Wing deformation structure of water and air amphibious aircraft

A deformable structure and aircraft technology, applied in the field of aircraft wings, can solve problems such as poor handling and maneuvering performance, poor aerodynamic performance, and reduce radar reflection signals, so as to improve the handling and maneuvering performance, improve flight speed, Reduces flight resistance and the effect of radar transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

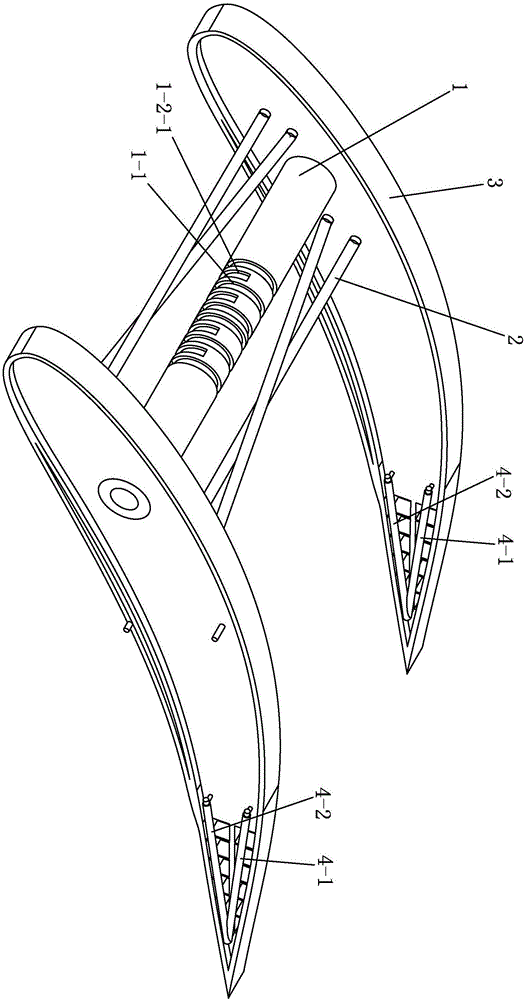

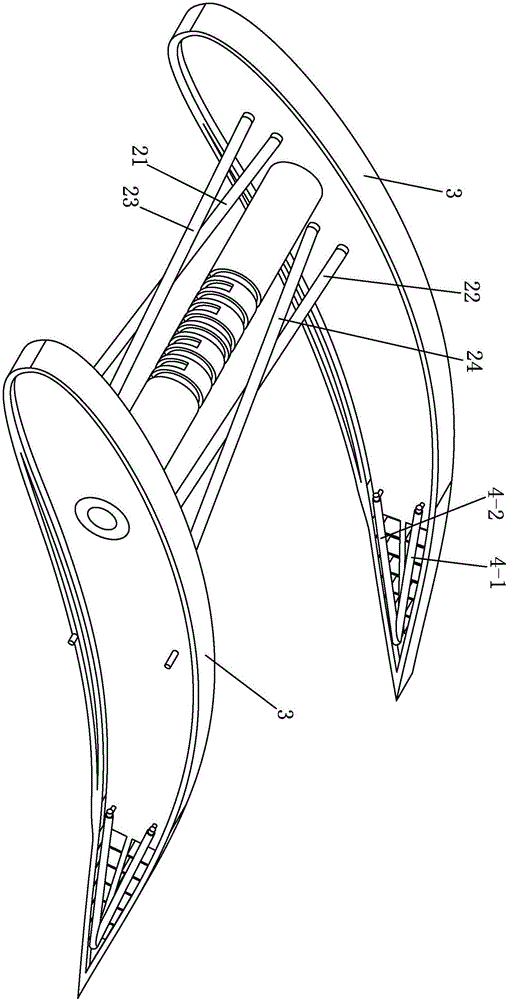

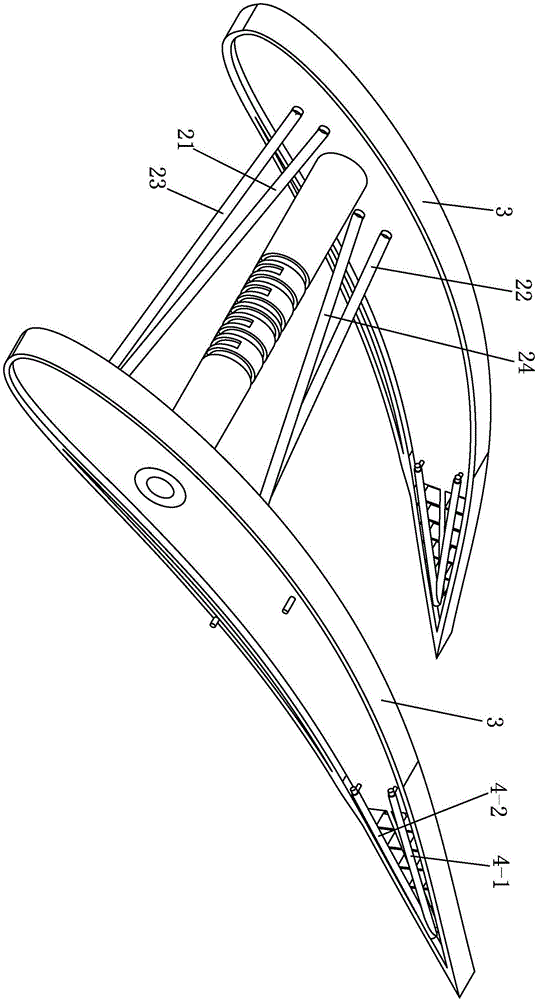

[0017] see figure 1 Explain that a wing deformation mechanism of a water-air amphibious aircraft includes a variable stiffness spar 1, two bending torsion deformation components and two wing ribs 3;

[0018] Each bending torsion deformation assembly includes two aerodynamic muscle drivers 2, and the two aerodynamic muscle drivers 2 of each bending torsion deformation assembly are arranged crosswise; the two wing ribs 3 are prefabricated wing shape structures, and the two A variable stiffness spar 1 and two bending torsion deformation assemblies are arranged between the wing ribs 3; the two bending torsion deformation assemblies are arranged on both sides of the variable stiffness spar 1; each of the aerodynamic muscle drivers 2 The two ends of each are respectively connected with the two wing ribs 3;

[0019] The va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com