Backlight module and MiniLED display device

A backlight module and backplane technology, applied in the field of display screens, can solve problems such as complicated ink layer printing, non-compliance with ultra-thinness, and increased light mixing distance, so as to improve uneven brightness and darkness, shorten light mixing distance, and improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

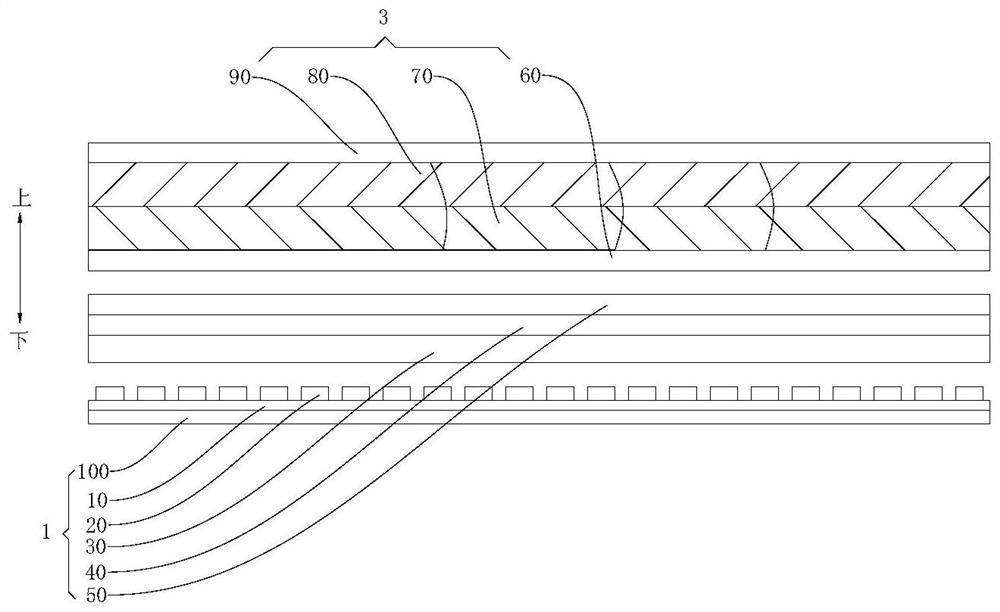

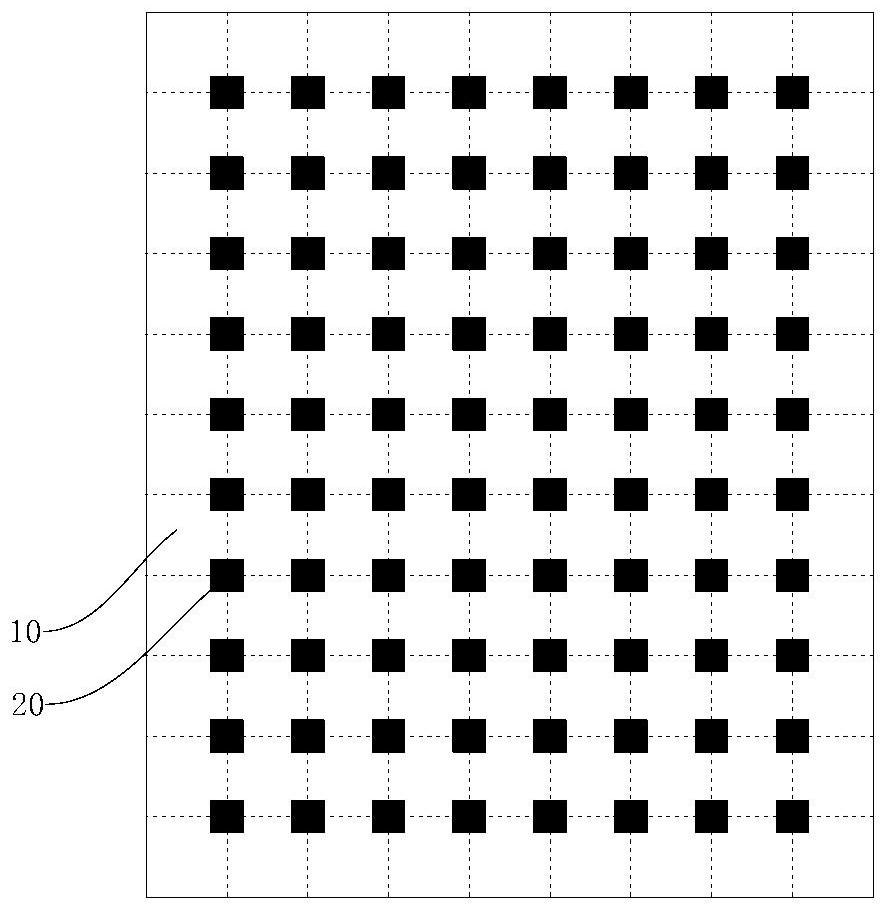

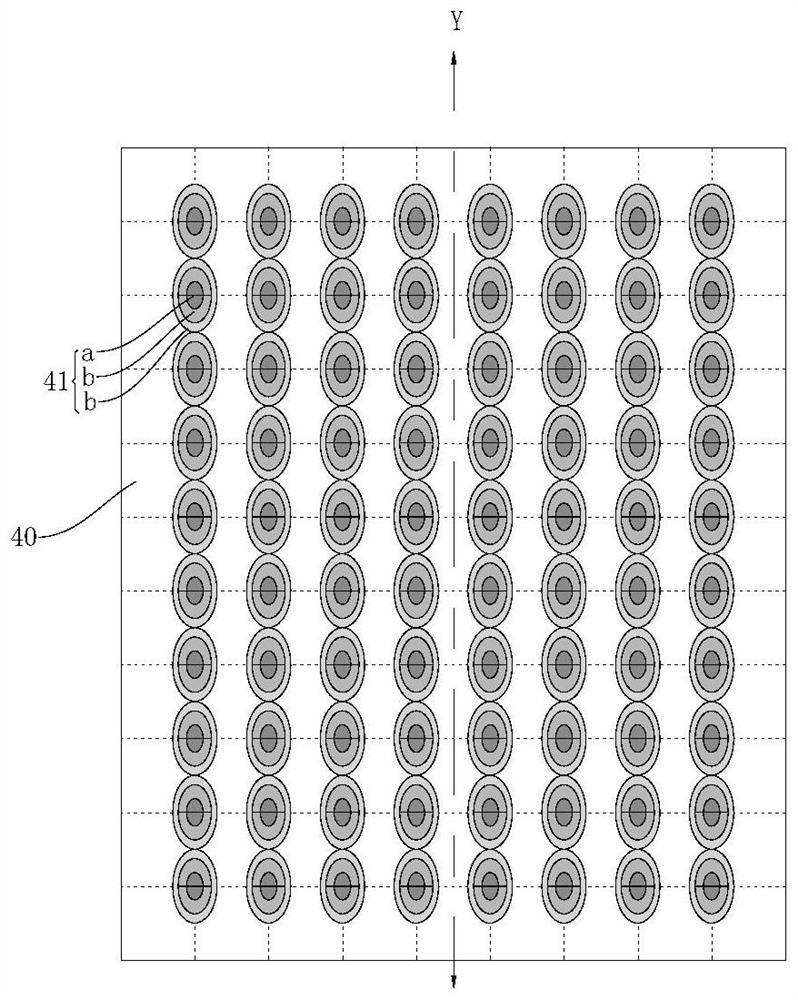

[0071] as Figure 3 and Figure 4 As shown, the first optical film layer 40 is provided with a first ink pattern 41, as shown Figure 5As shown, the second optical film layer 50 is provided with a second ink pattern 51, the center axis of the first ink pattern 41 and the center axis of the second ink pattern 51 are coincident with the central axis of the luminous body 20, the first ink pattern 41 and the second ink pattern 51 are ovals of the same size and shape, the long axis of the first ink pattern 41 is parallel to the Y axis direction, the long axis of the second ink pattern 51 is parallel to the X axis direction, and the first ink pattern 41 can be reconnected with the second ink pattern 51 by rotating 90 °. The first ink pattern 41 and the second ink pattern 51 both include a first shading region a and two second shading region b. as Figure 6 and Figure 7 As shown, after the projection superposition of the reference plane 2 forms at least three regions of different transmittan...

Embodiment 2

[0073] as Figure 9 As shown, the first optical film layer 40 is provided with a first ink pattern 41, as shown Figure 10 As shown, the second optical film layer 50 is provided with a second ink pattern 51, the central axis of the first ink pattern 41 and the central axis of the second ink pattern 51 coincide with the central axis of the luminous body 20, the first ink pattern 41 and the second ink pattern 51 are circular in the same shape but of different sizes, the size of the first ink pattern 41 is larger than the size of the second ink pattern 51, accordingly, the first ink pattern 41 and the second ink pattern 51 both include a first coloring region a and the same number of second coloring region b. The first shading region a of the first ink pattern 41, the first shading region a and the second shading region b of the first ink pattern 41 and the corresponding first shading region a and the second shading area b of the second ink pattern 51 are larger, and when the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com