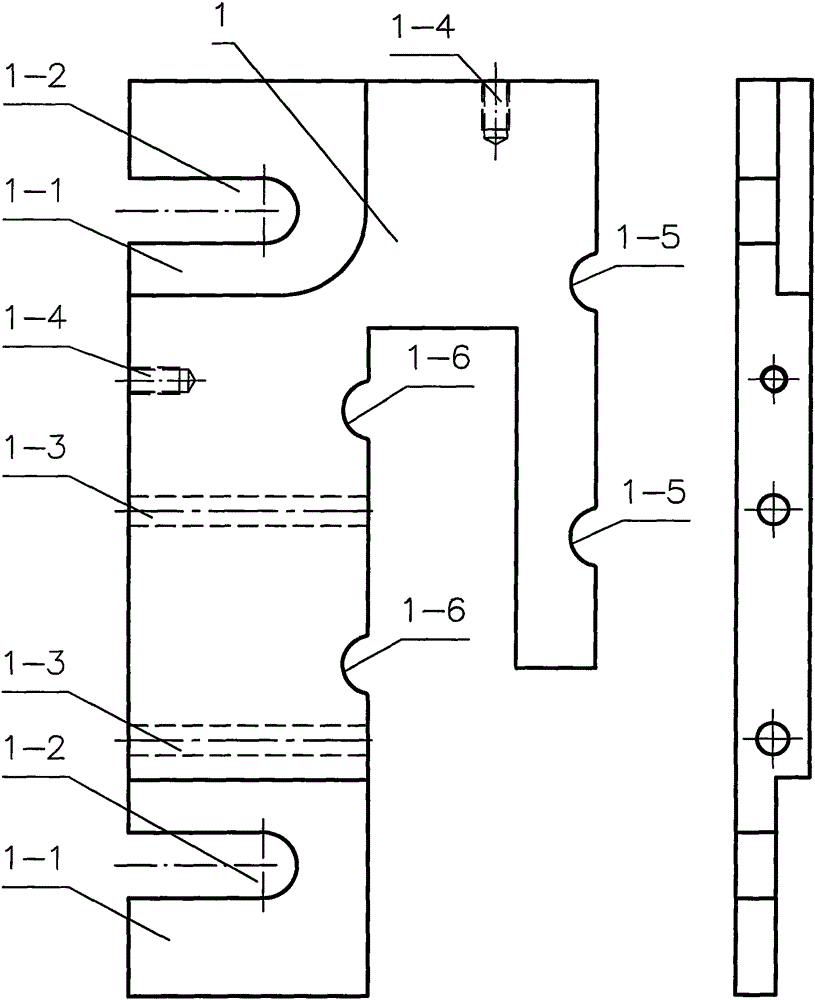

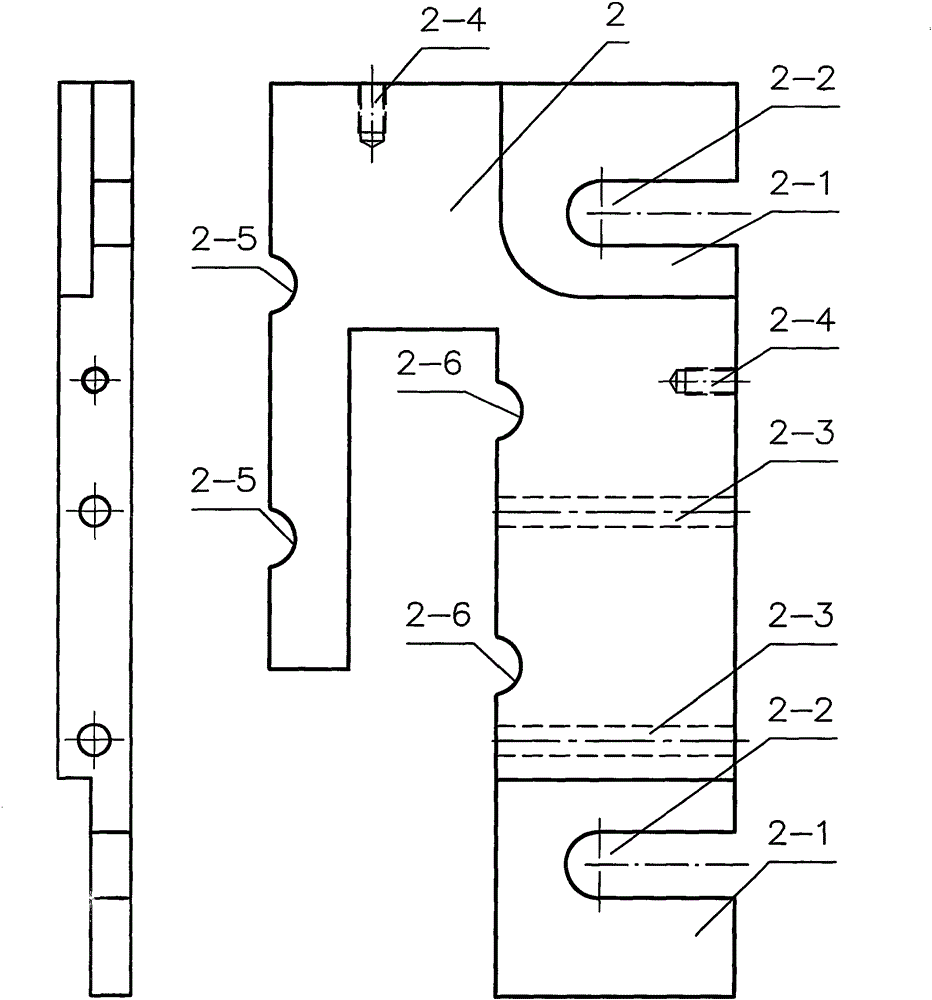

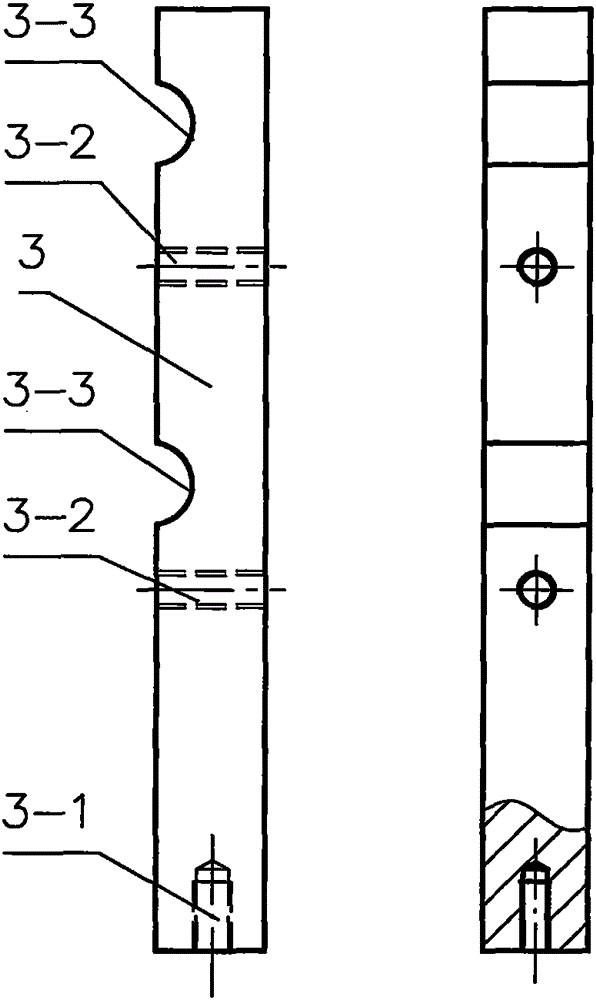

[0012] The motor wiring bolt assembly device is made of metal, which is mainly processed by wire cutting. Semi-circular hole 1-5, semi-circular hole 1-6, semi-circular hole 2-5, semi-circular hole 2-6, semi-circular hole 3-3 are prepared according to different wiring bolt 4 sizes, installation U hole 1-2, installation U hole 2- 2 Match with the size of the base outlet seat 10. The yielding plane 1-1 and the yielding plane 2-1 are processed by milling. The side tightening hole 1-3, the lengthening screw hole 1-4, the side tensioning hole 2-3, the lengthening screw hole 2-4, and the side tightening screw hole 3-2 adopt the drilling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com