Self-suction type cleaning trolley filter cloth bag vibration dust collection device

A technology of dust removal device and cleaning vehicle, applied in membrane filter, dispersed particle filtration, gas treatment and other directions, can solve the problems of reducing fan suction, existence of dead angle, difficult to clean, etc., to ensure filtering effect, ensure fan suction, compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

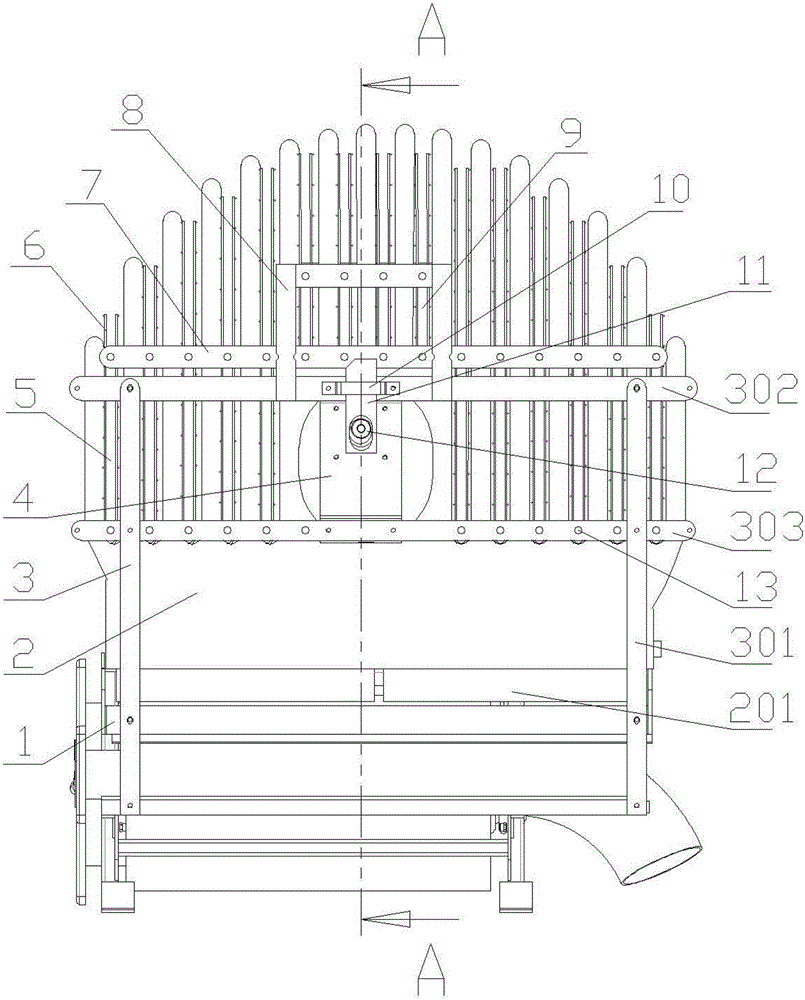

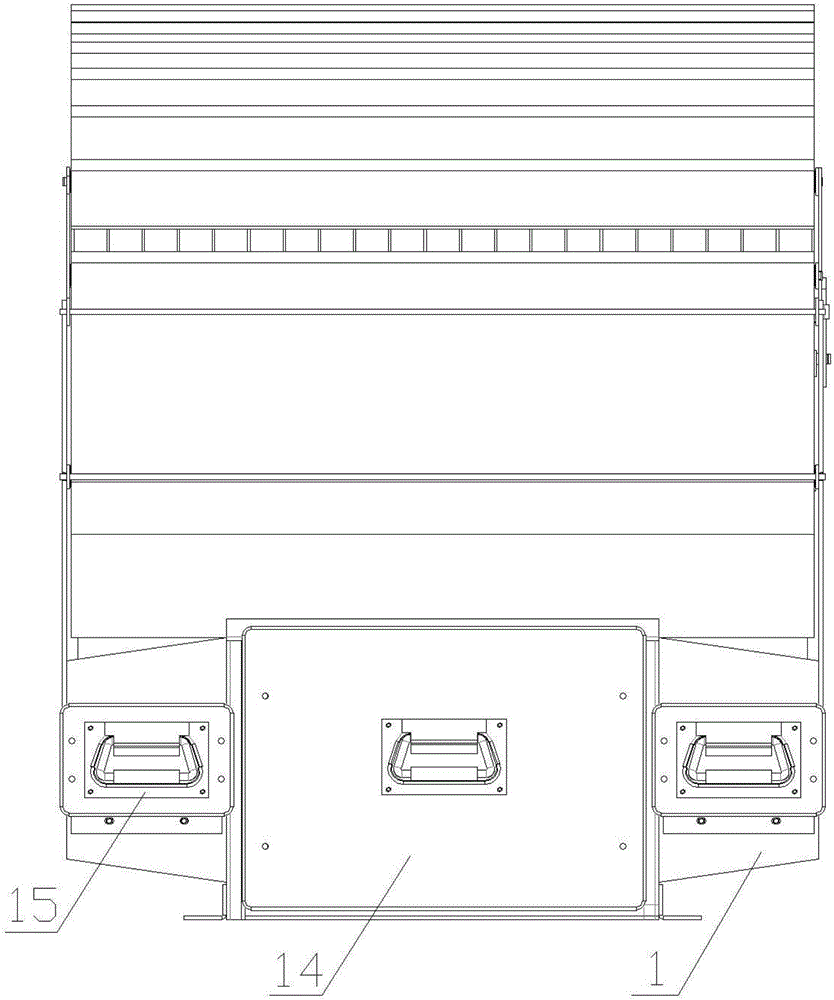

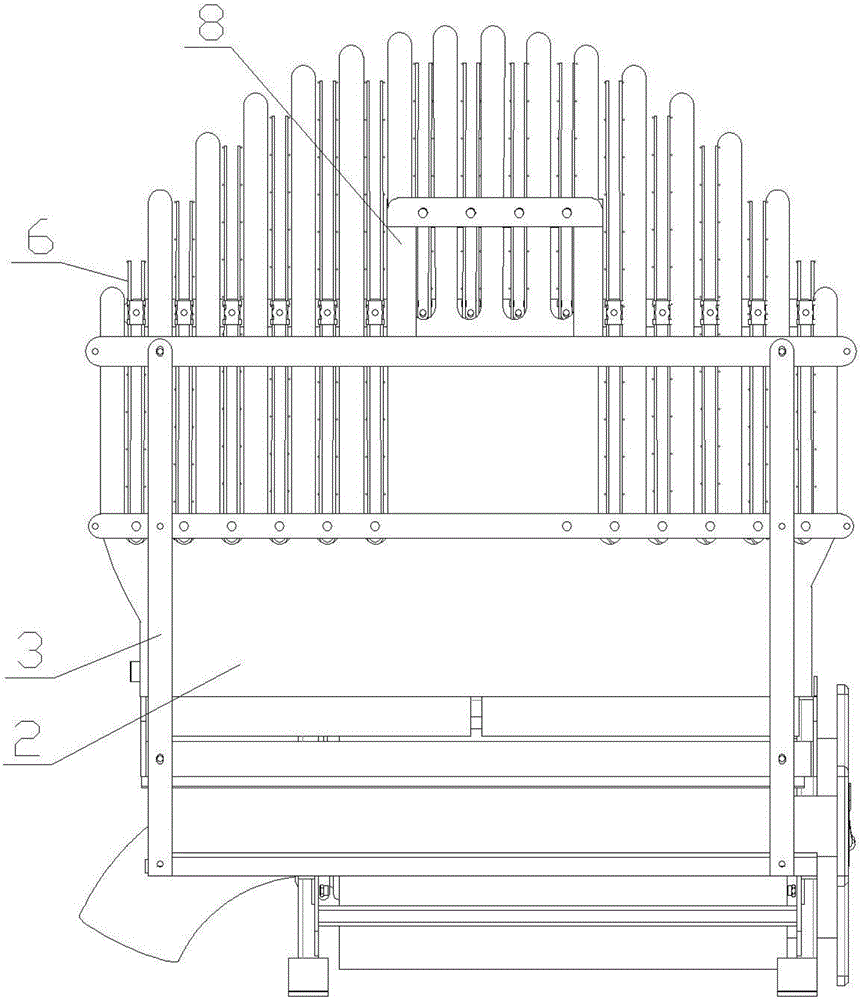

[0026] Such as Figure 1-Figure 5 As shown, a self-priming cleaning vehicle filter bag vibration dust removal device related to the present invention includes a filter bag 2 and a plurality of metal grid frames 6 with U-shaped cross-sections, the upper part of the filter bag 2 is a circular layered structure, and the filter bag The bottom of 2 is provided with a dust inlet and four settling ports 201. The four settling ports 201 are distributed on both sides of the dust inlet. A plurality of metal mesh frames 6 are of different heights and are respectively spaced between adjacent two-layer cloth bags on the upper part of the filter cloth bag 2 to limit the expansion of the filter cloth bag 2 . Both sides of the filter bag 2 are respectively provided with interconnected bag holders 3, and the bag holders 3 are respectively connected by two vertically arranged vertical plates 301 and the upper horizontal plate 302 and the lower horizontal plate 303 connecting the two vertical pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com