Vertically-pivoted folded movable bridge and using method

A technology of vertical rotation and folding mechanism, which is applied to the opening bridge. In the field of bridge deck, it can solve the problems of bridge deck elevation change, restricted navigation height, poor adaptability to water level changes, etc., and achieve the effect of reducing bridge tower height, reducing energy consumption, and improving simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

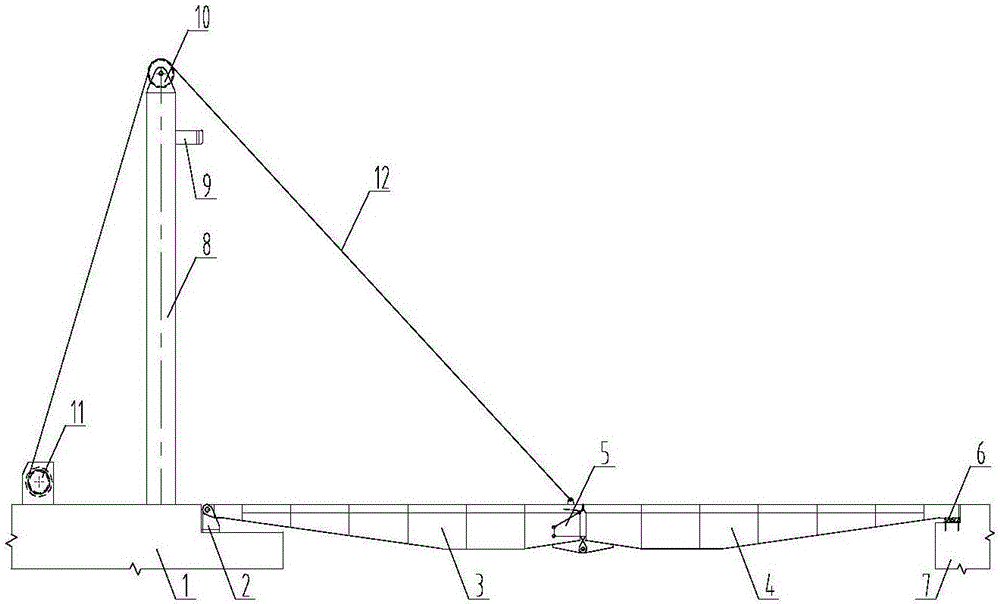

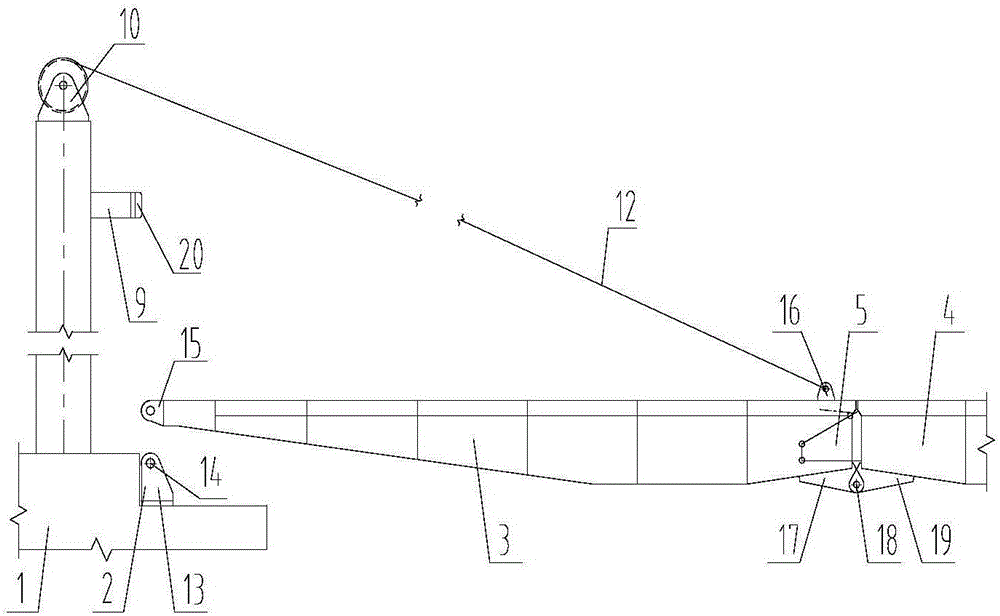

[0016] Embodiment 1: see attached figure 1 , 2 , a vertically rotating folding and opening bridge, which includes: left abutment 1, left support 2, left half span 3, right half span 4, folding mechanism 5, right support 6, right abutment 7, bridge Tower 8, locking device 9, tower top pulley 10, winch 11, wire rope 12, hydraulic system and electrical system;

[0017] The left support 2 is symmetrically arranged on the steps on both sides of the left abutment 1 along the bridge axis, the bridge tower 8 is arranged on the upper surface of the left abutment 1, and the locking device 9 is installed on the upper right side of the bridge tower 8 for locking the left half The bridge span 3 and the bridge tower 8 are unlocked / locked; the tower top pulley 10 is