A muddy water shield fully automatic pipe changing crane

A mud-water shield, fully automatic technology, applied in the direction of cranes, traveling mechanisms, load hanging components, etc., can solve the problems of low degree of automation, low safety factor and low work efficiency, and achieve reduced labor intensity, simple structure, and safe operation. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

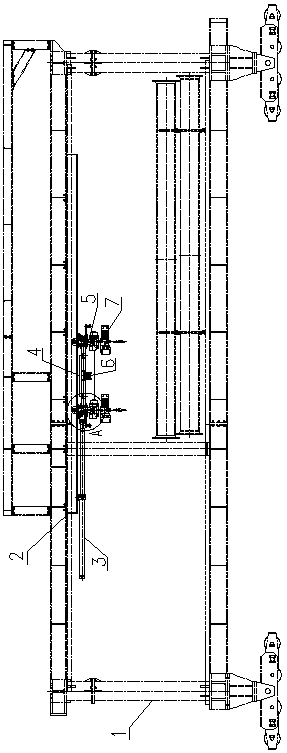

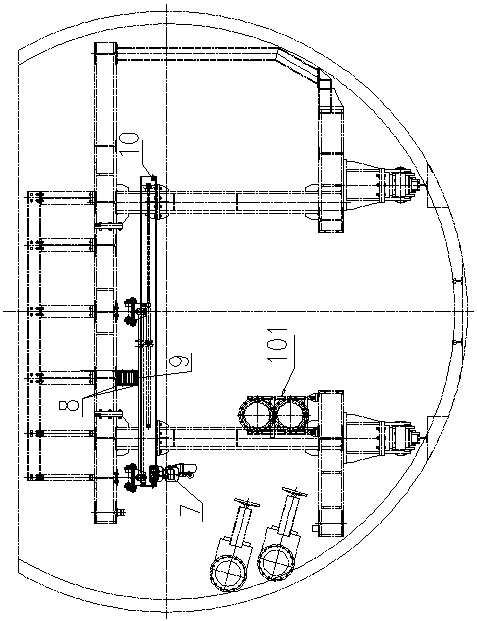

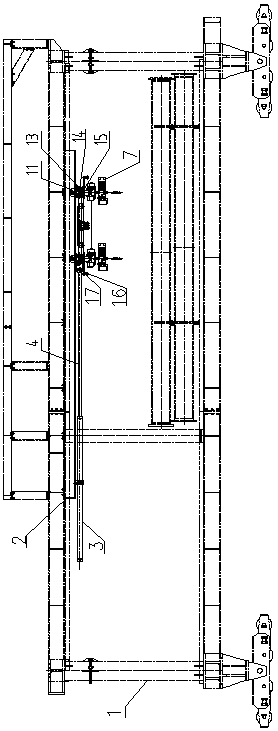

[0022] Embodiment 1: as Figure 1-8 As shown, a mud-water shield automatic pipe changing crane includes a trailer 1 and a pipe changing crane mechanism. The pipe changing crane mechanism is installed on the trailer. The trailer 1 is provided with a storage pipe mechanism 101 for storing mud pipes. Wherein, the pipe changing crane mechanism includes a pipe changing crane longitudinal beam 2 fixedly connected with the trailer 1, the pipe changing crane longitudinal beam 2 is provided with a longitudinal translation oil cylinder 3, and the telescopic end of the longitudinal translation oil cylinder 3 is connected with a walking frame 4 , the longitudinal translation oil cylinder pushes the traveling frame to move along the longitudinal beam of the pipe changing crane, the traveling frame 4 is provided with a crane beam frame 5 and a horizontal translation oil cylinder 6, the crane beam frame is located below the pipe changing crane longitudinal beam, and the horizontal translation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com