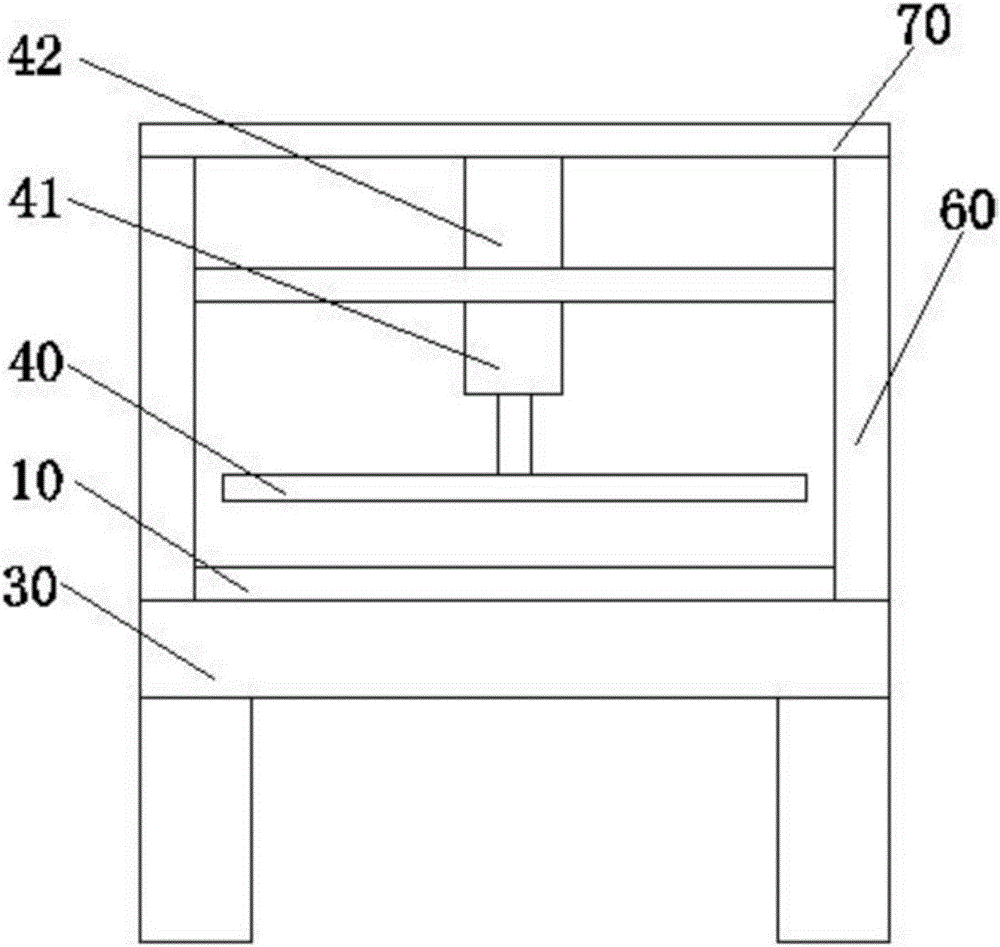

Key feeding mechanism

A key and material tray technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, high scrap rate, cumbersome operation, etc., to improve work efficiency, simple action, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] The rest is the same as the first embodiment, the difference is that the second paddle is facing the right side of a group of buttons arranged at the rearmost end, and the left side of the rear end of the tray is provided with a loading manipulator for assembling the buttons. The table top of the workbench has the degree of freedom to tilt to the lower left side, the right side of the table top of the workbench is hingedly connected with the frame of the workbench, and the left side of the table top of the workbench is arranged on the frame of the workbench and can be horizontal The telescoping support shaft supports the connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com