A Mechanical Bending Plate Slope Adjusting Fixture and Method

A technology of slope adjustment and fixture, which is applied in the direction of metal processing machinery parts, manufacturing tools, clamping, etc., can solve the problems of low adjustment positioning accuracy, time-consuming and labor-intensive manual operation, and poor processing quality of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

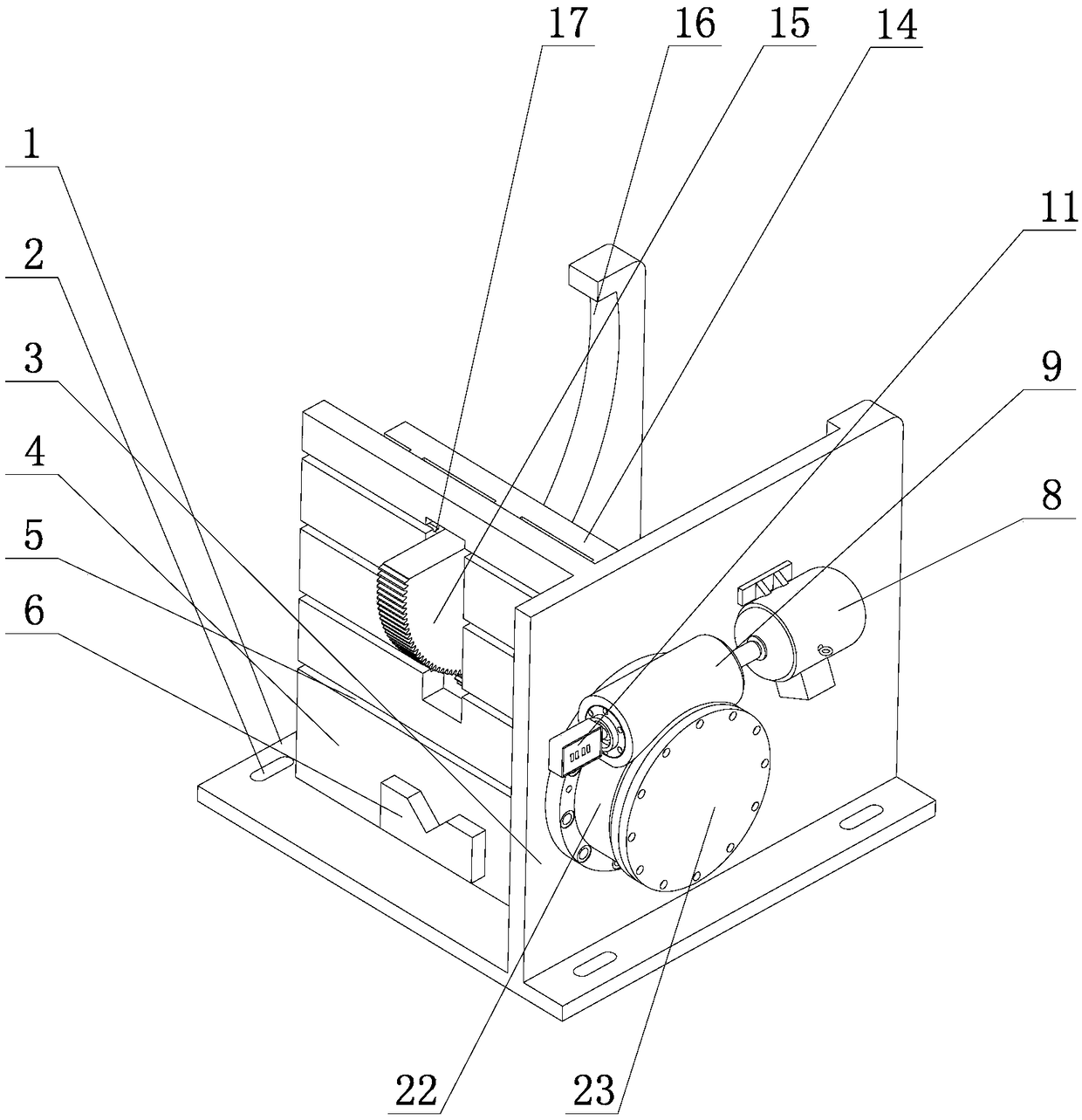

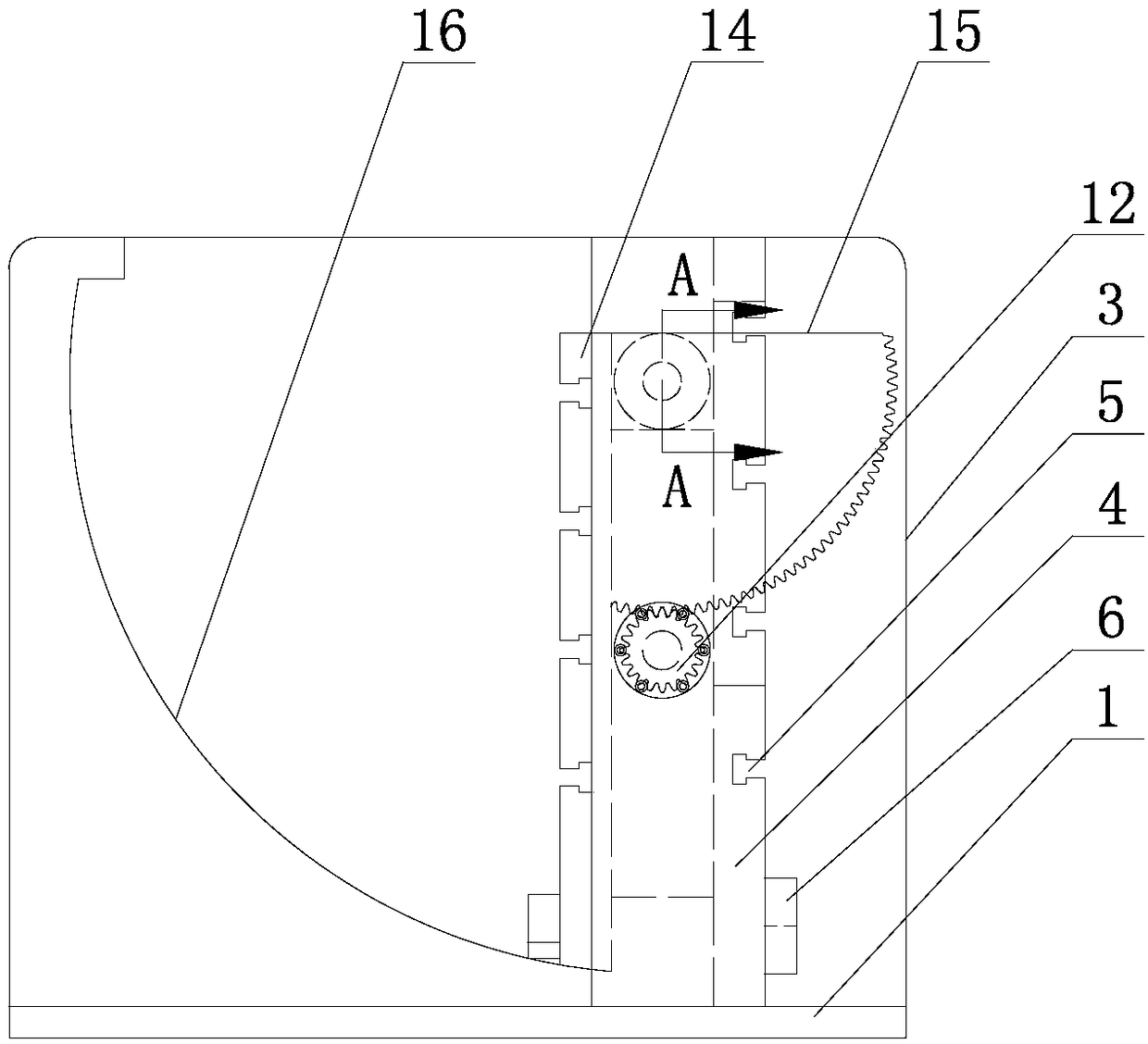

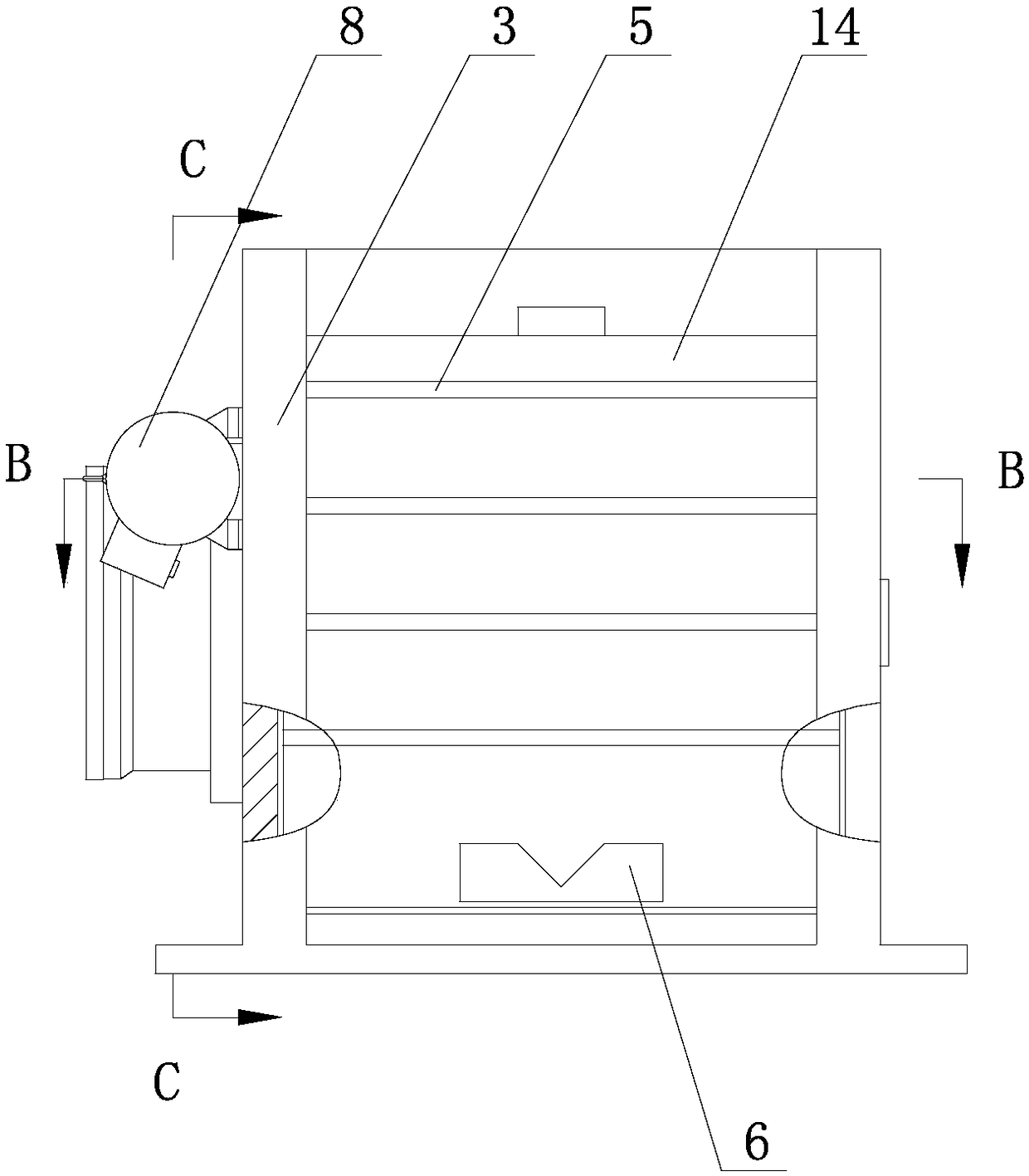

[0032] In order to clearly illustrate the technical characteristics of this solution, the following describes the present invention in detail through specific implementations and in conjunction with the accompanying drawings.

[0033] Such as Figure 1-9 As shown, a mechanical bending plate type tilt adjustment fixture includes a fixture base 1. The fixture base 1 is provided with slots 2 at four corners, and the fixture base 1 is provided with side vertical plates 3 and a middle The vertical board 4, the middle vertical board 4 is provided with a number of T-shaped grooves 5 spaced from top to bottom on the outer surface, the middle vertical board 4 is provided with a V-shaped positioning block 6 at the bottom, and the middle vertical board 4 is horizontally spaced with two The protruding bracket 7, the side vertical plate 3 is provided with a servo motor 8 on the outer surface, the servo motor 8 is connected with the worm 9, the worm 9 is connected with the worm wheel 10, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com