Riveting stake and automatic drilling riveter

A riveting anvil and claw finger technology, which is applied in the field of upper riveting anvils and automatic drilling and riveting machines, can solve problems such as inability to discharge rivets, achieve the effect of avoiding rivet indentation, and improving riveting quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

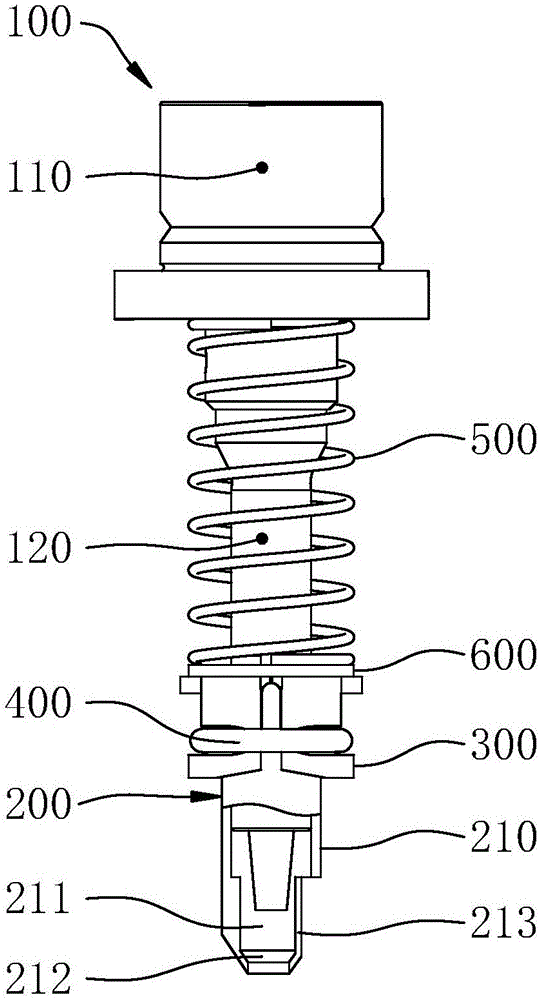

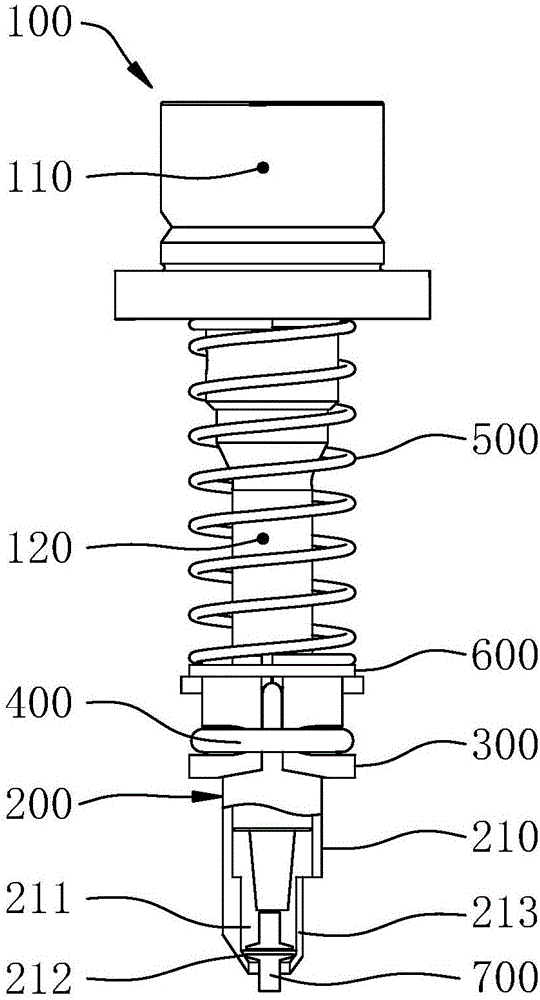

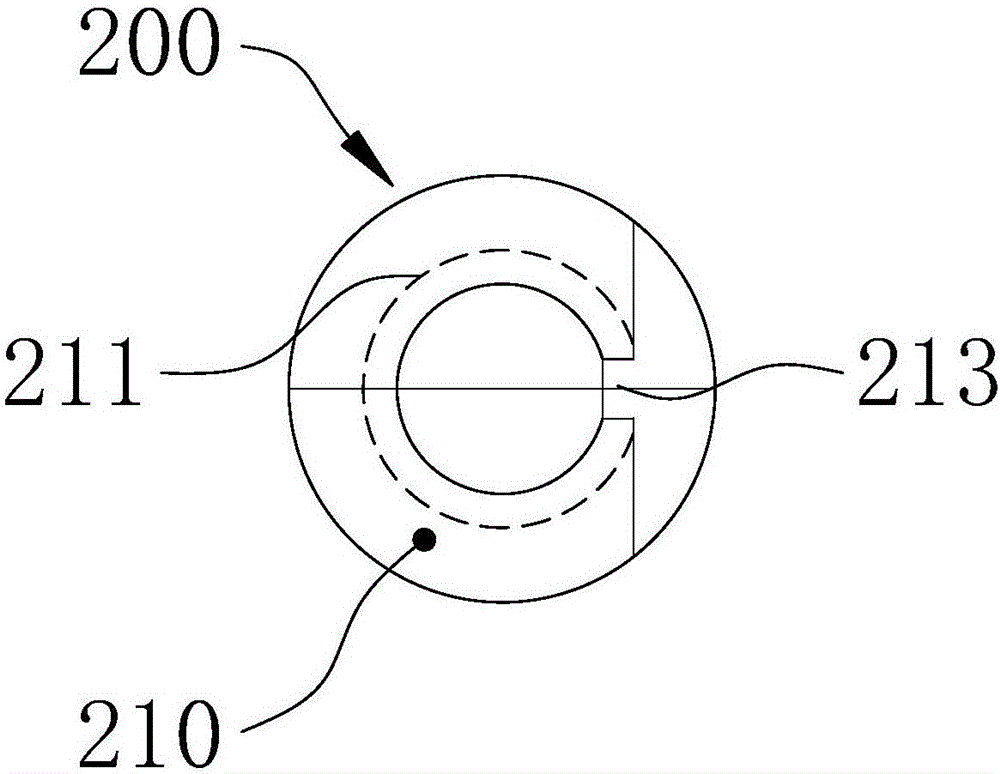

[0019] combine Figure 4 with Image 6 As shown, the upper riveting anvil includes nail claws 200. The nail claws 200 are composed of two claw fingers 210 arranged symmetrically. There is a semi-circular groove 211 on the top, and the semi-circular groove 211 on each claw finger 210 can jointly form a nail groove for clamping the rivet 700 after the two claw fingers 210 are fitted together as a whole. The lower end of the nail groove is tapered One of the seams where the two claw fingers 210 are attached is provided with a nail entry opening 213 connecting the nail groove and the outside world; the other seam where the two claw fingers 210 are attached is provided with an extrusion gap 214, The extrusion notch 214 includes a structural surface perpendicular to the other seam, the structural surface being tangent to the nail groove. The extrusion notch 214 corresponds to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com