Longitudinal temperature measurement freezing apparatus and method

A freezer, vertical technology, used in earth-moving drilling, shaft equipment, mining equipment, etc., can solve the problems of material, labor and man-hour waste, high-pressure hose is not easy to disassemble, etc., to speed up the monitoring process, high test efficiency, guarantee freezing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

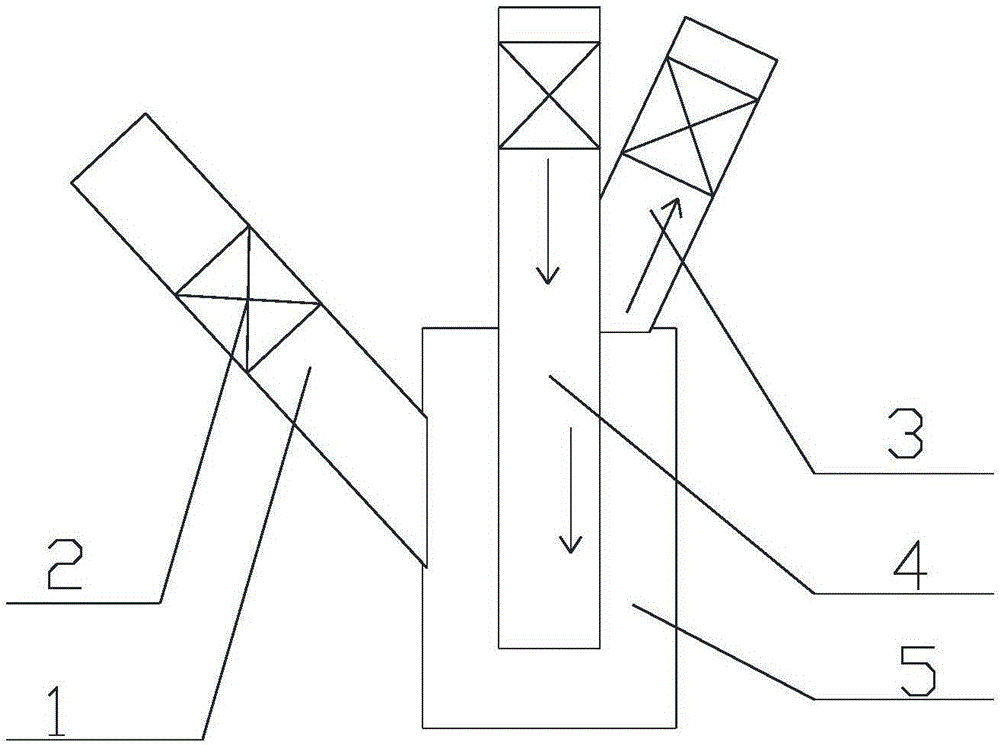

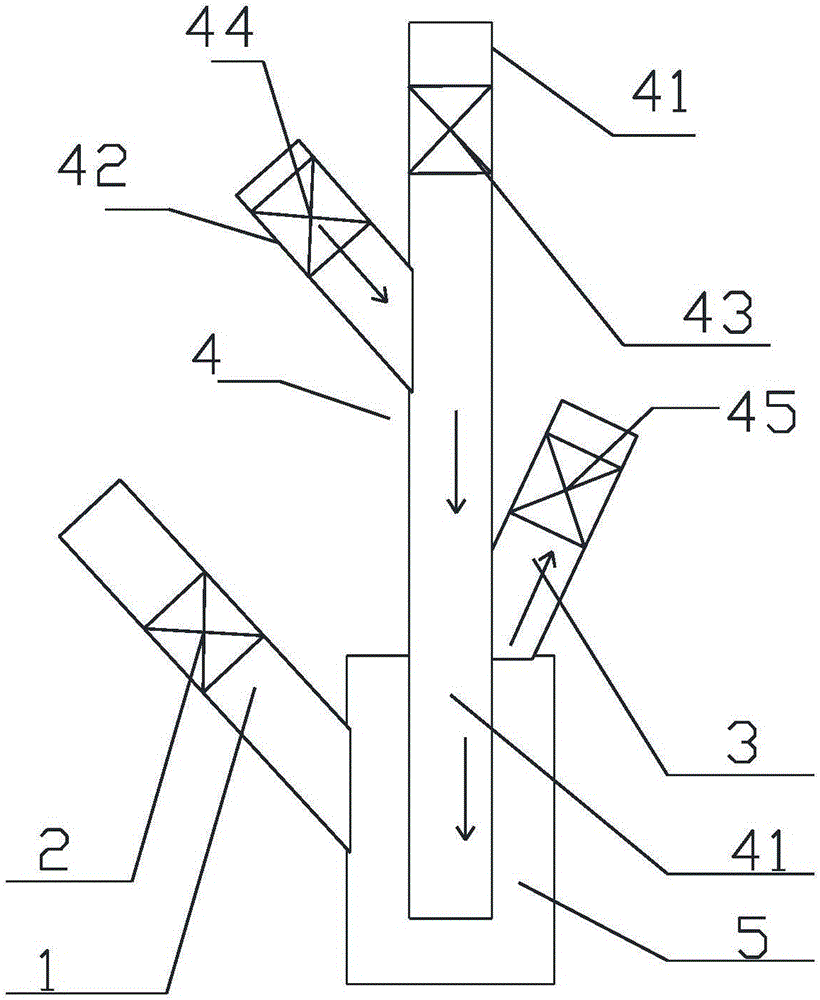

[0023] Such as figure 2 As shown, the freezer used for longitudinal temperature measurement includes a bypass pipe 1, a first gate valve 2, a return pipe 3, a water inlet pipe 4 and a freezer head 5, and the first gate valve 2 is installed in the bypass pipe 1, the bypass pipe 1, the return pipe 3 and the water inlet pipe 4 are respectively connected to the head of the freezer 5 and are in fluid communication; the water inlet pipe 4 is composed of a straight pipe 41 and a side pipe A tee pipe composed of pipes 42; a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com