Chocolate milk drink and preparation method thereof

A chocolate and dark chocolate technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of thick taste and high viscosity, and achieve the effect of no precipitation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

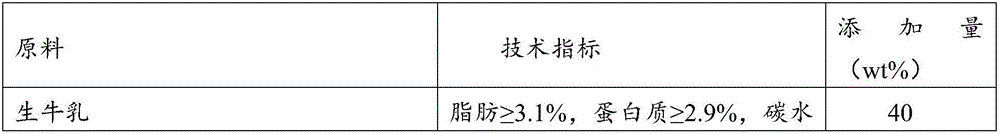

[0044] 1. Raw material formula (see Table 1):

[0045] The raw material formula of table 1 embodiment 1

[0046]

[0047]

[0048] 2. Preparation method:

[0049] (1) Mix cocoa powder and water, the mixing temperature is 85°C, and the mixing time is 30 minutes to obtain material liquid A;

[0050] (2) Mix raw milk, dark chocolate chips, cream, white granulated sugar, stabilizer, emulsifier and water, the mixing temperature is 65°C, and the mixing time is 15 minutes to obtain feed liquid B;

[0051] (3) The material liquid A and the material liquid B are mixed, the mixing temperature is 60° C., and the mixing time is 15 minutes to obtain the mixed liquid C;

[0052] (4) Carry out two-level homogenization of the mixed liquid C obtained in step (3), the first-level homogenization pressure is 15MPa, the second-level homogenization pressure is 5MPa, the second-level homogenization temperature is 50°C, and the homogenized feed liquid Carry out tubular ultra-high temperature...

Embodiment 2

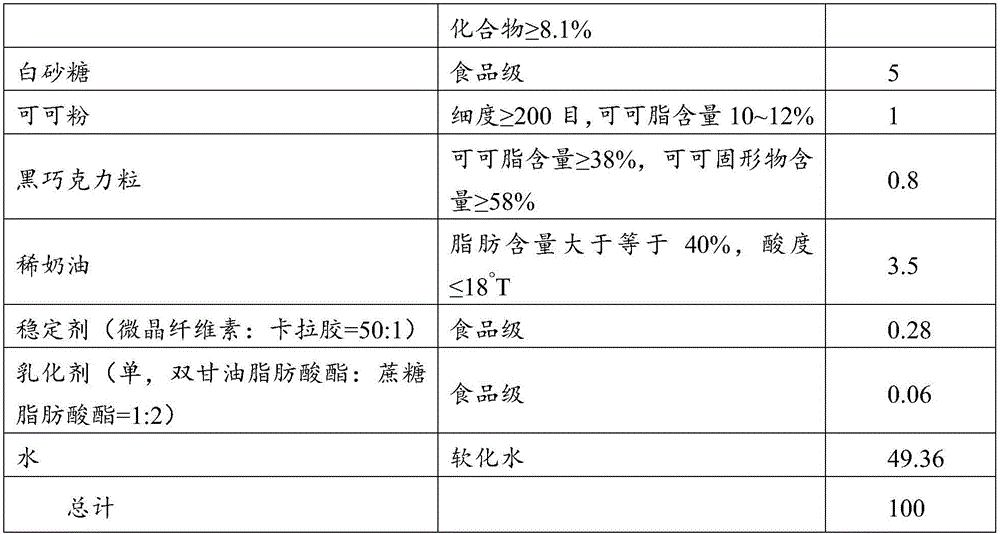

[0056] 1. Raw material formula (see Table 2):

[0057] The raw material formula of table 2 embodiment 2

[0058]

[0059] 2. Preparation method:

[0060] (1) Mix cocoa powder and water, the mixing temperature is 95°C, and the mixing time is 40 minutes to obtain material liquid A;

[0061] (2) Mix raw milk, dark chocolate chips, cream, white granulated sugar, stabilizer, emulsifier and water, the mixing temperature is 70°C, and the mixing time is 20 minutes to obtain feed liquid B;

[0062] (3) The material liquid A and the material liquid B are mixed, the mixing temperature is 65° C., and the mixing time is 20 minutes to obtain the mixed liquid C;

[0063] (4) Perform two-stage homogenization of the mixed liquid C obtained in step (3), the first-stage pressure is 20MPa, the second-stage pressure is 10MPa, the homogenization temperature is 65°C, and the homogenized feed liquid is subjected to tubular ultra-high temperature sterilization , the sterilization temperature was 1...

Embodiment 3

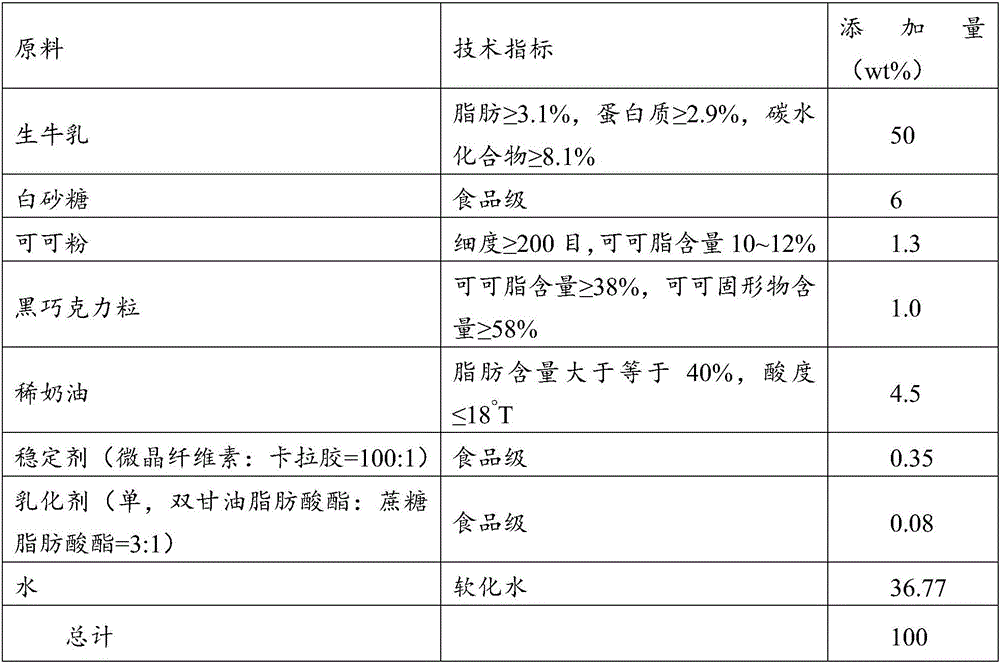

[0067] 1. Raw material formula (see Table 3):

[0068] The raw material formula of table 3 embodiment 3

[0069]

[0070] 2. Preparation method:

[0071] (1) Mix cocoa powder and water, the mixing temperature is 85°C, and the mixing time is 40 minutes to obtain material liquid A;

[0072] (2) Mix raw milk, dark chocolate chips, cream, white granulated sugar, stabilizer, emulsifier and water, the mixing temperature is 65°C, and the mixing time is 20 minutes to obtain feed liquid B;

[0073] (3) The material liquid A and the material liquid B are mixed, the mixing temperature is 65° C., and the mixing time is 20 minutes to obtain the mixed liquid C;

[0074] (4) Carry out secondary homogenization of the mixed liquid C obtained in step (3), the first stage pressure is 15MPa, the second stage pressure is 5MPa, the homogenization temperature is 65°C, and the homogenized feed liquid is subjected to tubular ultra-high temperature sterilization, sterilization The temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com