A sewage treatment tank and treatment process

A sewage treatment tank and process technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sedimentation treatment, etc., can solve the problems of reduced denitrification effect, narrow scope, high requirements, etc. The effect of automatic adjustment of sludge rate and oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

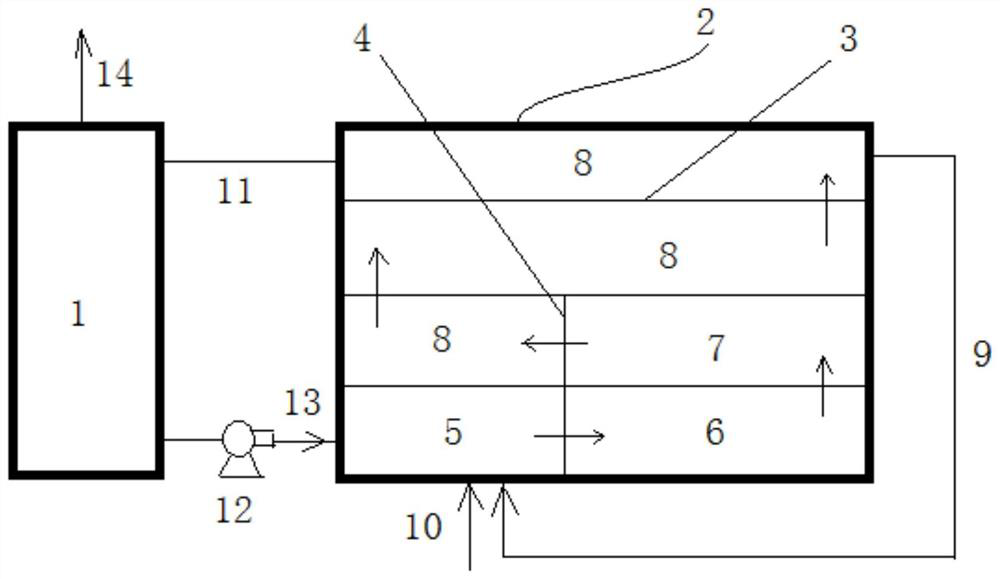

[0026] A kind of sewage treatment tank and treatment process, its structure and schematic flow chart are as shown in the figure, the treatment tank includes a sedimentation tank 1 and a degradation tank 2, the degradation tank 2 is a pool body surrounded by pool walls and a partition arranged in parallel in the pool body The partition wall 3 separates the pool body to form a serpentine fluid passage, and then sets a partition wall 4 perpendicular to the partition wall 3 in the fluid passage, and divides the fluid passage into an adjustment area 5 and an anoxic area 6 in turn. , anaerobic zone 7 and aerobic zone 8; regulating zone 5 and aerobic zone 8 are communicated with sedimentation tank 1 respectively, regulating zone 5 is provided with sewage inlet pipe, and the middle part of aerobic zone 8 is communicated with regulating zone 5 through return pipe. Pass the raw sewage 10 into the regulating area 5, mix it with the reflux liquid 9 from the aerobic area 8, and then connect...

Embodiment 2

[0039] Adopt the process similar to embodiment 1, difference is:

[0040] (1) The length ratio of regulation zone, anoxic zone, anaerobic zone and aerobic zone is 0.8:1:1:6;

[0041] (2) The internal backflow is 1:1;

[0042] (3) The external backflow is 0.8:1.

[0043] After testing, the denitrification rate of this embodiment is 79.6%, which is higher than that of Comparative Example 1.

Embodiment 3

[0045] Adopt the process similar to embodiment 1, difference is:

[0046] (1) The length ratio of regulation zone, anoxic zone, anaerobic zone and aerobic zone is 1.2:1:1:4.5;

[0047] (2) The internal backflow is 2:1;

[0048] (3) The external return flow is 1.2:1.

[0049] After testing, the denitrification rate of this embodiment is 80.2%, which is higher than that of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com