installed on the top of the bridge tower 8, the winch 11 is installed on the ground on the left side of the bridge tower 8, and the right support 6 is arranged symmetrically on the right abutment 7 along the bridge axis. On the...

Embodiment 2

[0021] Embodiment 2: see attached Figure 3-10 , the method of using the vertically rotating folding and opening bridge, including the following steps:

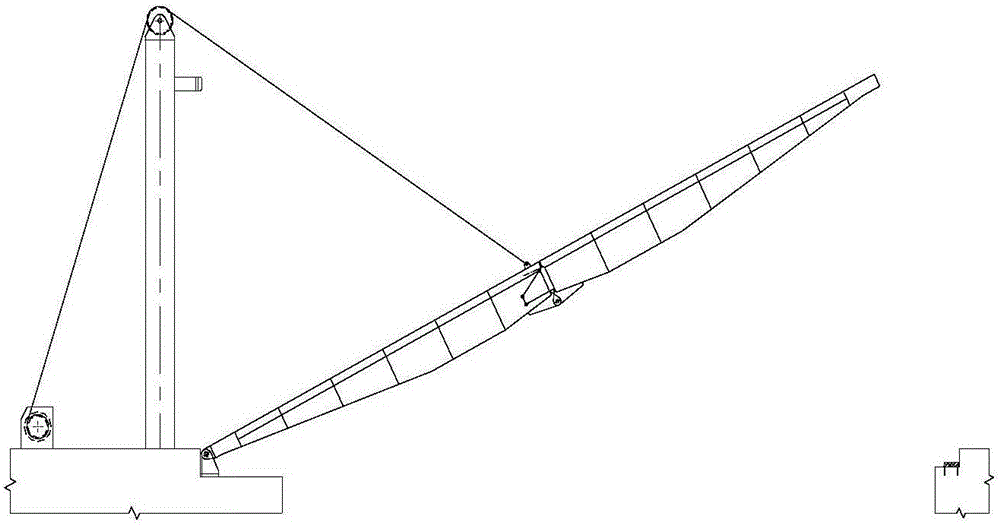

[0022] A. Bridge opening, see appendix Figure 3-6

[0023] The wire rope 12 is received by the winch 11, so that the left half span 3, the right half span 4 and the folding mechanism 5 rotate up with the left support 2 as the fulcrum, when the left half span 3 rotates to form an angle of 20-30° with the ground , while receiving the wire rope 12 by the winch 11, the right half span 4 is driven by the folding mechanism 5 to rotate clockwise with the connecting pin 13 as the fulcrum, so as to realize the folding of the left half span 3 and the right half span 4, when the left half span When 3 and the right half span 4 are folded into an angle of 10-20°, the folding mechanism 5 is closed to stop the folding action, and the winch 11 continues to receive the wire rope 12 until the left half span 3 is in a vertical state and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com