Wall brick with glaze layer

A glazed layer and wall tile technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of lack of integrity, increase operation time, and lack of firmness, save manpower and material resources, reduce operation time, and have strong integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

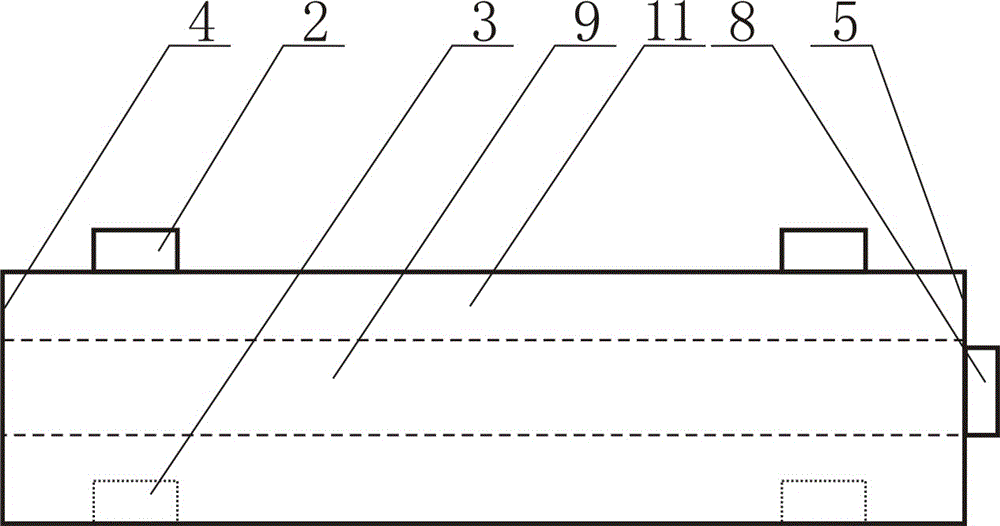

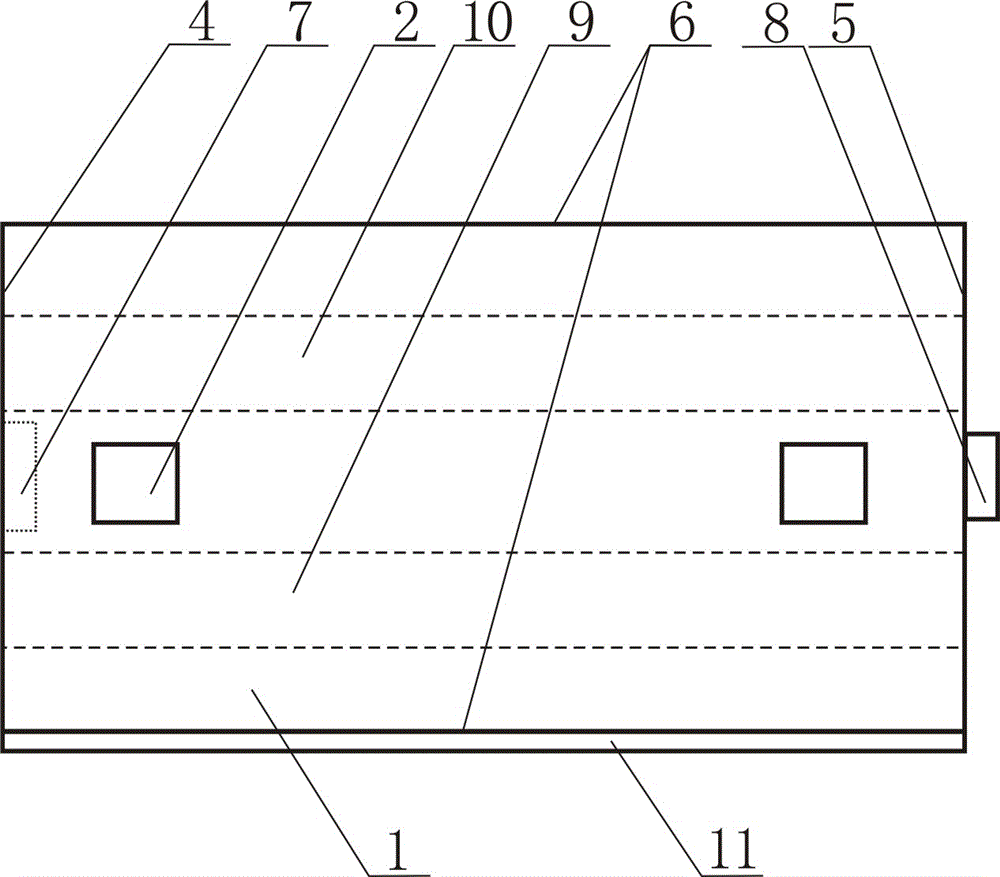

[0015] Such as figure 1 , 2 As shown, the wall tile with the glaze layer includes a brick body 1, the upper surface of the brick body 1 is provided with a positioning protrusion 2, and the lower surface of the brick body 1 is provided with a positioning protrusion corresponding to the positioning protrusion. Adaptive positioning groove 3. There are two positioning protrusions 2, and the two positioning protrusions are respectively close to the left end 4 of the brick body and the right end 5 of the brick body, and the straight line where the two positioning protrusions are located is parallel to the side 6 of the brick body , the positioning groove 3 is also provided with two, and corresponding to the positioning protrusion 2. The cross-section of the positioning protrusion 2 is square, and the positioning groove is a square groove, of course, it can also be designed as a circular groove.

[0016] With the above structure, the positioning protrusions can also be provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com