Light emitting assembly, backlight module and liquid crystal display

A technology of a light-emitting component and a backlight module, which is applied to semiconductor devices of light-emitting components, optical components, instruments, etc., and can solve problems such as uneven brightness and darkness of the backlight module, reduced luminous efficacy of the light-emitting component 1a, and reduced luminous efficacy of the light-emitting component 1b, etc. To achieve the effect of improving luminous efficacy, improving uneven brightness and darkness, and high luminous efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

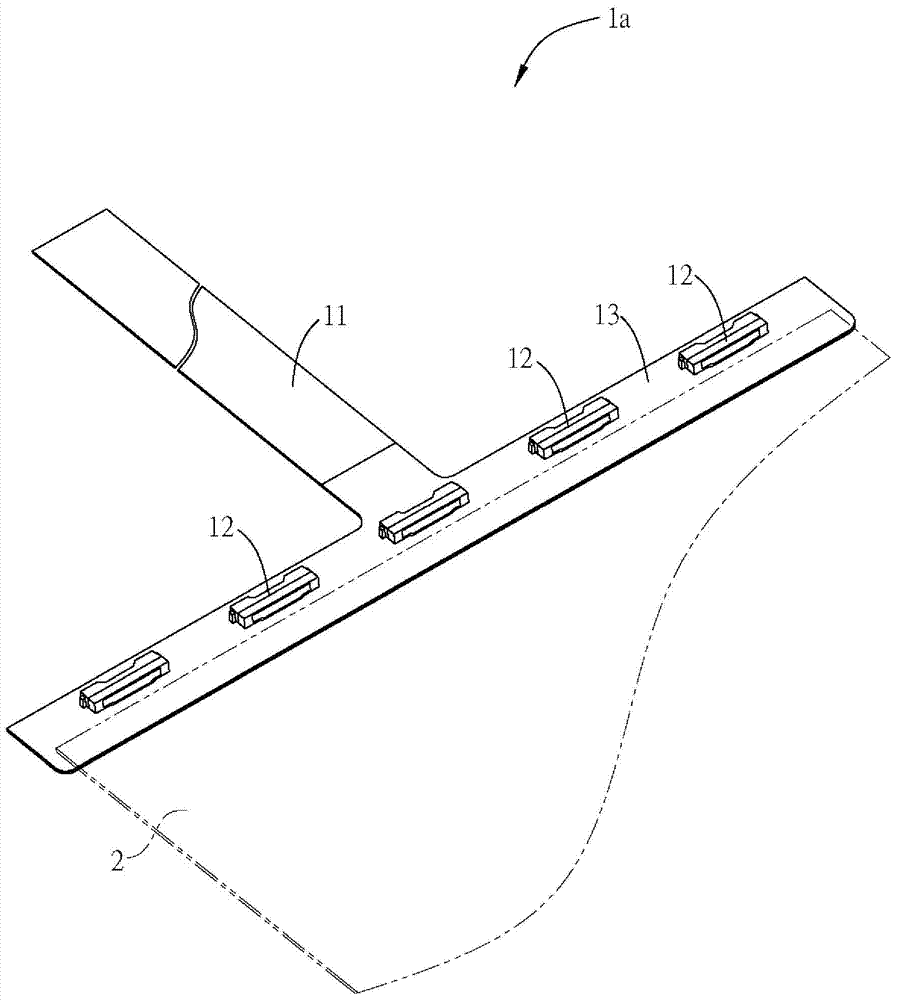

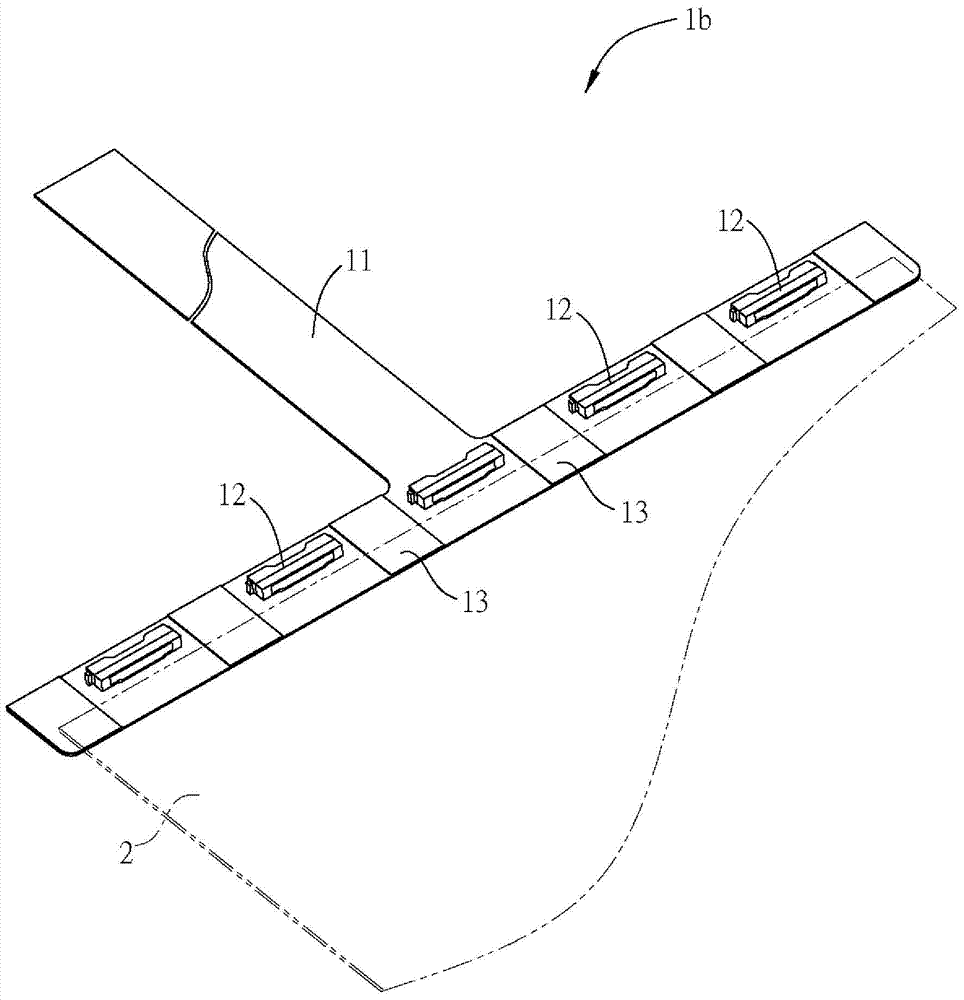

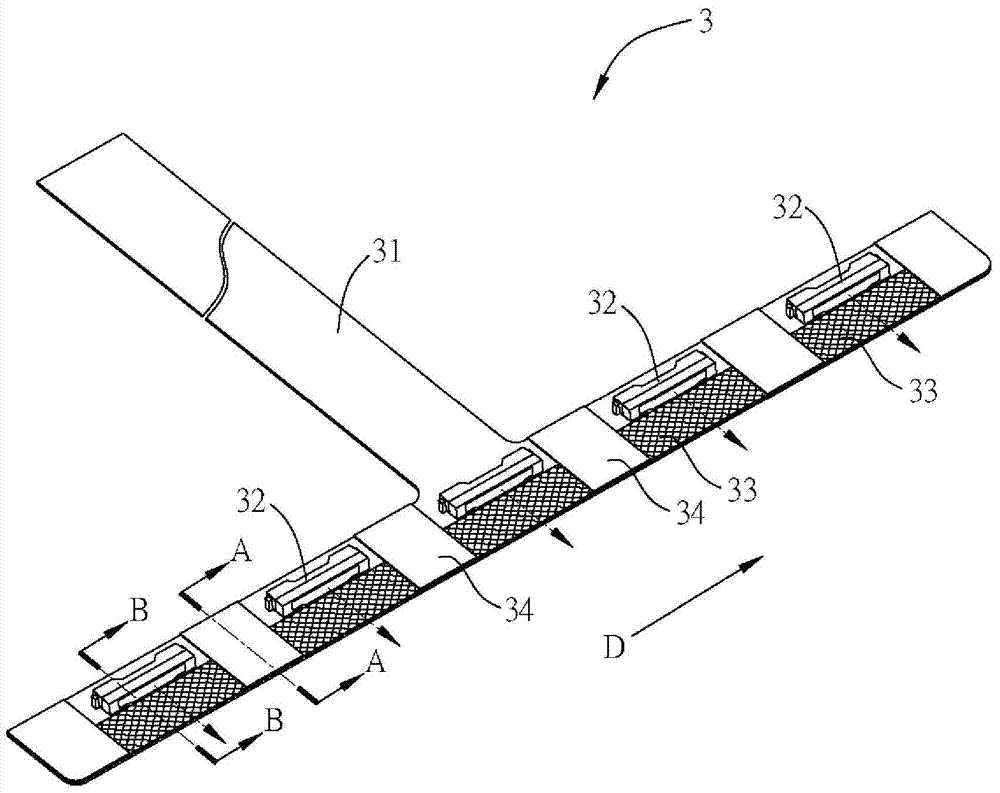

[0051] Please refer to Figure 2A to Figure 2E As shown, among them, Figure 2A It is a three-dimensional schematic diagram of a light-emitting component 3 in a preferred embodiment of the present invention, Figure 2B for Figure 2A , the schematic cross-sectional view of line A-A, Figure 2C for Figure 2A , the schematic cross-sectional view of the line B-B, Figure 2D for Figure 2A The partially enlarged schematic diagram of the light-emitting component 3, and Figure 2E for Figure 2A A schematic partial top view of the light-emitting assembly 3 of FIG. The light-emitting component 3 can be applied, for example but not limited, to a light-emitting source of a side-mounted backlight module of a flat-panel display dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com