Damage-resistance high-performance washing-machine water-level sensor

A water level sensor and washing machine technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of hidden quality problems in product quality, increase in the volume of water level sensors, and limit the scope of application, so as to simplify the assembly operation process, Simple and reliable structure and the effect of reducing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

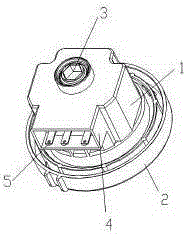

[0016] Example 1. An anti-damage high-performance washing machine water level sensor, including an air cover 2, a coil frame and a bracket 1, a screw hole 31 is arranged on the top wall of the bracket 1, an adjusting nut 3 is installed in the screw hole 31, and an air nozzle is arranged at the bottom center of the air cover 2 21. It is characterized in that: the water level sensor is not provided with an adjustment cylinder, the adjustment nut 3 is directly arranged on the top wall of the bracket 1, the bracket 1 is a barrel-shaped structure with an opening at the bottom, and a mounting Flange 11, the mounting flange 11 extends outward from the outer wall of the bracket 1 along the radial direction of the bracket 1; the gas cover 2 engages with the mounting flange 11 set on the bottom of the bracket 1 through the staple 22 set on the inner wall of the top fixed. This solution directly engages and fixes the bracket 1 and the gas cover 2 by setting the flange 11 on the bracket ...

Embodiment 2

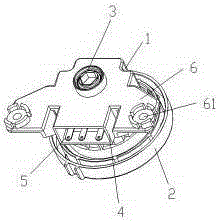

[0019] Example 2. An anti-damage high-performance washing machine water level sensor, including an air cover 2, a coil frame and a bracket 1, a screw hole 31 is arranged on the top wall of the bracket 1, an adjusting nut 3 is installed in the screw hole 31, and an air nozzle is arranged at the bottom center of the air cover 2 21. It is characterized in that: the water level sensor is not provided with an adjustment cylinder, the adjustment nut 3 is directly arranged on the top wall of the bracket 1, the bracket 1 is a barrel-shaped structure with an opening at the bottom, and a mounting Flange 11, the mounting flange 11 extends outward from the outer wall of the bracket 1 along the radial direction of the bracket 1; the gas cover 2 engages with the mounting flange 11 set on the bottom of the bracket 1 through the staple 22 set on the inner wall of the top fixed. This solution directly engages and fixes the bracket 1 and the gas cover 2 by setting the flange 11 on the bracket ...

Embodiment 3

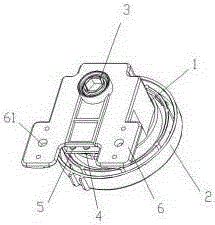

[0023] Example 3. An anti-damage high-performance washing machine water level sensor, including an air cover 2, a coil frame and a bracket 1, a screw hole 31 is arranged on the top wall of the bracket 1, an adjusting nut 3 is installed in the screw hole 31, and an air nozzle is arranged at the bottom center of the air cover 2 21. It is characterized in that: the water level sensor is not provided with an adjustment cylinder, the adjustment nut 3 is directly arranged on the top wall of the bracket 1, the bracket 1 is a barrel-shaped structure with an opening at the bottom, and a mounting Flange 11, the mounting flange 11 extends outward from the outer wall of the bracket 1 along the radial direction of the bracket 1; the gas cover 2 engages with the mounting flange 11 set on the bottom of the bracket 1 through the staple 22 set on the inner wall of the top fixed. This solution directly engages and fixes the bracket 1 and the gas cover 2 by setting the flange 11 on the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com