An energy-saving electric punch and its working method

A working method and punch technology, which can be used in punching machines, manufacturing tools, presses, etc., can solve problems such as power waste, and achieve the effects of compact structure, remarkable energy saving effect and high stability in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

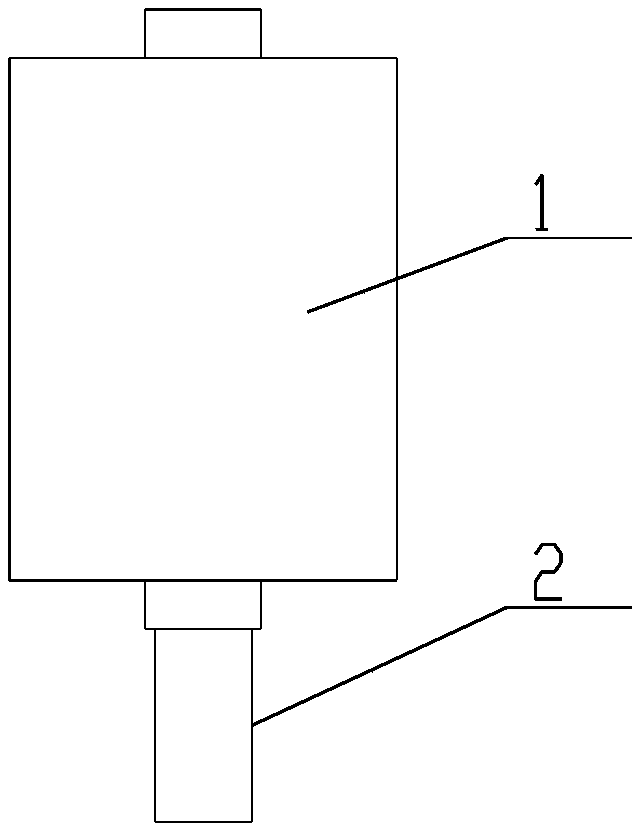

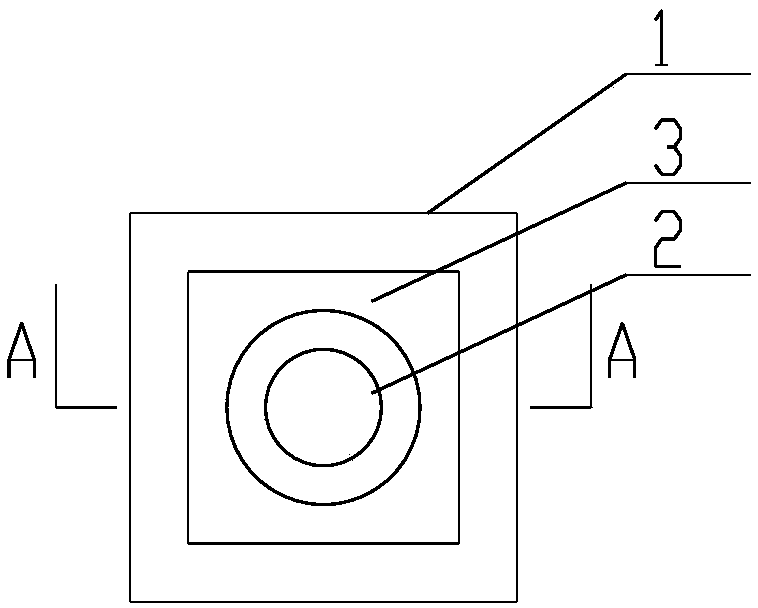

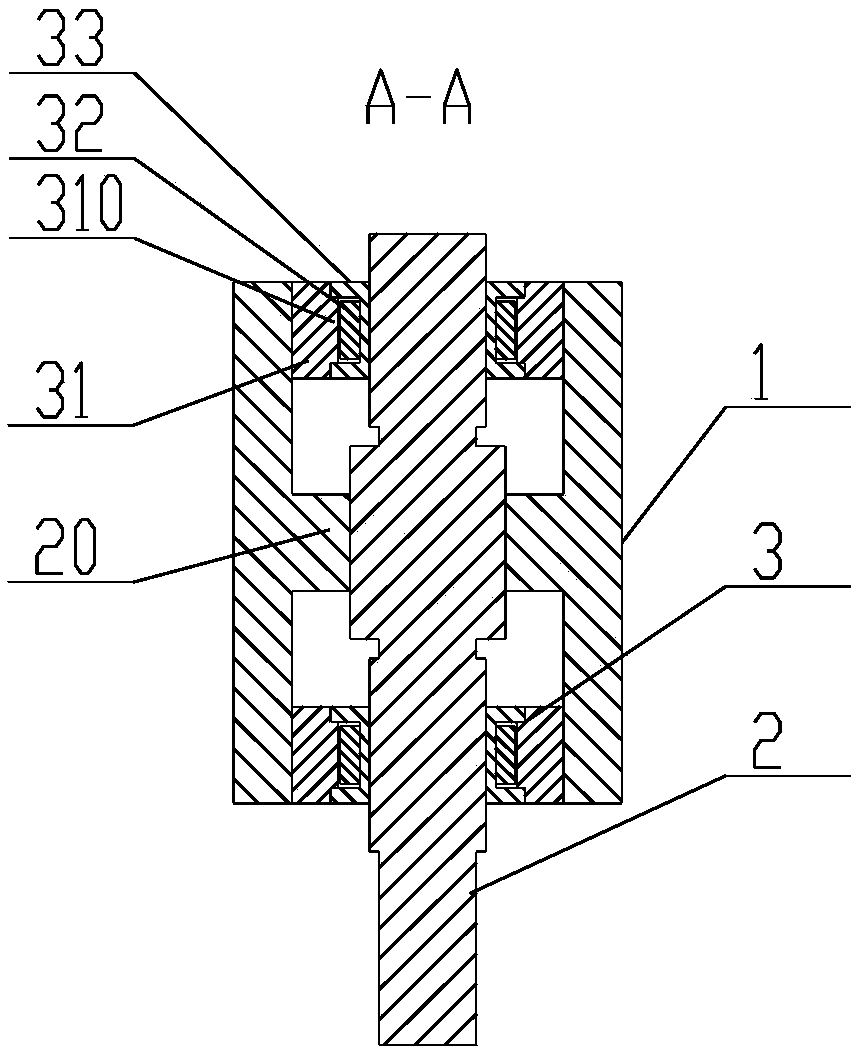

[0023] The present invention as Figure 1-7 As shown, it includes a fixed seat 1, a screw 2, a punch and a pair of drive assemblies 3, the punch is fixedly connected to the end of the screw, the screw 2 is passed through the fixed seat 1, and the screw 2 is provided with There is a guide block 20 arranged along its axial direction, the fixed seat 1 is hollow, and its inner wall is provided with a guide ring adapted to the guide block 20 along the axial direction; so that a moving pair is formed between the guide block and the guide ring ( Can only move axially, not rotate)

[0024] The surface of the screw rod 2 is provided with two sections of external threads, and the pitches can be different or equal;

[0025] The two drive assemblies 3 are connected in the fixed seat 1 and respectively sleeved on the two external threads. The drive assembly includes a stator 31, a rotor 32 and a nut 33, and the stator 31 is fixedly connected to the fixed seat 1. On the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com