A multifunctional load simulation test bench

A technology of load simulation and test bench, which is applied in the testing of machine/structural components, measuring devices, instruments, etc., which can solve the problem of failure to consider the comfort of installation, disassembly, and replacement of test personnel, the stress of the main body of the test bench, and the inability to Accurately realize the load dynamic simulation and other problems, achieve the effect of convenient processing, production and disassembly, avoid unbalanced radial force, and obvious cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

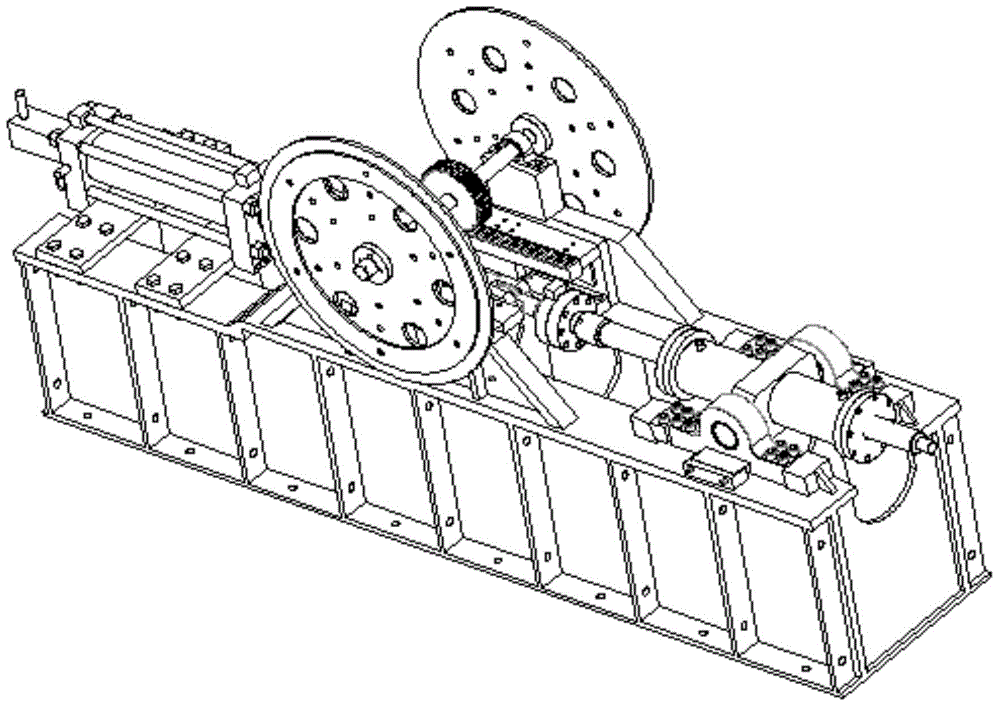

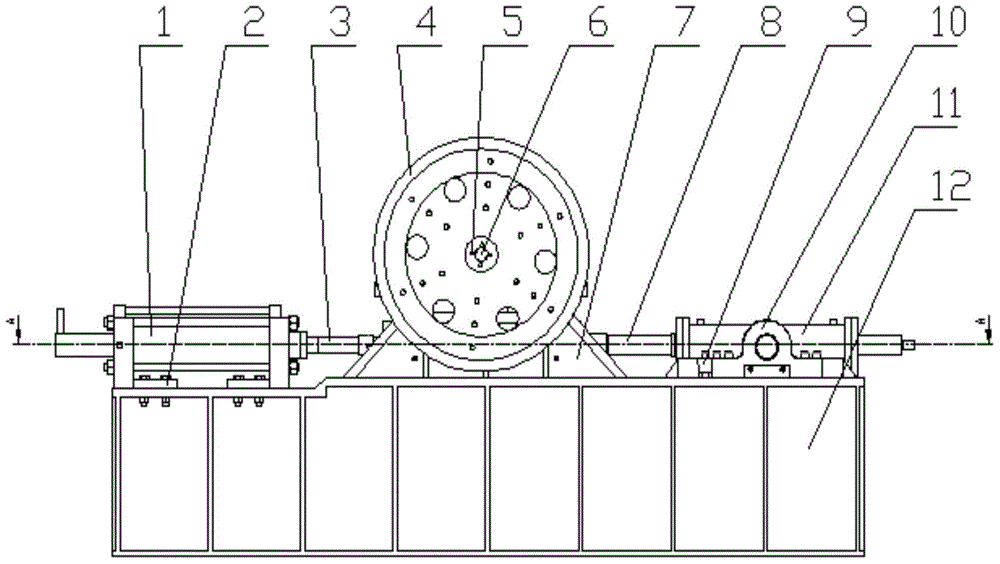

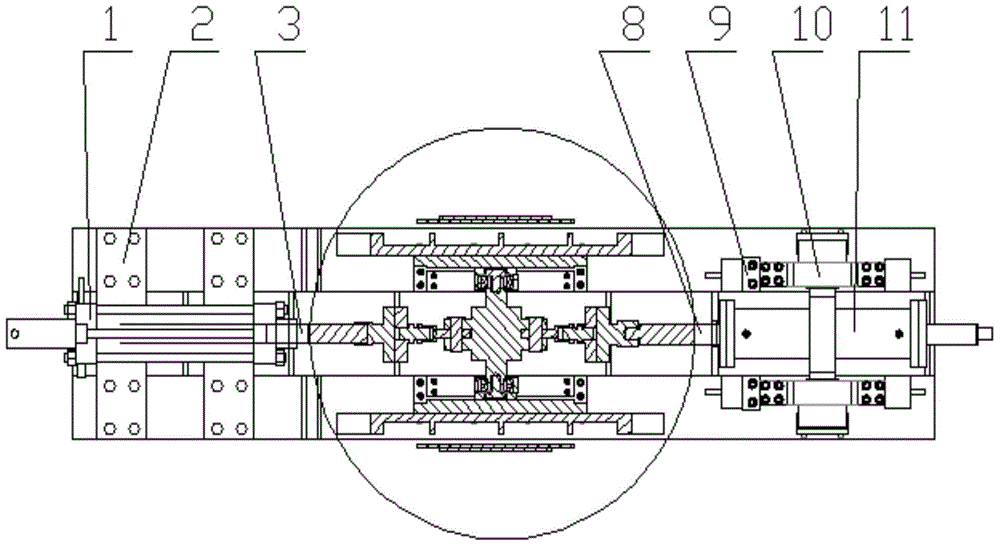

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0053] refer to figure 1 , the present invention is a multifunctional load simulation test bench, which includes a base 12, a loading steering gear 11, a loading steering gear fixing ear seat 10, a loading steering gear front and rear position adjustment wedge 9, a loading steering gear left and right position adjustment block 33, Pull pressure sensors 22, 14, connecting flanges 21, 13, output shaft 8 of the loading steering gear, intermediate inertia block 18, earring shaft 16 of the steering gear under test, 1 steering gear under test, mounting plate 2 of the steering gear under test, rack 31. Gear 27, gear shaft 28, gear shaft support 29, rolling bearing 25, intermediate support 7, inertia disk 4, anti-rotation "cross" frame 5, threaded plug 6 and anti-lateral force guide wheel 26, adapter 15,23, pins 17,19, guide wheel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com