Galvanized sheet washing device

A cleaning device and galvanized sheet technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of low cleaning process efficiency, unclean cleaning water, etc., and achieve water saving resources, improve cleaning efficiency, and improve the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

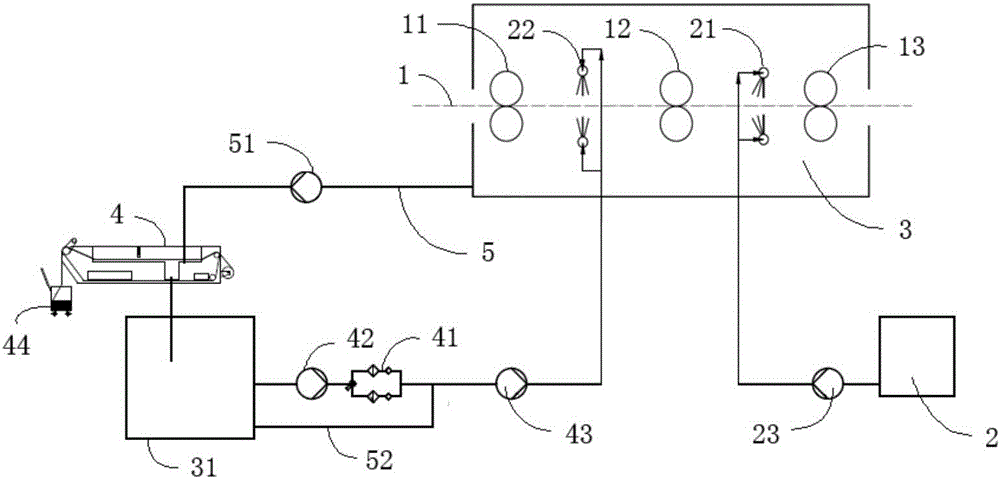

[0017] Such as figure 1 As shown, a kind of galvanized sheet cleaning device provided by the present invention comprises a galvanized sheet 1, a splash-proof roll 11, a first non-woven fabric roll 12, a second non-woven fabric roll 13, a desalted water tank 2. A rinse nozzle 21, a high-pressure nozzle 22, a low-pressure water pump 23, a sink 3, a high-pressure water tank 31, a flat bed filter 4, a double-tube filter 41, a filter pump 42, a high-pressure water pump 43, a garbage Recovery bucket 44 , a flow guide pipe 5 , a recovery water pump 51 , and a return pipe 52 .

[0018] The anti-splash roller 11, the first non-woven fabric roll 12 and the second non-woven fabric roll 13 are successively arranged on the galv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap