Structure heat preservation integrated assembling type box structure system and construction method thereof

A box-type structure and structural thermal insulation technology, applied in thermal insulation, building thermal insulation materials, building components, etc., can solve the problems of structural joints that cannot guarantee sealing, low energy-saving efficiency, single function, etc., to achieve rich patterns and improve energy-saving efficiency. , the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

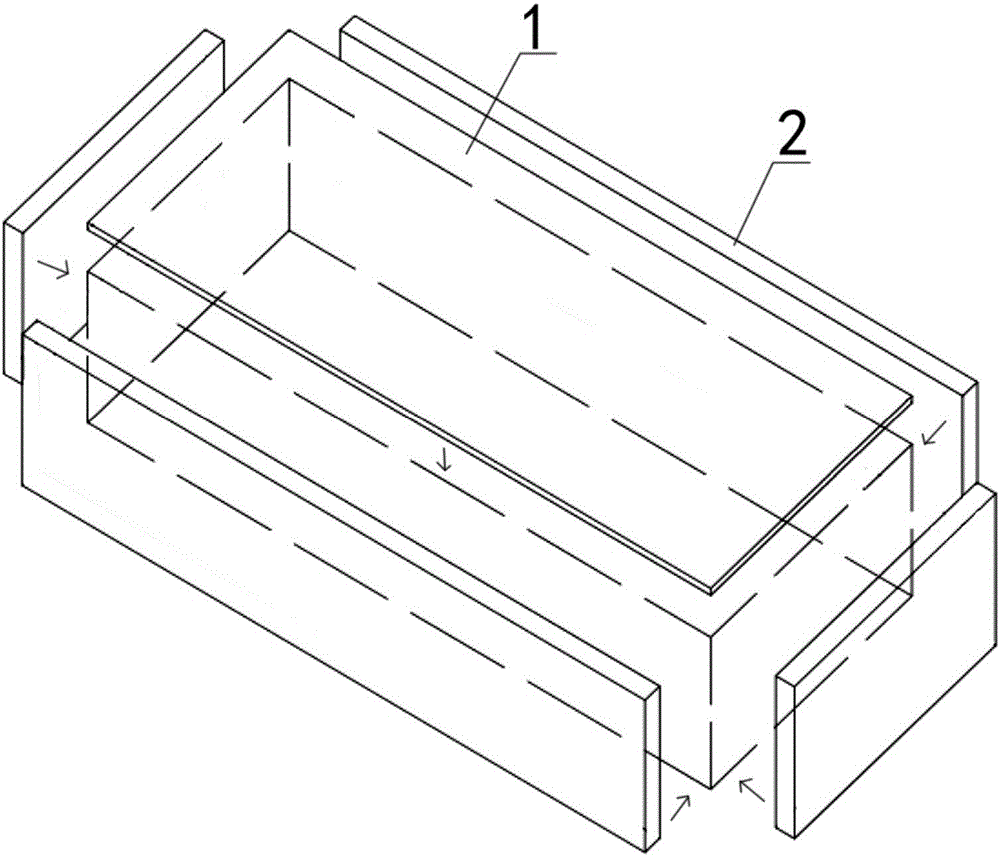

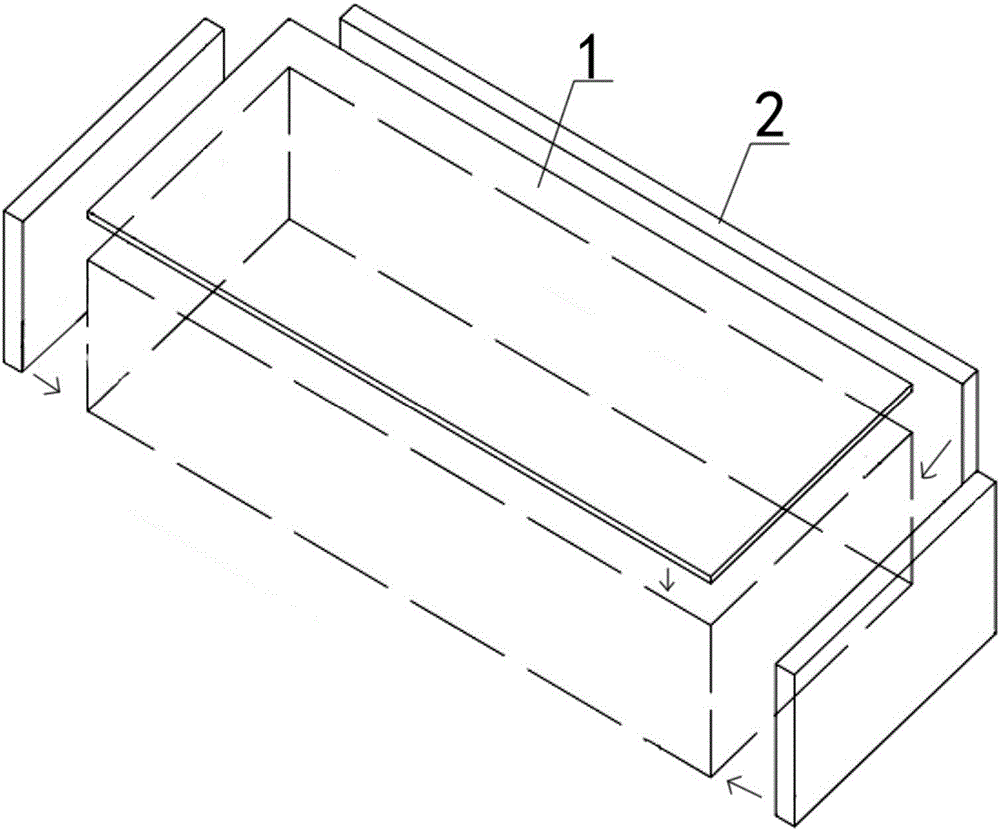

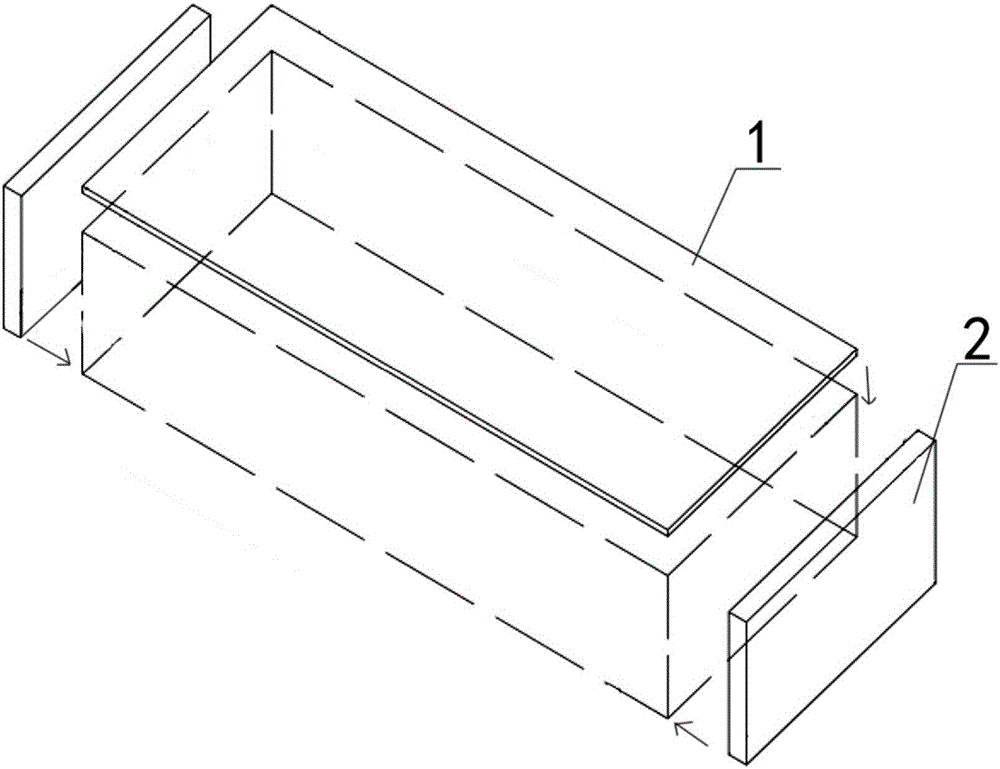

[0054] Embodiment one sees Figure 7a-7b As shown, this prefabricated box-type structure system with integrated structural insulation includes a single-layer structure formed horizontally by a bell-shaped five-sided box-type structural unit and two bell-shaped single-wall box-type structural units, of which 2 All of the bell jars lacking a single wall box structure unit are bell jars lacking a single wall box structure unit. The splicing between box-type structural units includes horizontal splicing between box-type structural units on the same layer, and the sum of the number of wall components 2 on the splicing side between two box-type structural units is not more than one side in total.

[0055] see Figure 8 As shown, the same kind of components include adjacent roof and floor components on the same floor, and the left and right end faces of the adjacent roof and floor components on the splicing side are respectively provided with matching floor tenon 5 and floor mortise...

Embodiment 2

