Fruit picking machine scissor

A scissors and fruit machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of no scissors protection, easy to accidentally damage fruit, waste, etc., and achieve the effects of novel design, easy production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

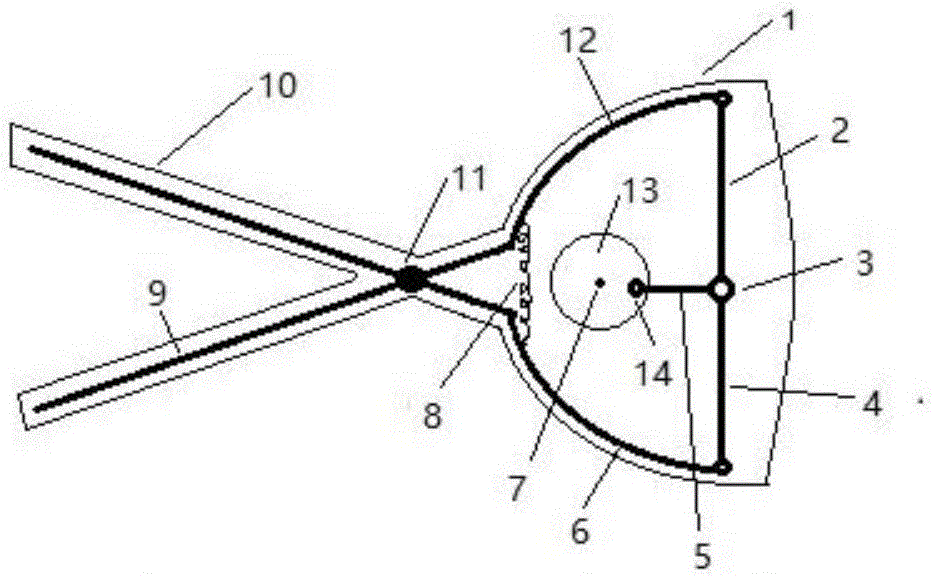

[0011] Such as figure 1 Shown, a kind of fruit picker scissors, comprises scissors rear casing 1, scissors protective casing 10, second pin shaft 11, motor 7 and spring 8, it is characterized in that, described scissors rear casing 1 and scissors protective casing 10 are integrated Design, the motor 7 is fixedly connected with the scissors rear shell 1, the second pin shaft 11 is fixedly connected with the scissors protective shell 10, and a spring 8 is connected between the left end of the upper scissors handle 12 and the left end of the lower scissors handle 6, the first connecting The upper end of the rod 2 is rotationally connected with the right end of the upper scissor handle 12, the lower end of the second connecting rod 4 is rotationally connected with the right end of the lower scissor handle 6, and the left end of the third connecting rod 5 is rotationally connected with the rotating shaft 14 on the running wheel 13. The lower end of the first connecting rod 2, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com