Grab separator and branch-leaf separating system and device

A separation device and separation equipment technology, applied in bark, wood processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, easy to cause hand injuries, etc., achieve high production efficiency and solve the effect of low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

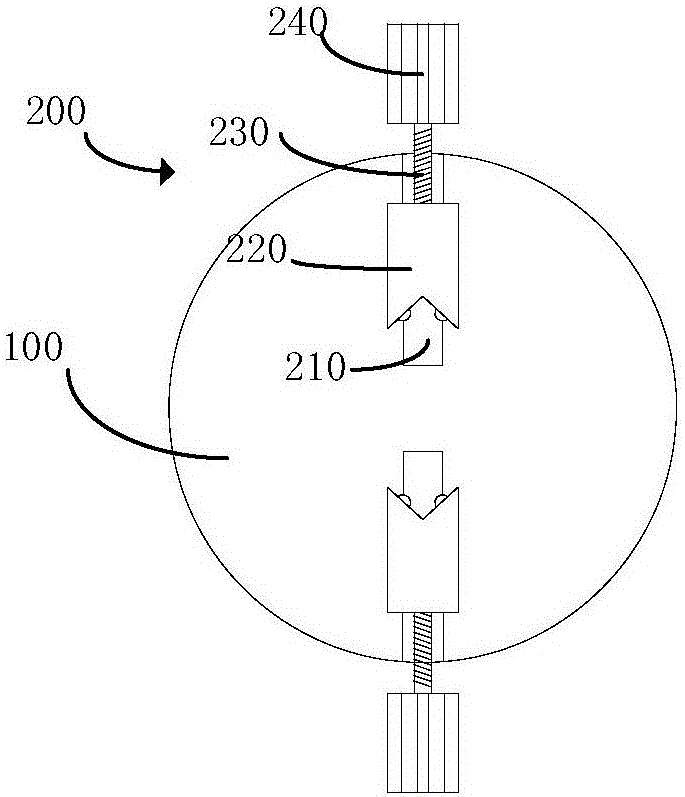

[0043] Please refer to figure 1 , the present embodiment provides a grasping and separating device 300, comprising a driving disc 100, two sliding mechanisms 200 arranged on the driving disc 100 and oppositely arranged, a branch channel is formed between the two sliding mechanisms 200, and the two sliding mechanisms 200 move toward each other to clamp the branches, and after clamping the branches, the drive disc 100 drives the two sliding mechanisms 200 to move along the length direction of the branches to complete the stripping of the tree stems and leaves.

[0044] The grasping and separating device 300 of this embodiment has a grasping function and a stripping function, specifically:

[0045]The two sliding mechanisms 200 move toward each other and clamp the branches, thereby realizing the grasping function of the grasping and separating device 300; after clamping the branches, the driving disc 100 drives the two sliding mechanisms 200 to move along the length direction of ...

