Self-adjustment jet type comb tooth vapor sealing structure for turbomachine

A turbomachinery, jet technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of reduced reliability and complex structure of the unit, optimize the angle of attack, improve the efficiency of the stage, reduce the mixed flow and The effect of angle of attack loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

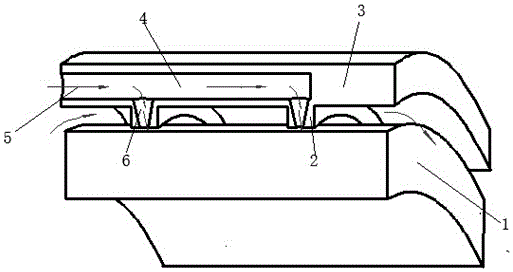

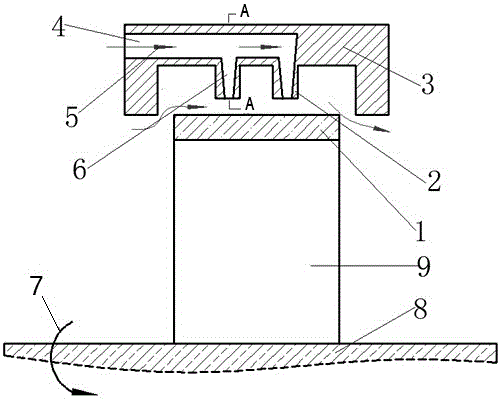

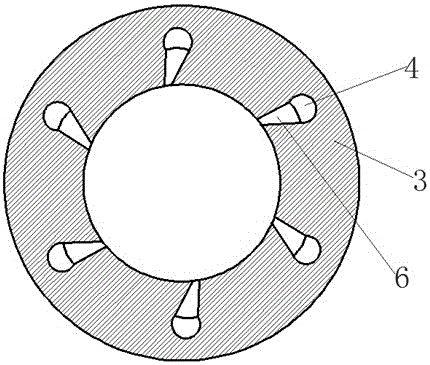

[0015] Such as Figure 1 to Figure 3 As shown, a self-adjusting air-jet comb-tooth seal structure that reduces the excitation force and mixed flow loss of the turbine blade tip includes: shroud 1, comb-type seal teeth 2, support shell 3, drainage holes 4, gradual Shrink nozzle 6, rotor 8, impeller 9.

[0016] The support shell 3 is fixed on the inner surface of the cylinder, the support shell 3 is provided with a drainage hole 4, and the comb seal 2 is provided with a tapered nozzle 6, and the drainage hole 4 communicates with the tapered nozzle 6 to form the flow of leakage fluid channel, the fluid can expand and accelerate in the converging nozzle 6.

[0017] Such as figure 1 , As shown in 2, a comb seal tooth 2 is provided between the support shell 3 and the shroud 1, and there is a gap between the comb seal tooth 2 and the shroud 1. The shroud 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com