Method for producing a coated, chemically prestressed glass substrate having anti-fingerprint properties, and the produced glass substrate

A glass substrate, prestressed technology, applied in the direction of coating, etc., can solve the problems of reducing the durability of double sparse or anti-fingerprint coatings, to improve the rupture strength and scratch resistance, wear resistance and damage resistance, improve The effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

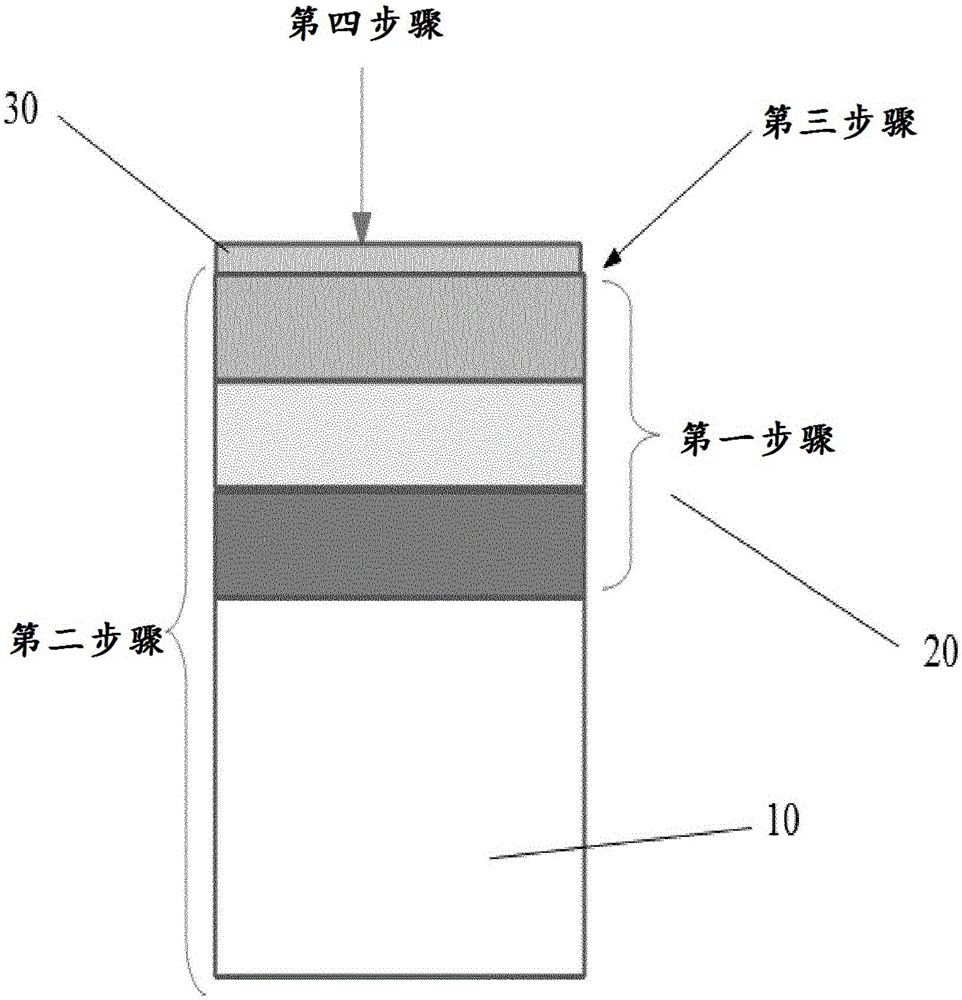

[0210] figure 1 A schematic diagram of a coated glass substrate according to an exemplary embodiment of the present invention is shown.

[0211] A glass substrate 10 , which may also have a structure, is coated with at least one functional layer 20 in a first step according to the method of the invention. The functional layer may be any functional layer within the scope of the present invention, which may be a single layer or a plurality of layers. In the exemplary embodiment shown, this is an antireflection coating consisting of three layers of a medium-refractive, high-refractive and low-refractive layer system. Of course, a further functional layer in the form of a single layer or a multilayer can also be present.

[0212] The glass substrate 10 can also be coated on both sides (not shown).

[0213] In a second step, the coated glass substrate 10 together with the functional coating 20 is chemically prestressed. This is done in a conventional way. The glass substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com