Pump workpiece eccentricity circle machining tooling and use method thereof

A technology of eccentric circle and tooling, which is applied in the direction of metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of reducing work efficiency, reducing the effective utilization rate of CNC lathe equipment, and low processing accuracy, so as to improve processing efficiency and The effects of processing accuracy, improving equipment utilization, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

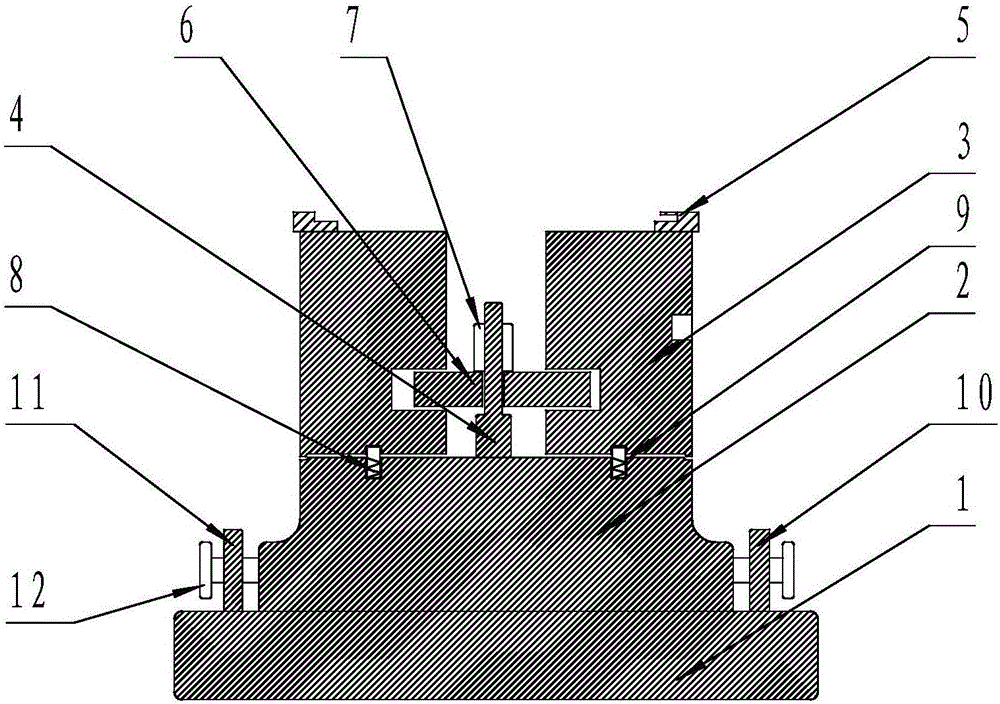

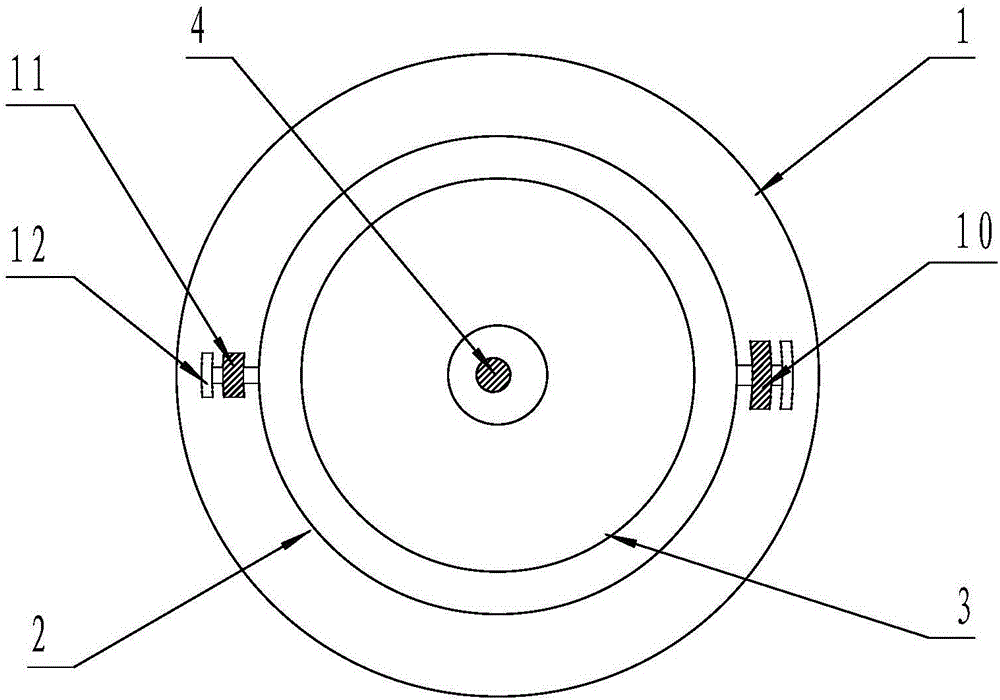

[0020] Such as figure 1 , figure 2 As shown, an eccentric circle machining tool for a water pump workpiece is characterized by comprising a tool base 1, a connecting plate 2, a three-jaw chuck 3, the connecting plate 2 is bolted to the tool base 1, and the axis of the connecting plate 2 It is a straight line with the axis of the tooling base 1, a positioning shaft 4 is provided on the side of the connecting plate 2 away from the tooling base 1, the upper outer surface of the positioning shaft 4 is provided with external threads, and the top of the three-jaw chuck 3 There are three movable jaws 5 capable of clamping the workpiece to be processed, the three-jaw chuck 3 has a through hole arranged along the vertical axis, and the three-jaw chuck 3 is internally provided on the lower side to cover the setting of the three-jaw chuck The movable sliding plate 6 with a through hole is provided with a through hole with the same diameter as the positioning shaft 4, and the positioning ...

Embodiment 2

[0027] Such as figure 1 , figure 2 As shown, an eccentric circle machining tool for a water pump workpiece is characterized by comprising a tool base 1, a connecting plate 2, a three-jaw chuck 3, the connecting plate 2 is bolted to the tool base 1, and the axis of the connecting plate 2 It is a straight line with the axis of the tooling base 1, a positioning shaft 4 is provided on the side of the connecting plate 2 away from the tooling base 1, the upper outer surface of the positioning shaft 4 is provided with external threads, and the top of the three-jaw chuck 3 There are three movable jaws 5 capable of clamping the workpiece to be processed, the three-jaw chuck 3 has a through hole arranged along the vertical axis, and the three-jaw chuck 3 is internally provided on the lower side to cover the setting of the three-jaw chuck The movable sliding plate 6 with a through hole is provided with a through hole with the same diameter as the positioning shaft 4, and the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com