Ceiling radiant tube structure embedded under reinforcing steel bars and construction method of ceiling radiant tube structure

A construction method and radiant tube technology, applied in building structure, building components, heating methods, etc., can solve problems such as difficult maintenance, high cost, and low thermal efficiency utilization rate of heat insulation and constant temperature schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

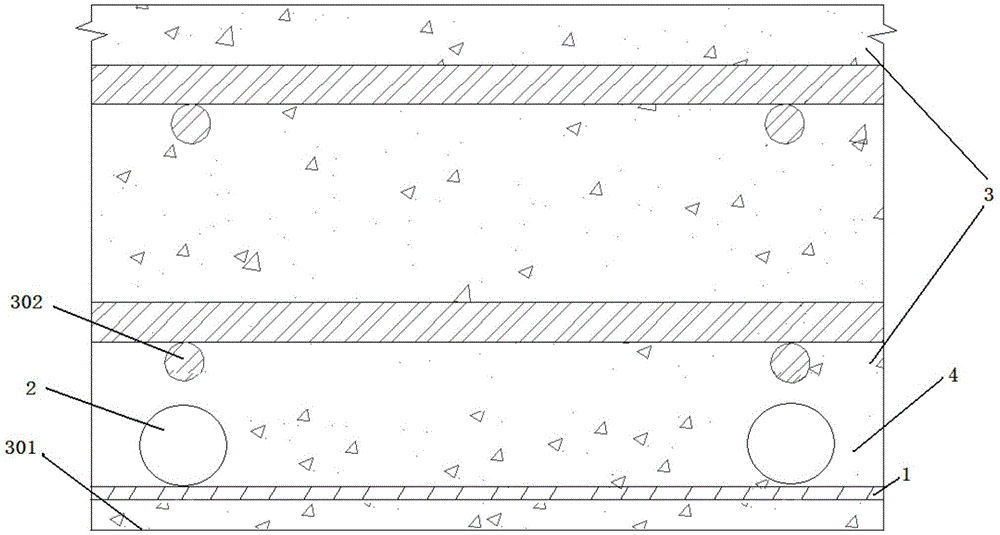

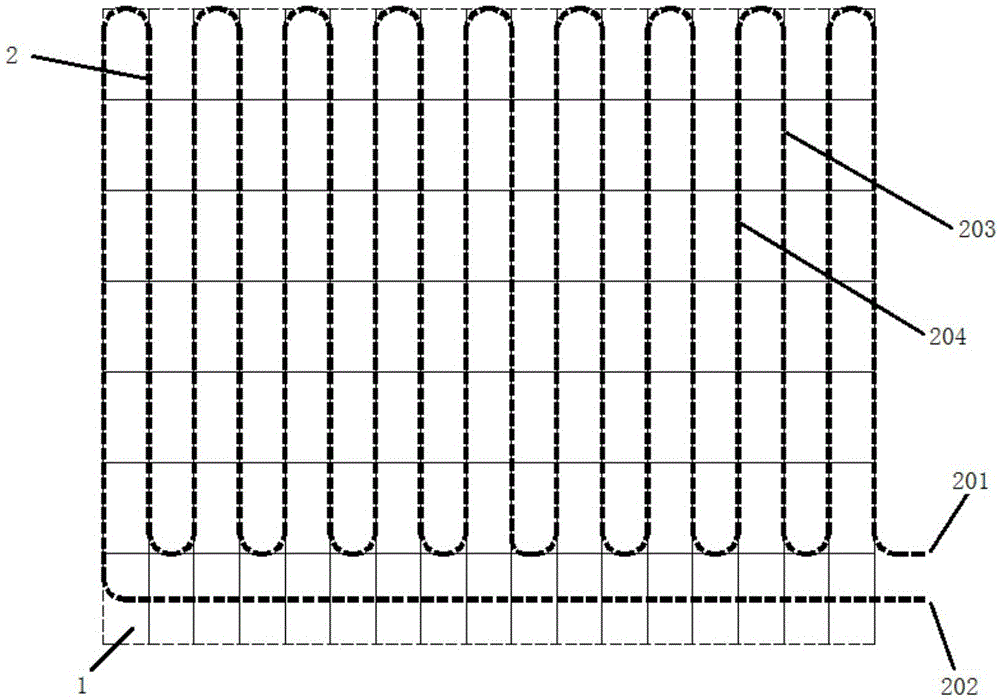

[0042] refer to figure 1 , shows a schematic structural view of a ceiling radiant tube structure based on buried steel bars in Embodiment 1 of the present invention. In this embodiment, the structure of the ceiling radiant tube based on buried steel bars may include: a steel mesh sheet 1 , an "S"-shaped ceiling radiant tube 2 , a floor 3 and a concrete layer 4 .

[0043] The ceiling radiant tube 2 is connected to the steel mesh sheet 1 through the at least one grid of the steel mesh sheet 1 . The connected steel mesh 1 and the ceiling radiant tube 2 are arranged above the bottom surface 301 of the floor, and the connected steel mesh 1 and the ceiling radiant tube 2 are connected to the bottom surface of the floor. 301 spacing is 5mm. The concrete layer 4 is filled in the gaps of the steel mesh sheet 1 , the ceiling radiant tube 2 and the bottom surface 301 of the floor slab.

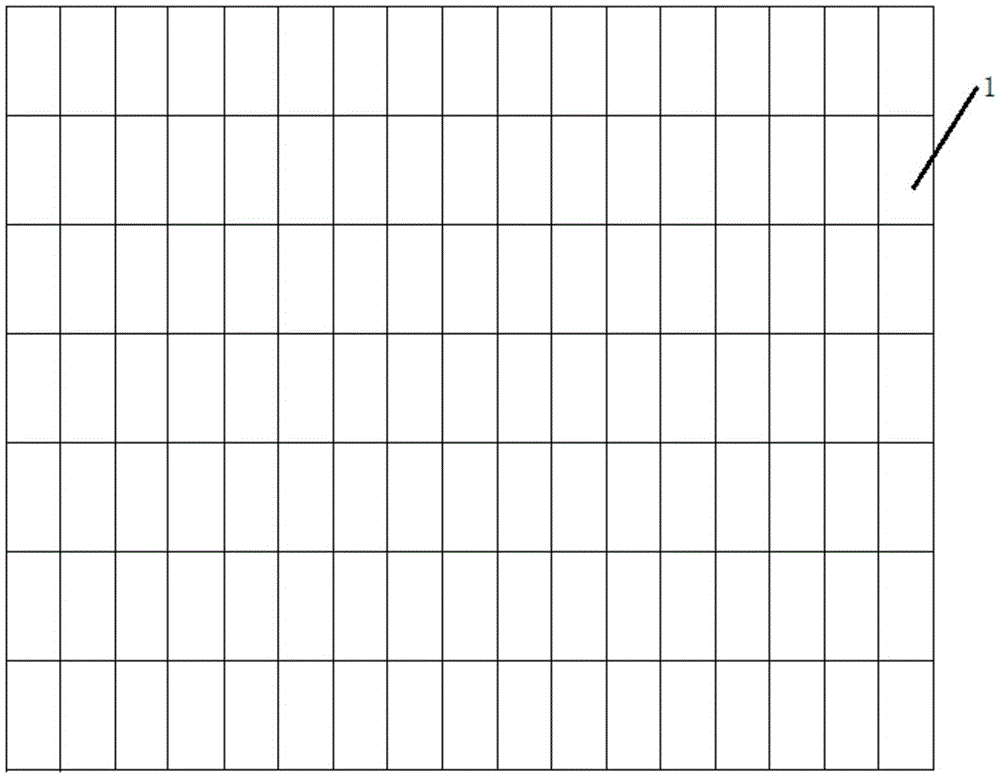

[0044] refer to figure 2 , shows a schematic structural diagram of a steel mesh sheet in Embodim...

Embodiment 2

[0049] On the basis of the first embodiment above, this embodiment also discloses a preferred ceiling radiant tube structure based on buried steel bars. The specific structure of a preferred ceiling radiant tube structure based on buried steel bars disclosed in this embodiment will be described in detail below.

[0050] refer to Figure 4 , shows a schematic structural diagram of a ceiling radiant tube structure based on buried steel bars in Embodiment 2 of the present invention. In this embodiment, the structure of the ceiling radiant tube based on buried steel bars may include: a steel mesh sheet 1 , an "S" shaped ceiling radiant tube 2 , a floor 3 and a concrete layer 4 .

[0051] The ceiling radiant tube 2 is connected to the steel mesh sheet 1 through the at least one grid of the steel mesh sheet 1 . The connected steel mesh 1 and the ceiling radiant tube 2 are arranged above the bottom surface 301 of the floor, and the connected steel mesh 1 and the ceiling radiant tub...

Embodiment 3

[0066] In combination with the above-mentioned device embodiments, this embodiment discloses the steps and procedures of a construction method based on a ceiling radiant tube structure buried under steel bars. refer to Figure 5 , shows a flow chart of steps of a construction method based on a ceiling radiant tube structure buried under steel bars in Embodiment 3 of the present invention. combined with the above Figure 1-Figure 4 , in this embodiment, the construction method of the ceiling radiant tube structure based on buried steel bars may specifically include:

[0067] Step 502, setting the reinforcement mesh sheet 1 including at least one grid.

[0068] Step 504 , connecting the "S"-shaped ceiling radiant tube 2 to the steel mesh sheet 1 through the at least one grid of the steel mesh sheet 1 .

[0069] Step 506, placing the steel mesh 1 connected with the ceiling radiant tube 2 above the bottom surface 301 of the floor, and the steel mesh 1 connected with the ceiling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com