Small modularization heat dissipation device

A technology of impeller and flashlight, which is applied to pump devices, components of pumping devices for elastic fluids, and non-variable pumps, etc. It can solve problems such as single application scenarios, expensive fans, and limited air output, and achieve volumetric Small size, easy assembly, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

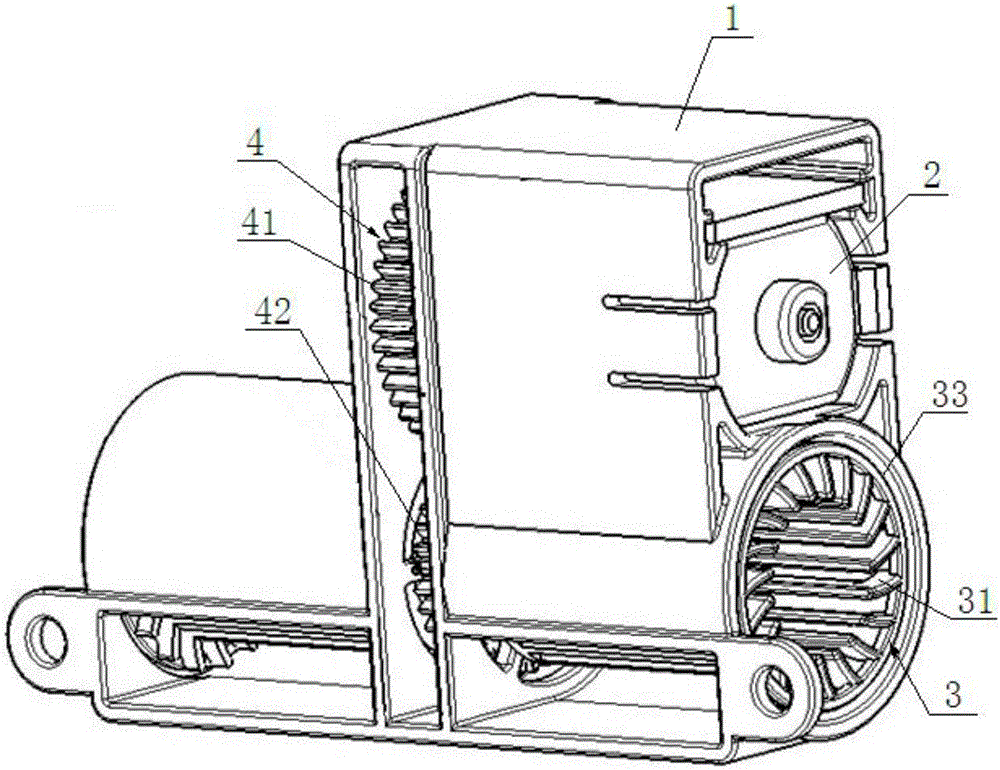

[0016] Below according to the attached Figure 1 ~ Figure 3 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

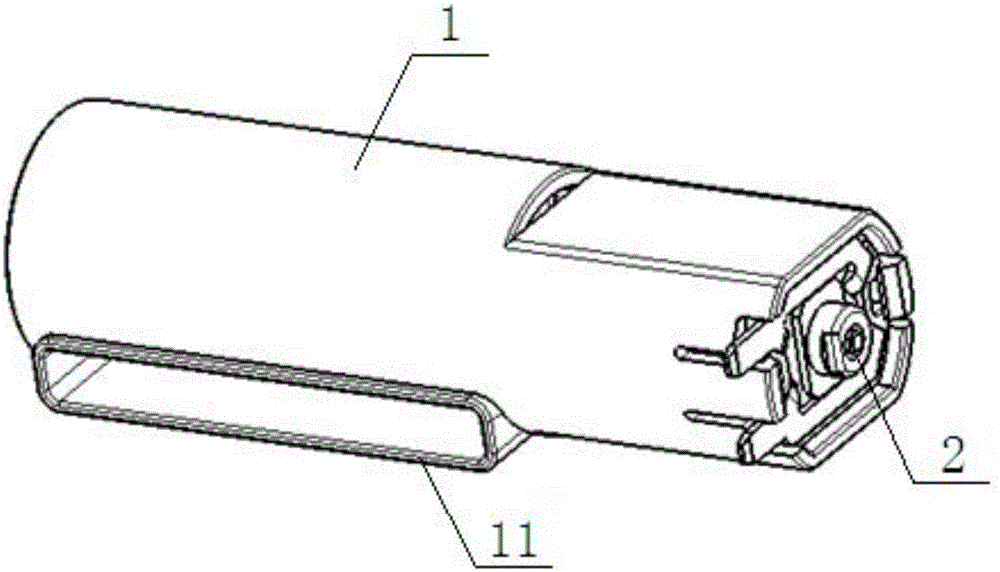

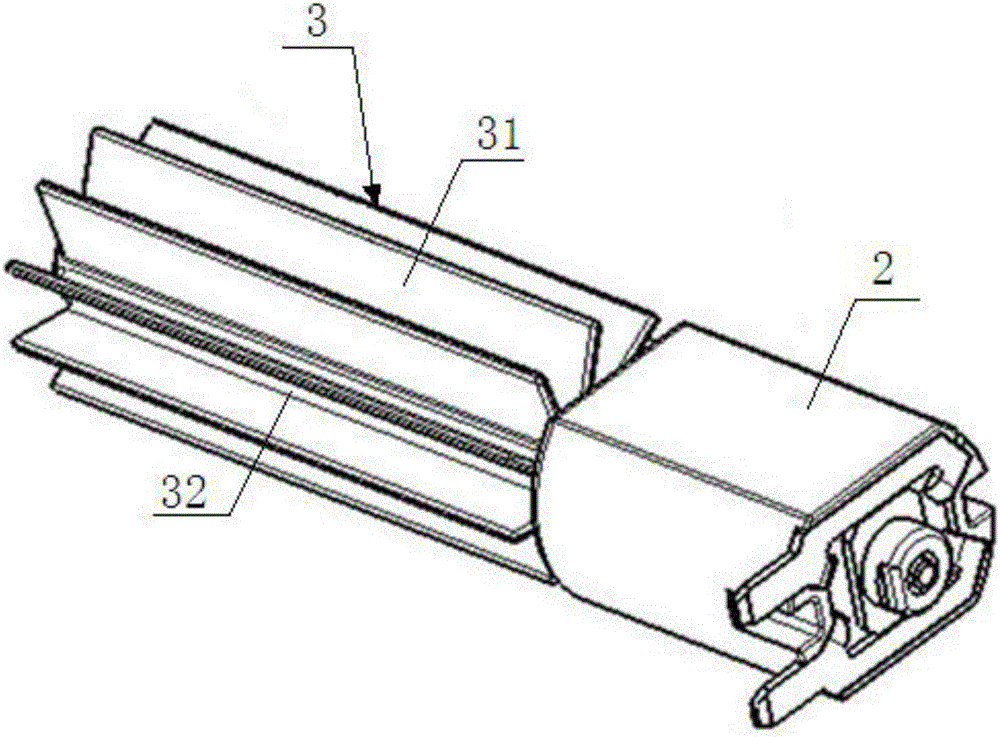

[0017] see figure 1 with figure 2 , a small modular heat dissipation device implemented in the present invention includes a housing 1, a DC brushed motor 2 and an impeller 3, and the DC brushed motor 2 is connected to the impeller 3 by transmission. The housing 1 forms a chamber (not shown), the impeller 3 is arranged in the chamber, the housing 1 forms an air outlet 11 at a position corresponding to the chamber, and the air outlet 11 communicates with the chamber and along the The axial direction of the impeller 3 is provided. In this embodiment, the chamber is cylindrical, the axial direction of the chamber is the same as the axial direction of the impeller 3 in the chamber, and the casing 1 extends along the tangential direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com