Embedment type nut used for drilling jumbo propeller

A technology for rock drilling rigs and thrusters, which is applied in the directions of nuts, threaded fasteners, drilling equipment, etc., can solve the problems of heavy workload and can only be installed on the outside of the aluminum alloy frame, and achieves convenient installation and maintenance. The effect of reducing the risk of interference and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

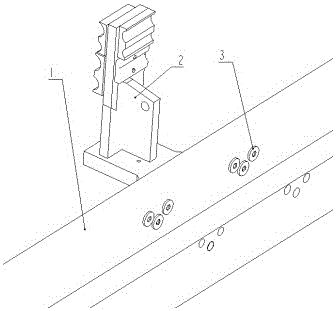

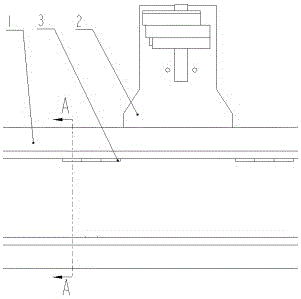

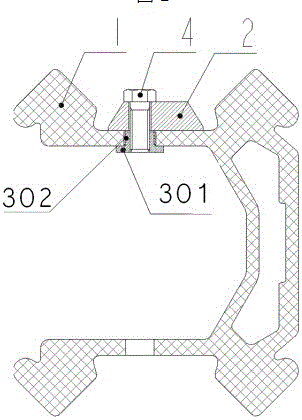

[0016] Such as Figures 1 to 3 As shown, a mosaic nut for a propeller of a rock drilling rig includes a U-shaped aluminum alloy beam 1 and an oil pipe support 2; it also includes an inlay nut 3 and a bolt 4, wherein the oil pipe support 2 passes and bolts 4 are fixed on the U-shaped aluminum alloy beam 1; the inlaid nut 3 is installed inside the U-shaped aluminum alloy frame 1, and the inlaid nut 3 includes a flat part 301 and a protruding part 302.

[0017] As a further improvement of the present invention, the axial through hole of the embedded nut 3 is processed with a right-handed internal thread.

[0018] As a further improvement of the present invention, in the embedded nut 3, the protruding portion 302 is processed with a left-handed external thread.

[0019] As a further improvement of the present invention, the U-shaped aluminum alloy beam 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com