A kind of ct19 mechanism spring dismounting device and using method

A technology of CT19 and energy storage spring, applied in the field of CT19 mechanism spring disassembly and assembly device, can solve the problems of difficult second installation, long operation time, danger of finger squeezing, etc., to achieve fast and convenient installation and fixation, and simple and convenient operation , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

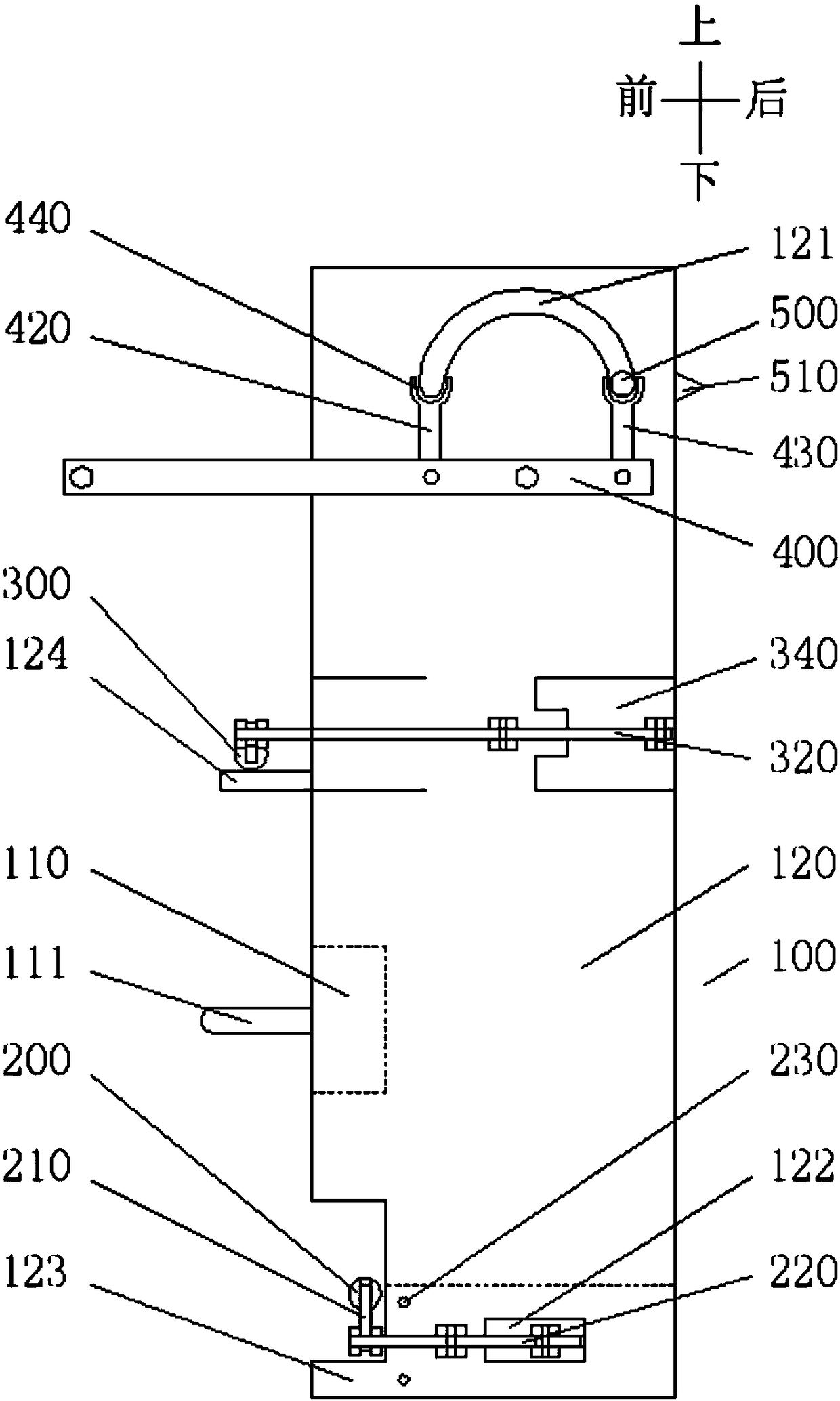

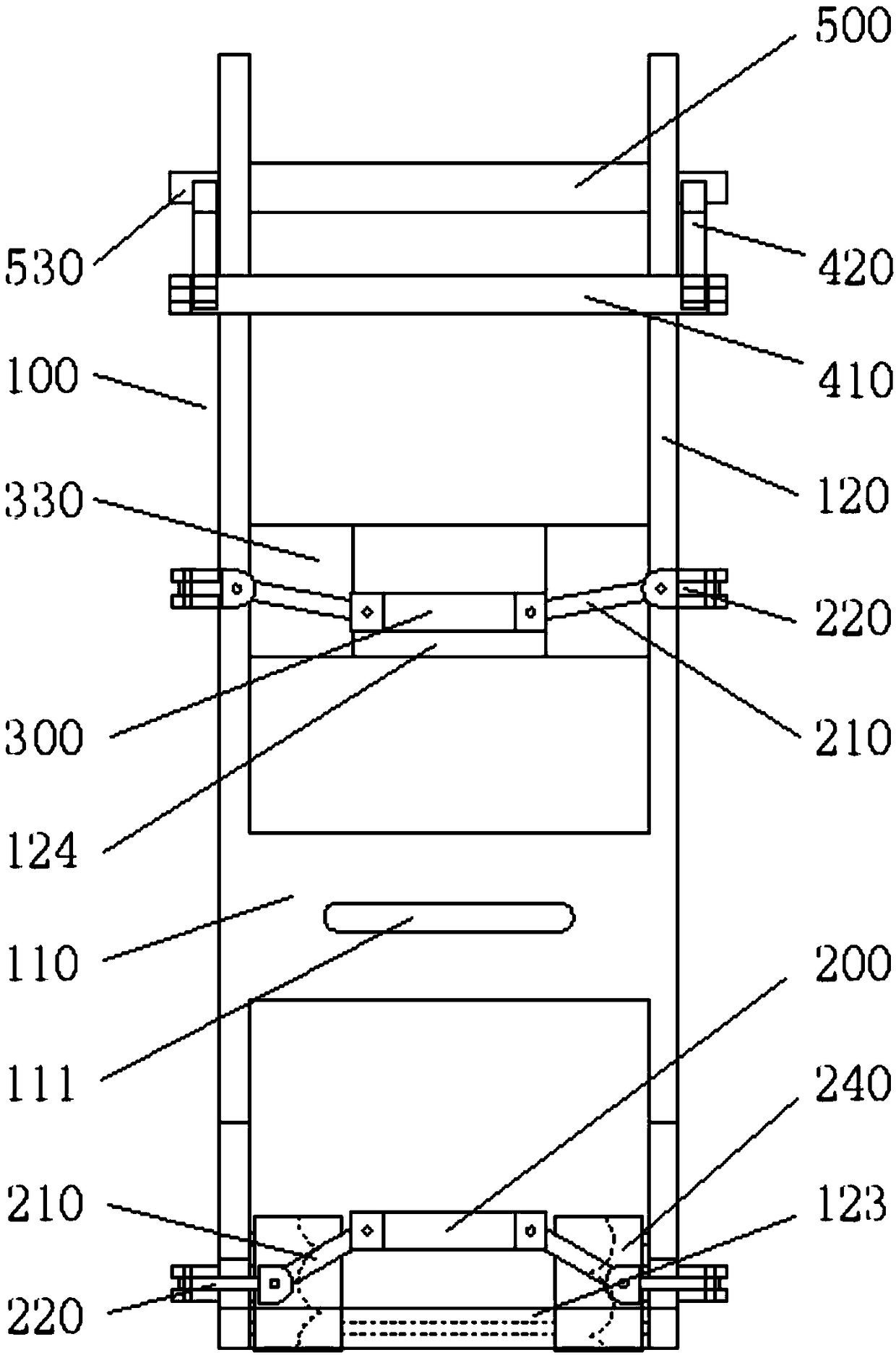

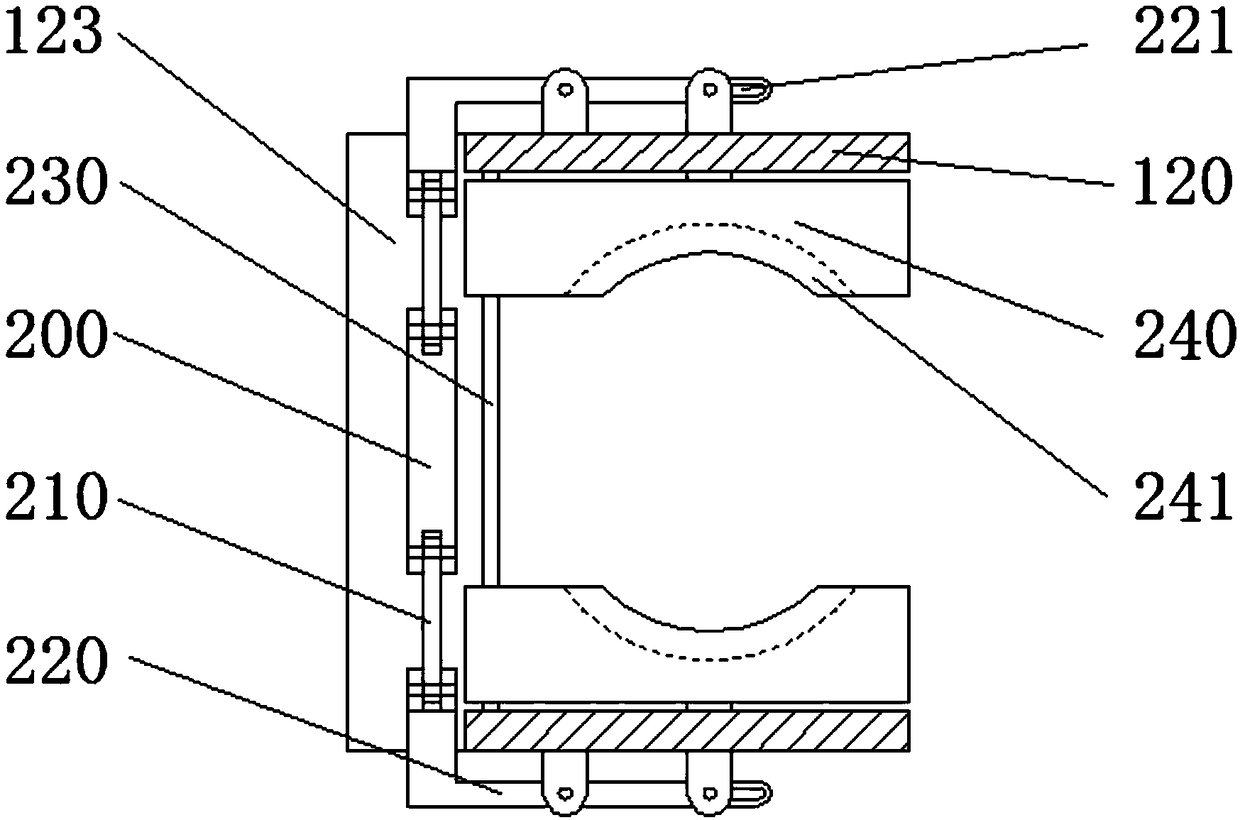

[0051] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0052] In addition, it should be noted that, unless otherwise specified or pointed out, the terms "first", "second", "third", "front", "rear", "left", "right" in the description may be involved ", "upper", "lower" and other descriptions are only used to distinguish the various components, elements, steps, etc. in the specification, not to express the logical relationship or sequence relationship between the various components, elements, and steps.

[0053] A CT19 mechanism spring dismounting device, including a bracket 100 with a panel 110 and side panels 120, the side panels 120 are arranged vertically and symmetrically on both sides of the panel 110, and a t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap