Electromagnetically ventilating spring pressure brake in the form of a multi-circle triangular brake

A technology of spring pressure and brakes, applied in the direction of brake types, brake components, automatic brakes, etc., can solve the problems of local manufacturing of complex parts, operation and installation of brakes, etc., to achieve low manufacturing costs, simple and compact structure, and resource protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

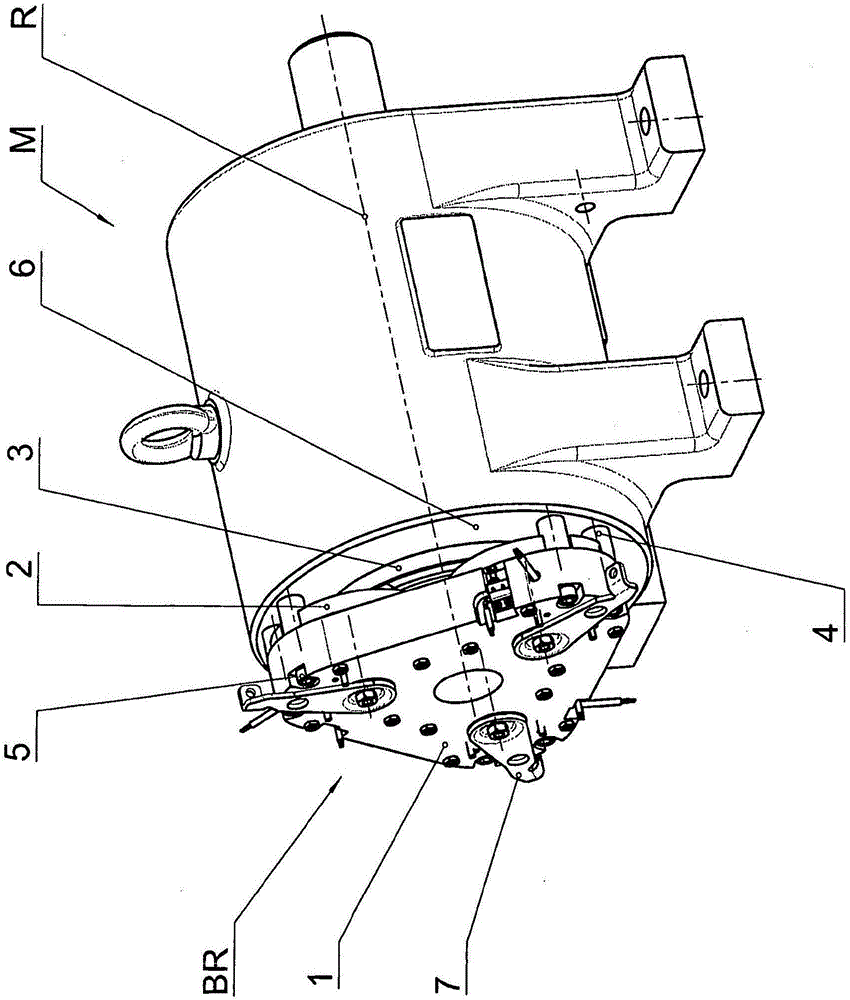

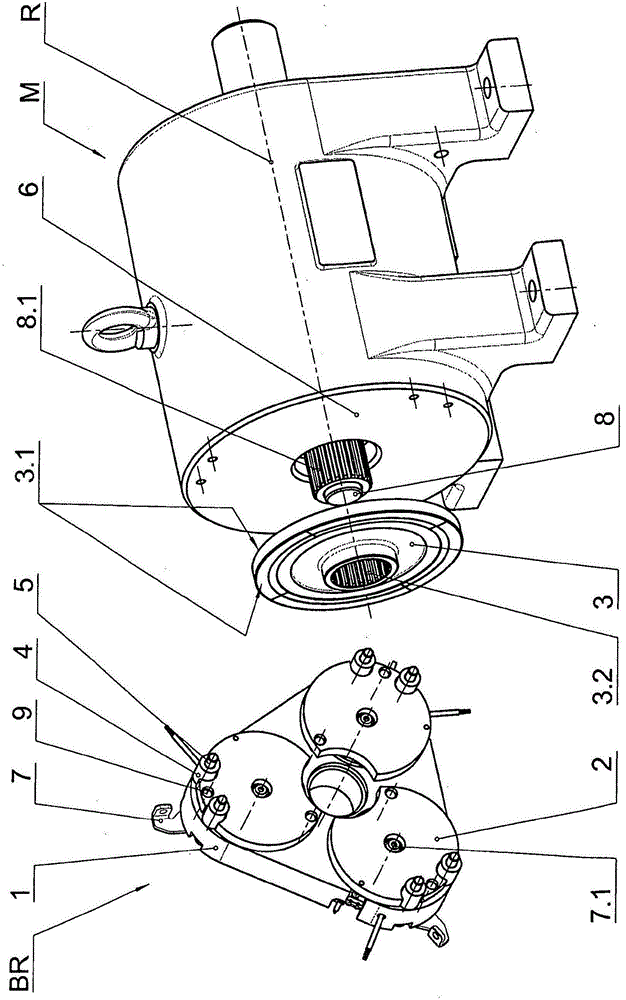

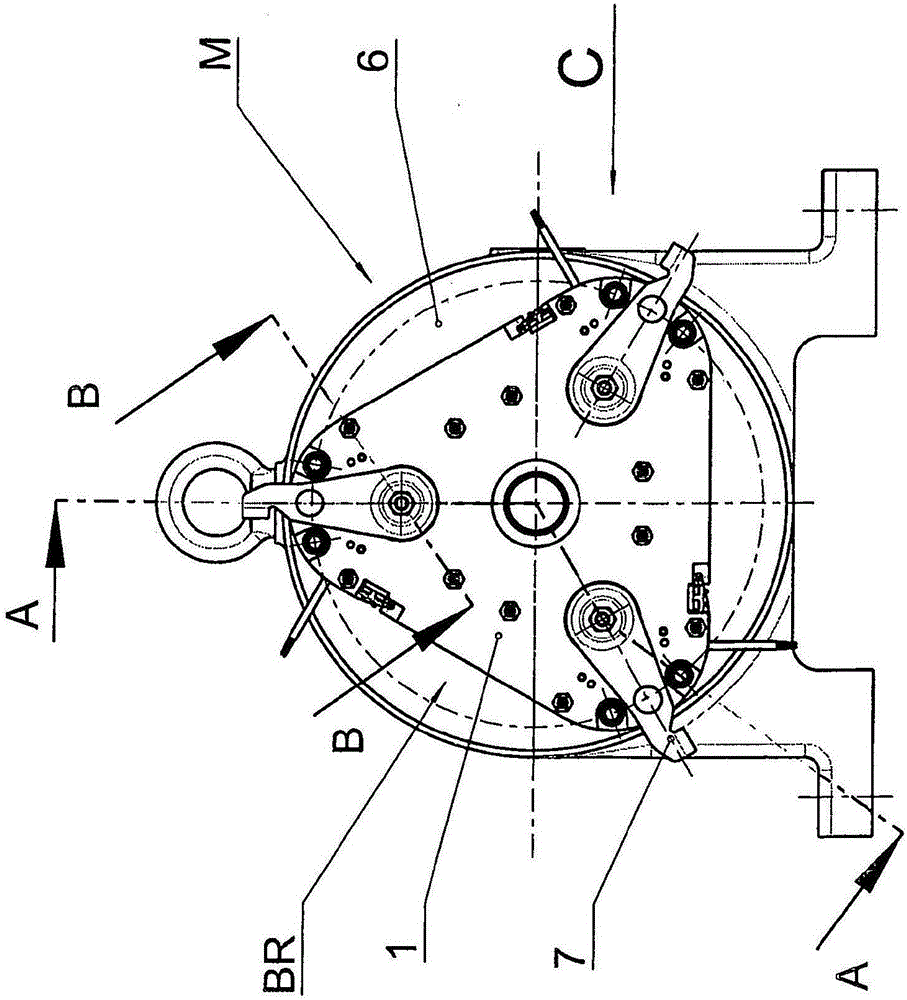

[0041] From figure 1 The basic structure of the spring pressure brake BR according to the invention and its mounting on the end wall 6 of the motor M can be seen in . Accordingly, the spring pressure brake BR is mounted concentrically to the axis of rotation R of the motor M on the machine wall 6 , wherein the coil carrier 1 of the brake BR is fixedly connected to the motor M via spacer bushes 4 and bolts 5 .

[0042] The coil former 1 is equipped with three armature disks 2 which are axially movable relative to the coil former 1 but mounted in a rotationally fixed manner. Between the armature disk 2 and the mating friction surface 6 there is a brake rotor 3 which is equipped with an annular friction lining 3 . On the side of the coil carrier facing away from the motor M there are three manual release levers 7 which are operatively connected to the armature disk 2 of the spring pressure brake BR.

[0043] Further details of the spring pressure brake BR according to the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com