Light guide plate, backlight module and display device

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problem of uneven brightness, and achieve the effect of improving brightness uniformity and improving brightness and darkness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

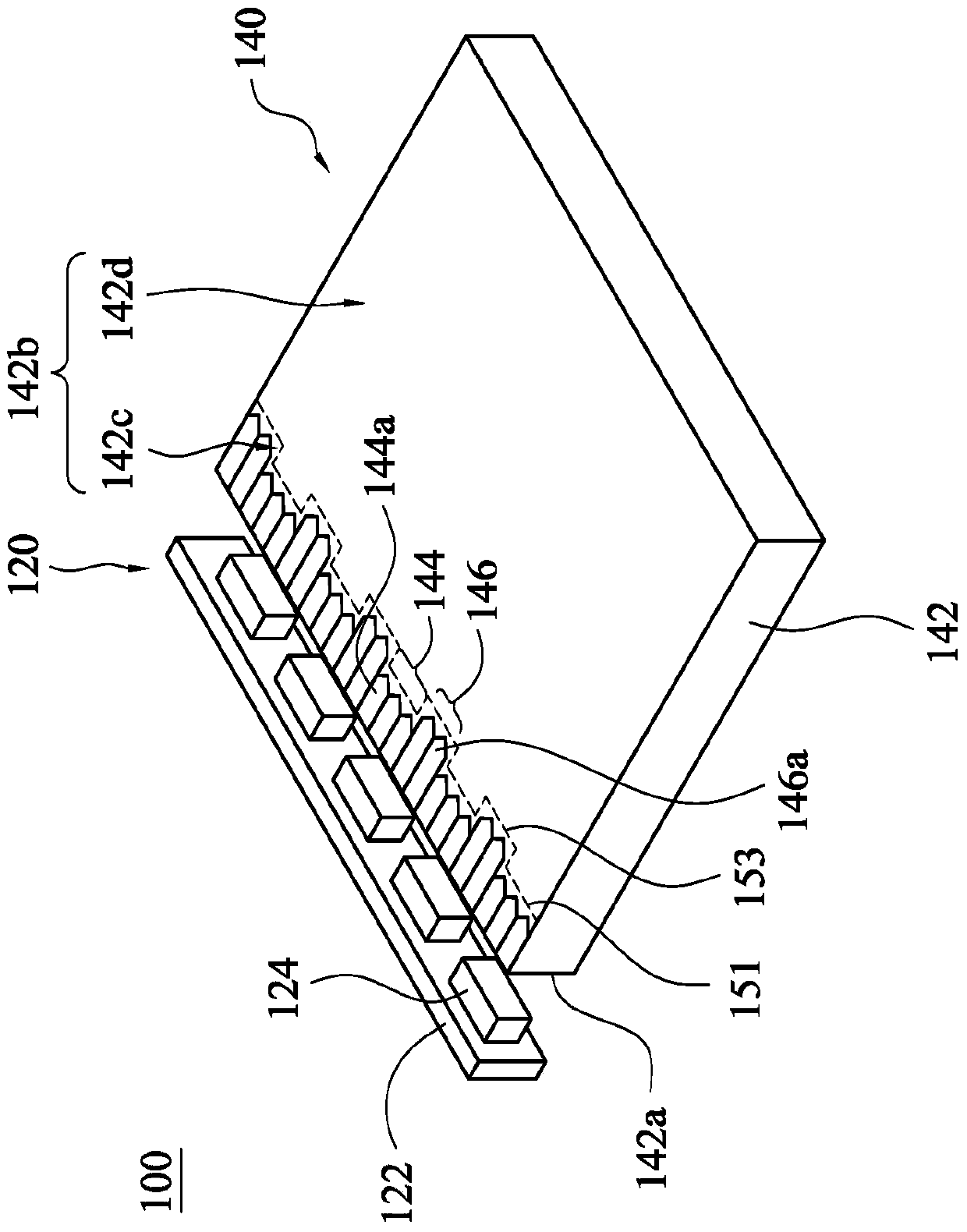

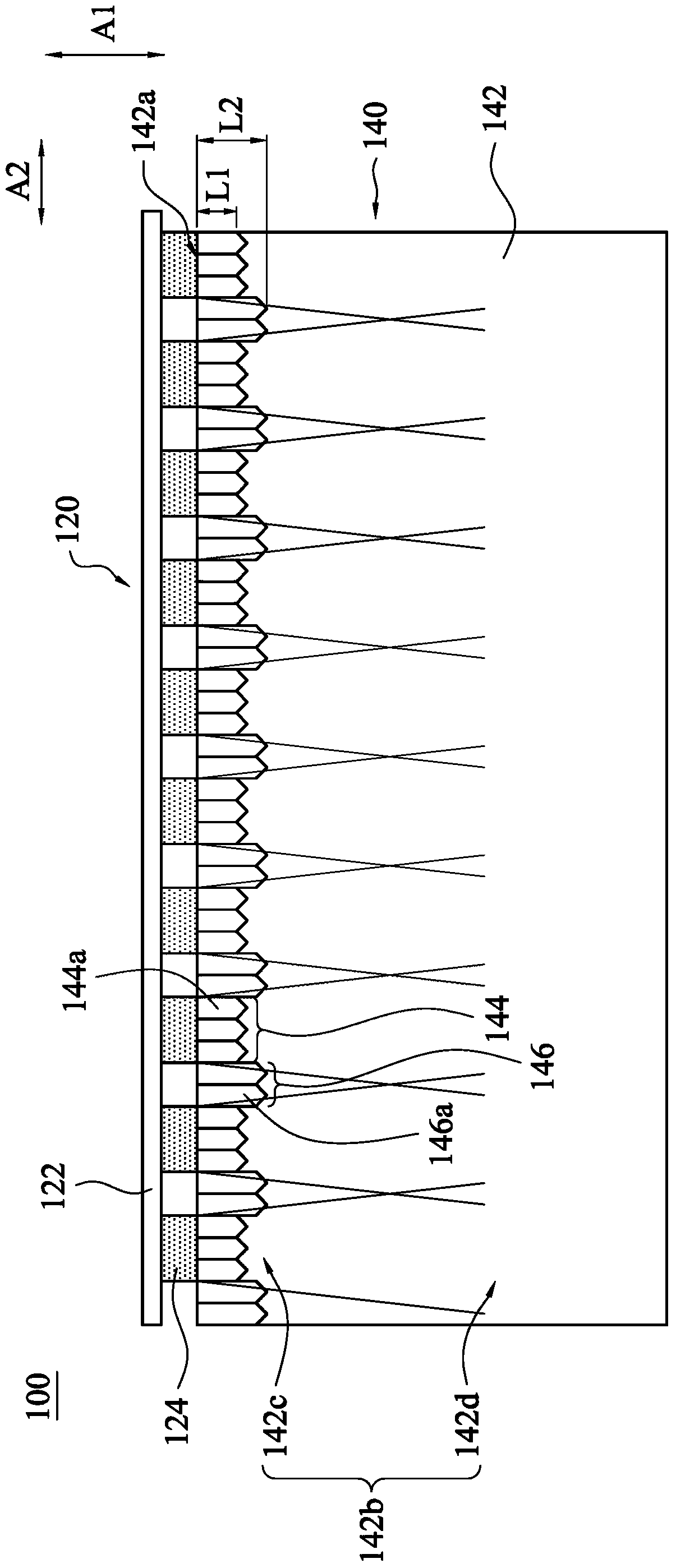

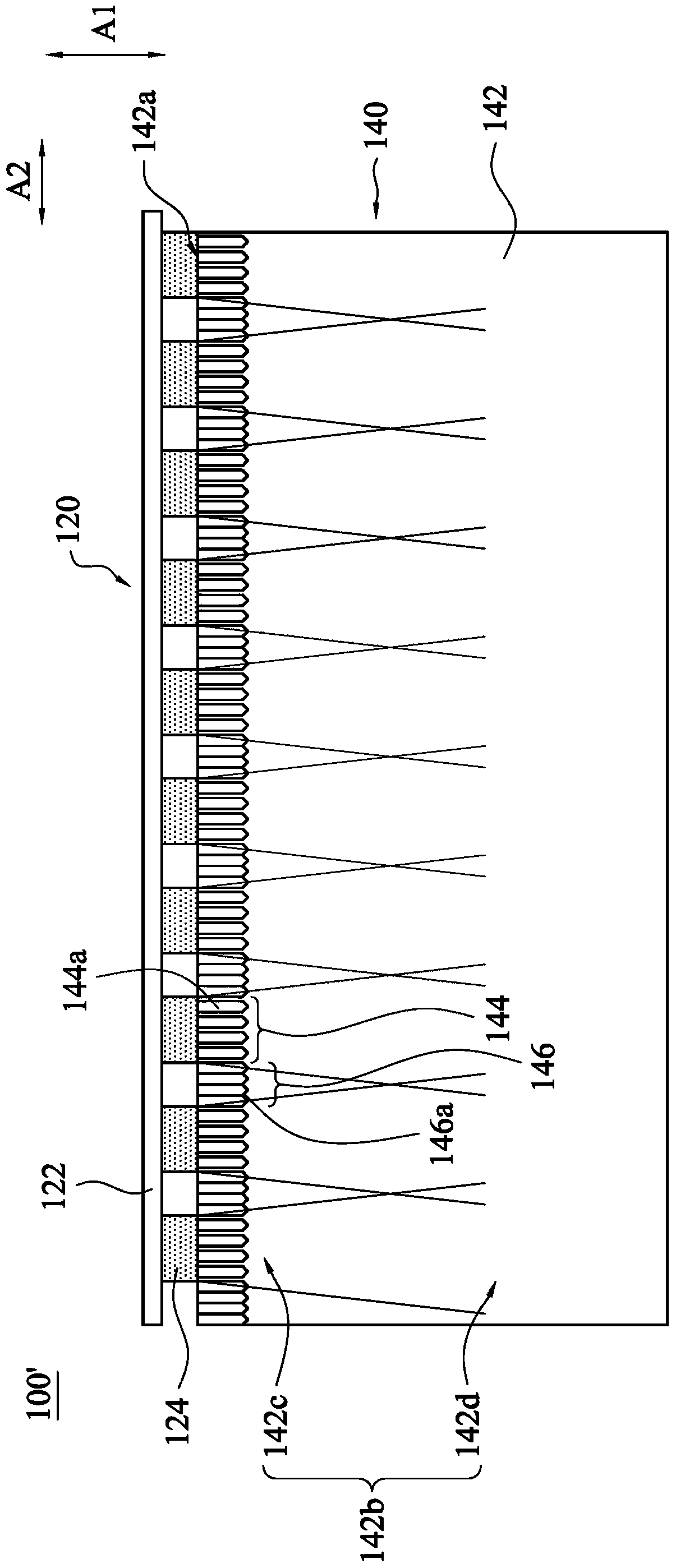

[0041] Also refer to Figure 1A and Figure 1B , which are respectively a device schematic diagram and a top view describing a backlight module according to the first embodiment of the present invention. The backlight module 100 of this embodiment mainly includes a light source 120 and a light guide plate 140 . The light guide plate 140 mainly includes a main body 142 , a plurality of first microstructure regions 144 and a plurality of second microstructure regions 146 . The first microstructure region 144 and the second microstructure region 146 are disposed on the main body 142, and through the first microstructure region 144 and the second microstructure region 146, the light leakage of the light guide plate 140 close to the light incident can be effectively atomized, and the The phenomenon of uneven brightness and darkness near the light incident can be greatly improved, thereby improving the brightness uniformity of the overall backlight module 100 .

[0042] Continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com