A special maintenance ladder for power supply

A ladder frame and vertical rod technology, which is applied in the direction of ladders, overhead lines/cable equipment, buildings, etc., can solve the problems of uncontrollable lifting height, single function of maintenance ladder, and unstable high-voltage lines, etc., to improve operation safety and reduce handling The effect of labor intensity and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

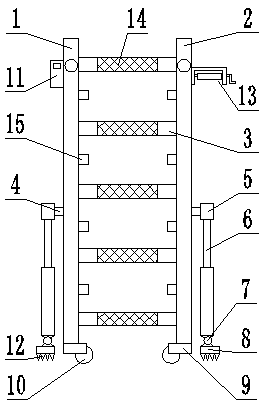

[0024] see figure 1 , Figure 4 , a schematic structural diagram of a maintenance ladder dedicated to power supply provided by an embodiment of the present invention. A maintenance ladder dedicated to power supply according to the present invention includes a ladder frame and a cross bar 3 connected to the ladder frame. The ladder frame includes a first longitudinal bar 1 And the second longitudinal bar 2, also includes two telescopic support mechanisms 6, the two telescopic support mechanisms 6 are located on the left side of the first longitudinal bar 1 and the right side of the second longitudinal bar 2, which is an adjustable support height mechanism; a fixed connection structure 4 and a right-angle sleeve 5 are provided between the upper end of the telescopic support mechanism 6 and the middle or lower side of the first longitudinal rod 1 and the second longitudinal rod 2, and the fixed connection The structure 4 is a connection structure for fixing the telescopic suppor...

Embodiment 2

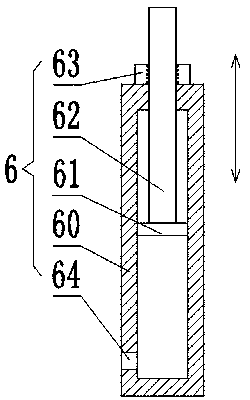

[0030]Except that telescopic support mechanism 6 cooperates with fixed connection structure 4, other structures are the same as Embodiment 1. In this embodiment, please refer to Figure 5 , provided by the embodiment of the present invention figure 1 The structural diagram of the telescopic support mechanism in , the telescopic support mechanism 6 includes a sleeve 60, and the top and bottom of the sleeve 60 are inserted with a positive threaded rod 62 and a reverse threaded rod 65 through the installation through hole, and the positive threaded rod The top of 62 is fixedly connected with the right-angle sleeve 5, the top of the reverse threaded rod 65 is hinged with the hinge 7, and the bottoms of the positive threaded rod 62 and the reversed threaded rod 65 are respectively provided with stoppers 61, the sleeve 60 A pressure relief through hole 64 is provided on the side wall of one end for discharging the gas in the sleeve 60 . The outer wall of the positively threaded rod...

Embodiment 3

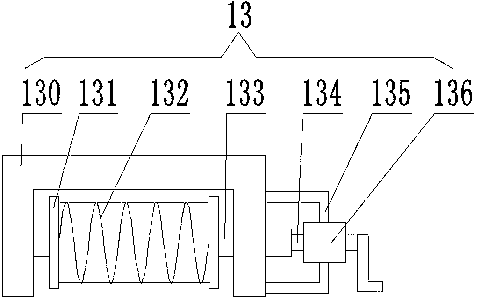

[0033] Except that telescopic support mechanism 6 cooperates with fixed connection structure 4, other structures are the same as Embodiment 1. In this embodiment, please refer to Figure 6 , provided by the embodiment of the present invention figure 1 The schematic diagram of the fixed connection structure in , the surface of the connection side of the right-angle sleeve 5 and the fixed connection structure 4 is provided with a key through hole 51, the lower end of the right-angle sleeve 5 is fixedly connected with the upper end of the telescopic support mechanism 6, and the fixed connection The structure 4 includes a key shaft 41 and a key 42 provided with key slots, and the key slots include but not limited to nine.

[0034] During use, the right-angle sleeve 5 is sleeved on the key shaft 41 provided with a keyway, and the right-angle sleeve 5 is rotated to a reasonable angle according to actual needs, and the key 42 passes through the through hole 51 of the right-angle slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com