Embodiment 2

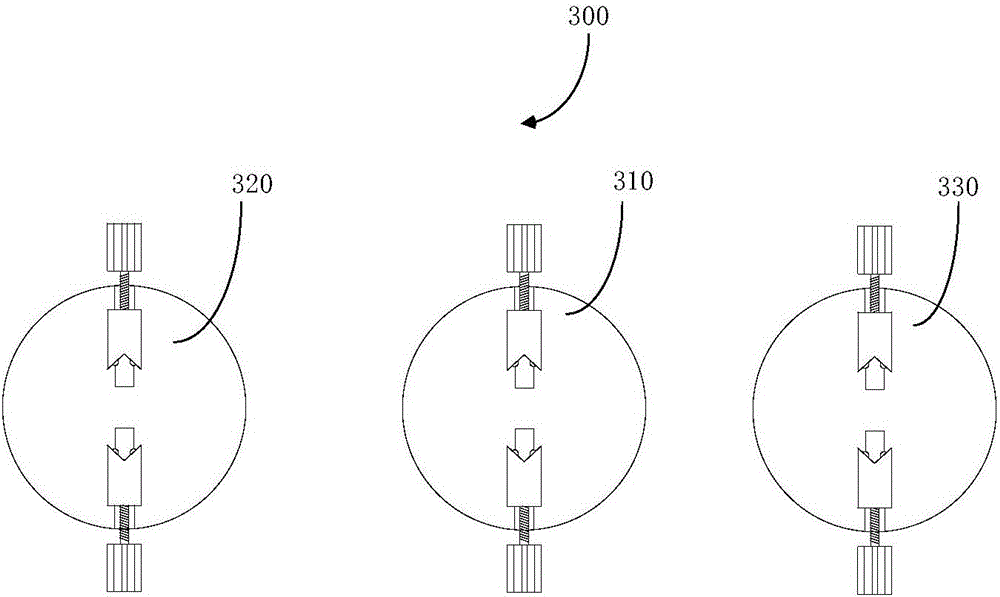

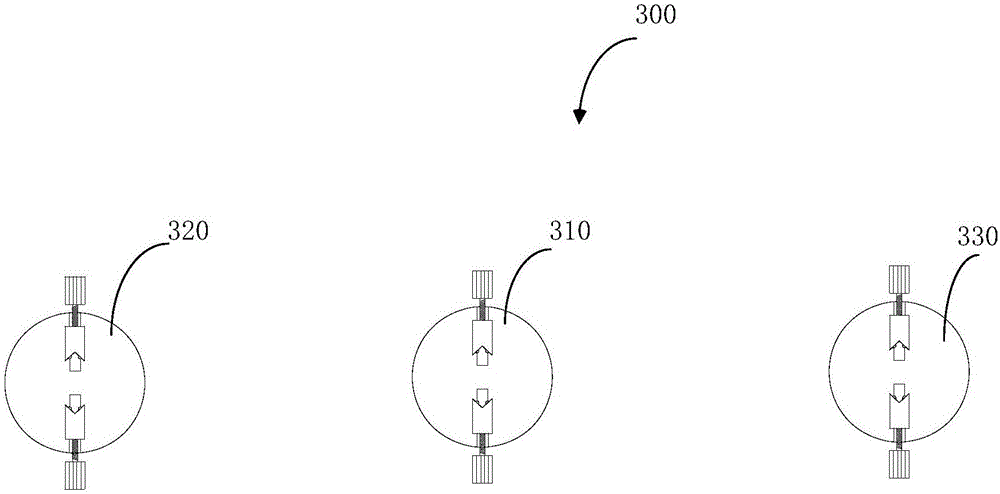

[0053] Please refer to figure 2 and image 3 , this embodiment provides a branch and leaf separation system including the grasping and separating device 300 in Embodiment 1, wherein the branch and leaf separating system includes: a middle grasping and separating device 310, left and right sides respectively located on both sides of the middle grasping and separating device 310 Side grabbing and separating device 320 and right grabbing and separating device 330;

[0054] The left grasping and separating device 320 has a first station and a second station. When the left grasping and separating device 320 is in the first station, the left grasping and separating device 320 clamps the branch and grasps and separates it away from the middle. Device 310 to peel off tree trunks and leaves until reaching the second station;

[0055] The right grabbing and separating device 330 has a third station and a fourth station. When the right grabbing and separating device 330 is in the thir...

Embodiment 3

[0059] Please refer to Figure 4 , this embodiment provides a branch and leaf separation device including the branch and leaf separation system in Embodiment 2, further comprising: a first transport mechanism 400, a second transport mechanism 500 arranged downstream of the first transport mechanism 400 along the material conveying direction, and A screening mechanism 600 arranged below the second transport mechanism 500;

[0060] The tree stems and leaves separated by the branch and leaf separation equipment fall into the first transportation mechanism 400, and are transported to the top of the second transportation mechanism 500 by the first transportation mechanism 400, and the separation of the tree stems and the leaves is completed at the second transportation mechanism 500, wherein , the tree trunk remains above the second transport mechanism 500 , and the leaves are screened by the screening mechanism 600 after passing through the second transport mechanism 500 .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com