A system for online detection of friction coefficient of cold-rolled plate surface and its application method

A surface friction and cold-rolled plate technology, applied in metal rolling, length measuring device, metal rolling, etc., can solve the problems of long detection cycle and inability to provide data by on-site operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

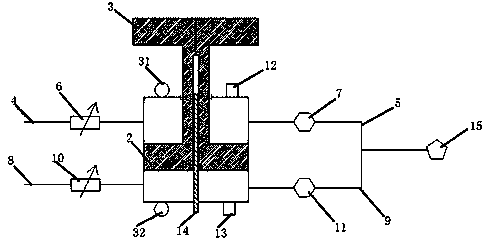

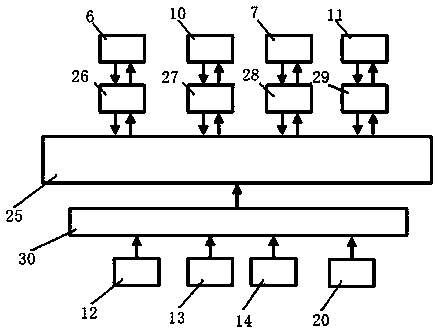

[0059] The present invention is a system for online detection of surface friction coefficient of cold-rolled plate, comprising 2 hydraulic cylinders, surface friction coefficient detection device and process control system;

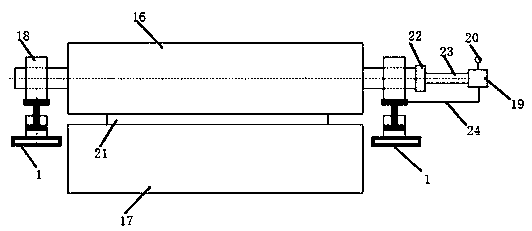

[0060] figure 1 It shows that two hydraulic cylinders are respectively fixed on the hydraulic cylinder support 1, and the piston 2 of each hydraulic cylinder divides the hydraulic cylinder into an upper chamber and a lower chamber, and the upper chamber is connected with the upper chamber oil inlet pipe 4 and the upper chamber oil outlet pipe 5, and the upper chamber The upper chamber electromagnetic regulating valve 6 is installed on the oil inlet pipe 4, the upper chamber electromagnetic switch valve 7 is installed on the upper chamber oil outlet pipe 5; the lower chamber is connected with the lower chamber oil inlet pipe 8 and the lower chamber oil outlet pipe 9, and the lower chamber is installed on the lower chamber oil inlet pipe 8 Electromagnetic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com