[0057] Embodiment two see Figures 10a-10b As shown, the difference from Example 1 is that this assembled box-type structural system with integrated structure and heat preservation includes two bell-type five-sided box-type structural units and four bell-type box-type structural units without walls. Single layer double row structure. Among them, the two box-type structural units with a single wall in the bell jar are box-type structural units with a single wall in the bell jar, and the box-shaped structural units with a single wall in the bell jar are both box-type structural units with double walls in the bell jar. The two wall elements in the Bellless Double Wall Cassette unit are located adjacent to each other.

Embodiment 3

[0058] Embodiment three see Figures 11a-11b As shown, this assembled box-type structural system with integrated structure and heat preservation includes a double-layer structure formed by two bell-shaped five-sided box-type structural units. The splicing between the cassette structural units includes vertical splicing between the upper and lower cassette structural units.

[0059] see Figure 12 As shown, the similar components are adjacent wall components on the upper and lower floors, and the upper and lower end faces of the adjacent wall components are provided with the upper and lower splicing tenon 15 and the upper and lower splicing mortise on the wall. 16. In this embodiment, the outer walls 3 of different layers are adjacent. The upper and lower splicing tenons 15 on the wall are arranged on the lower box-type structural unit, and the upper and lower splicing sockets 16 on the wall are arranged on the upper box-like structural unit. Note that the upper and lower sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com