Low pressure turbine blade shroud processing device and method

A low-pressure turbine and processing device technology, applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problem of low processing efficiency, unstable size of low-pressure turbine blades, and easy burns and cracks in processing sealing teeth and other problems, to improve processing efficiency, prevent burn phenomenon, and save quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

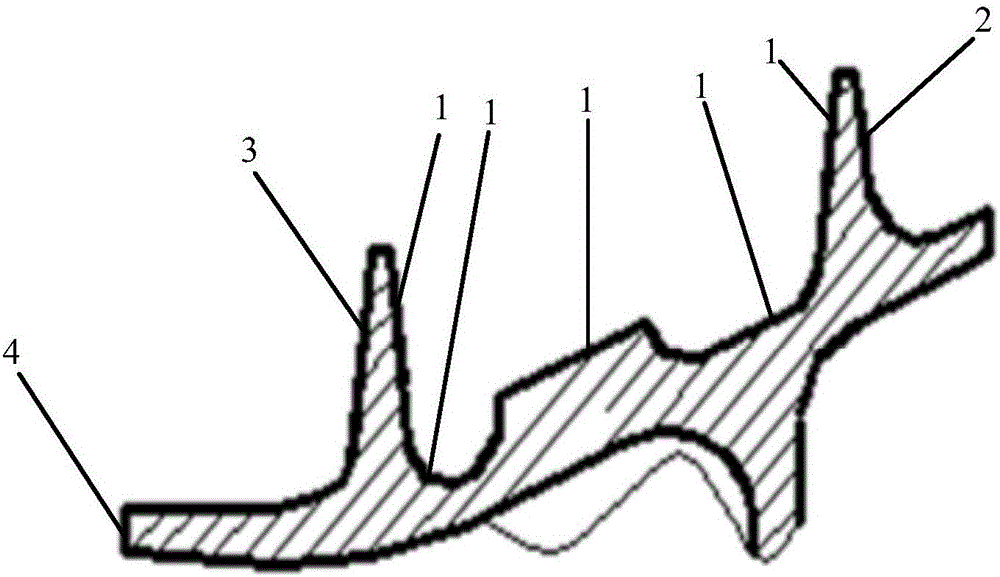

[0029] In order to solve the four processes of processing the crown of low-pressure turbine blades in the prior art, it is necessary to replace different rollers and grinding wheels, and to re-clamp the low-pressure turbine blades, which makes the low-pressure turbine blades unstable in size and low in processing efficiency. And because the thickness of the sealed tooth is thin, it is easy to produce burns and cracks in the process of processing the sealed tooth. The present invention provides a low-pressure turbine blade crown processing device and method, wherein the crown of the low-pressure turbine blade Processing equipment includes:

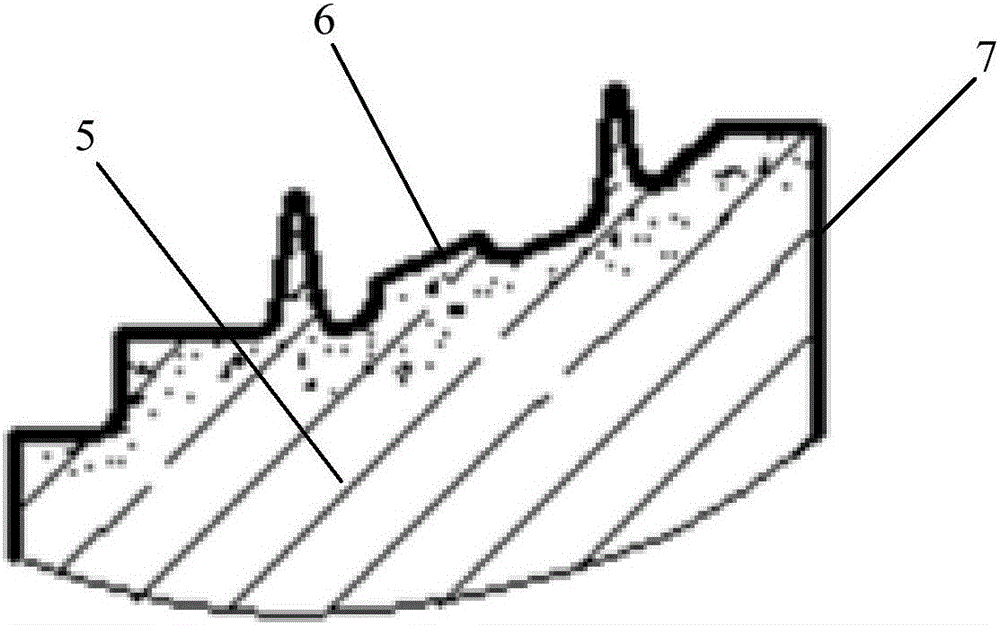

[0030] CNC single-sided creep grinder, roller 5, super soft grinding wheel 8 and fixture 9, CNC single-sided creep grinder is an existing grinder, for example, you can choose the model HZ-MKL-7140×10 CNC single-face creep Give grinder

[0031] The roller 5 is installed on the roller shaft of the dresser of the CNC single-sided slow-entry grinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com