UV LED line light source curing machine

A technology of curing machine and line light source, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of inconspicuousness, cannot increase too much, and the effect is not satisfactory, etc., and achieve the illumination intensity of the light source. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

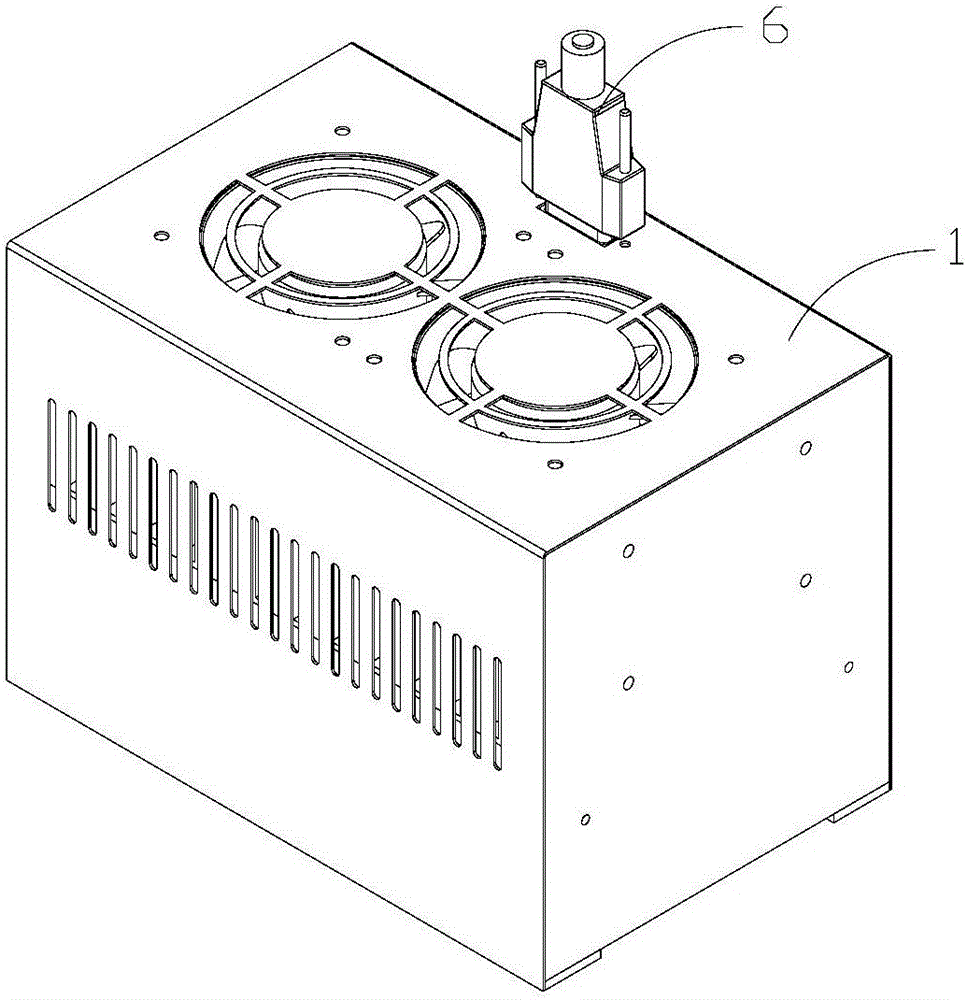

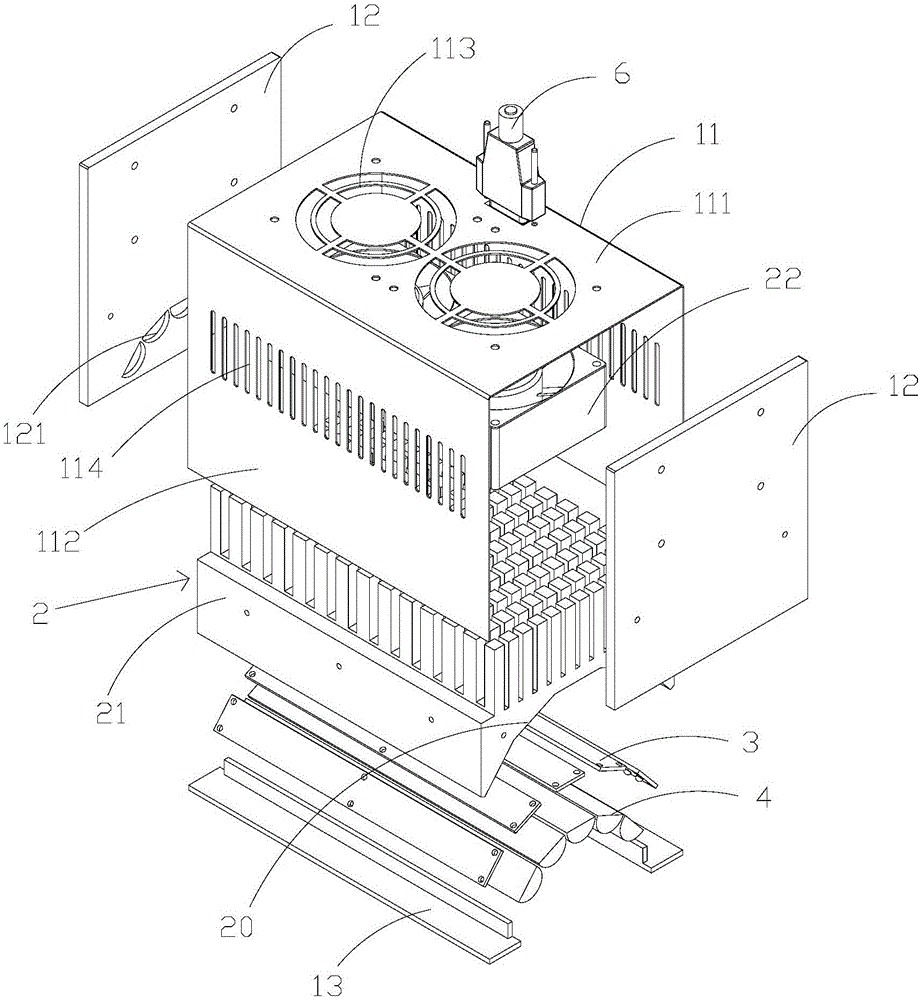

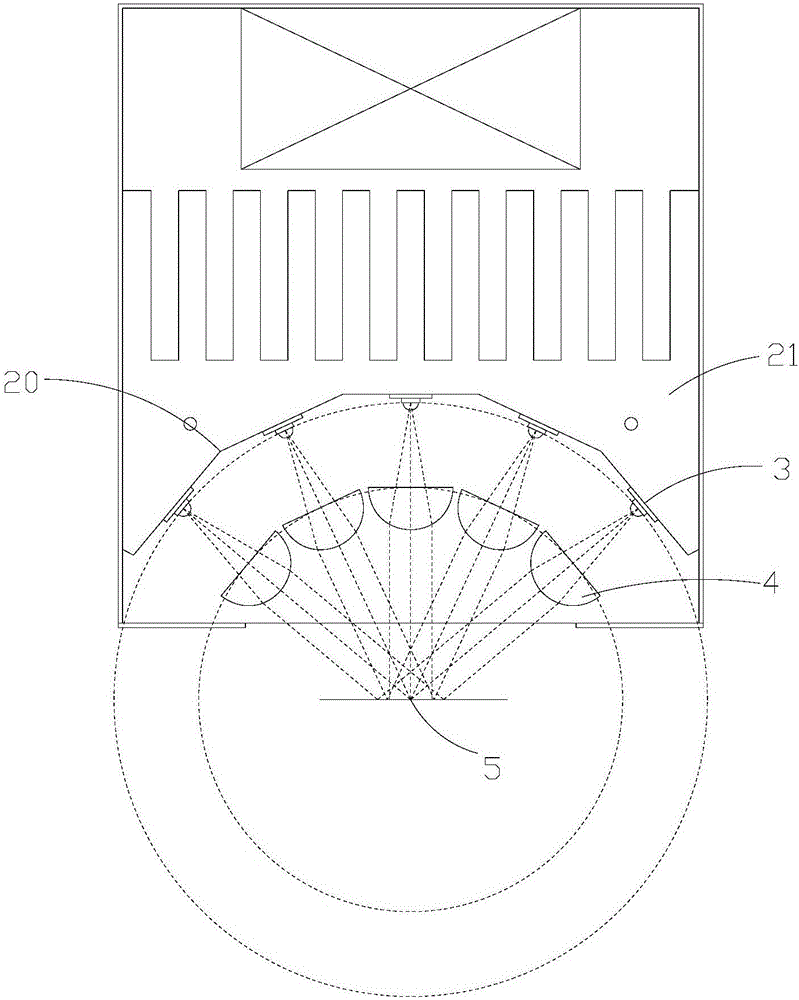

[0019] Such as figure 1 and figure 2 As shown, in some embodiments of the present invention, the UV LED line light source curing machine includes a housing 1 and a heat dissipation device 2 fixedly installed in the housing, several UV LED light source boards 3 and several convex lenses 4, the heat dissipation device 2 A concave surface 20 is formed at the front end of the UV LED light source board 3, and the UV LED light source boards 3 are fixedly installed side by side on the concave surface 20 of the heat sink 2, and the light-emitting axes of the UV LED light source boards 3 converge at a converging point, and each convex lens 4 is correspondingly fixedly installed on the The front end of each UV LED light source plate 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com