Air-cooling and water-cooling double-acting disc type braking device

A disc brake, double-acting technology, applied in the direction of the brake disc, brake type, brake components, etc., can solve the problems of brake failure, brake shoe friction characteristics change, heat difficult to dissipate quickly, etc., to avoid braking The effect of dynamic failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

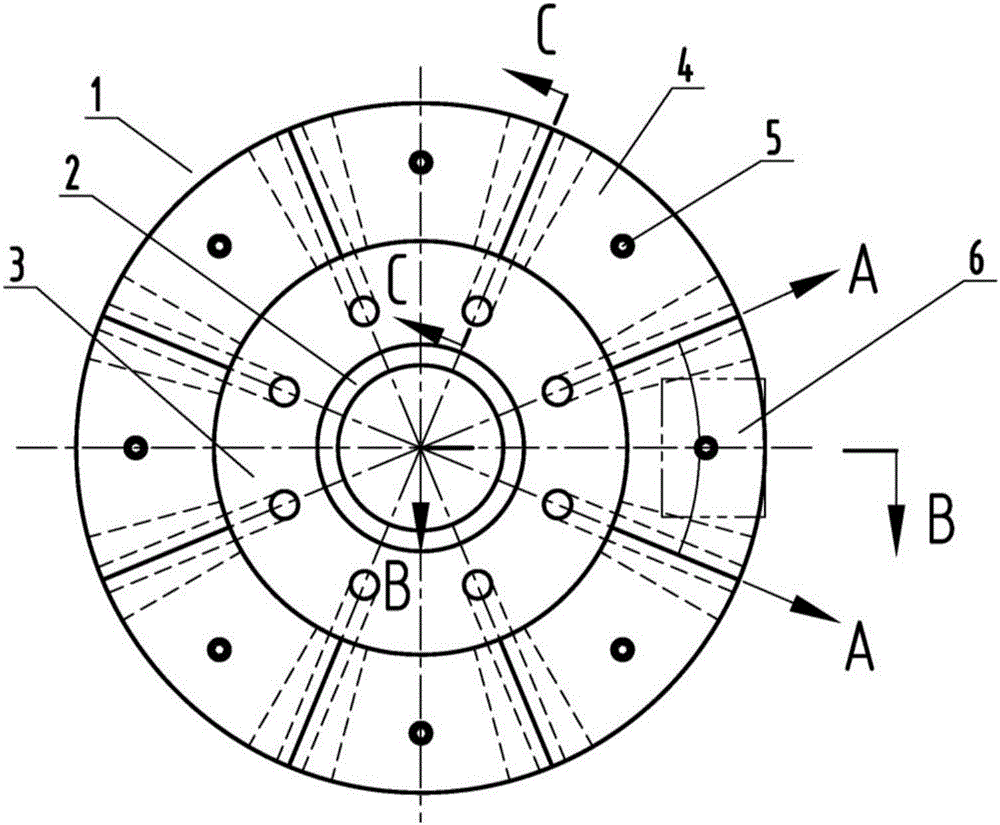

[0022] like figure 1 As shown, a water-cooled plus water-cooled double-acting disc brake device of the present invention includes a brake disc 1 and a brake shoe 6 arranged at the edge of one side of the brake disc 1 .

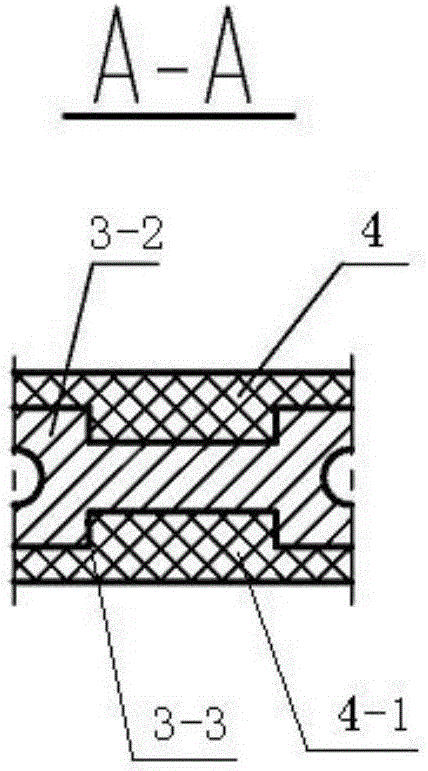

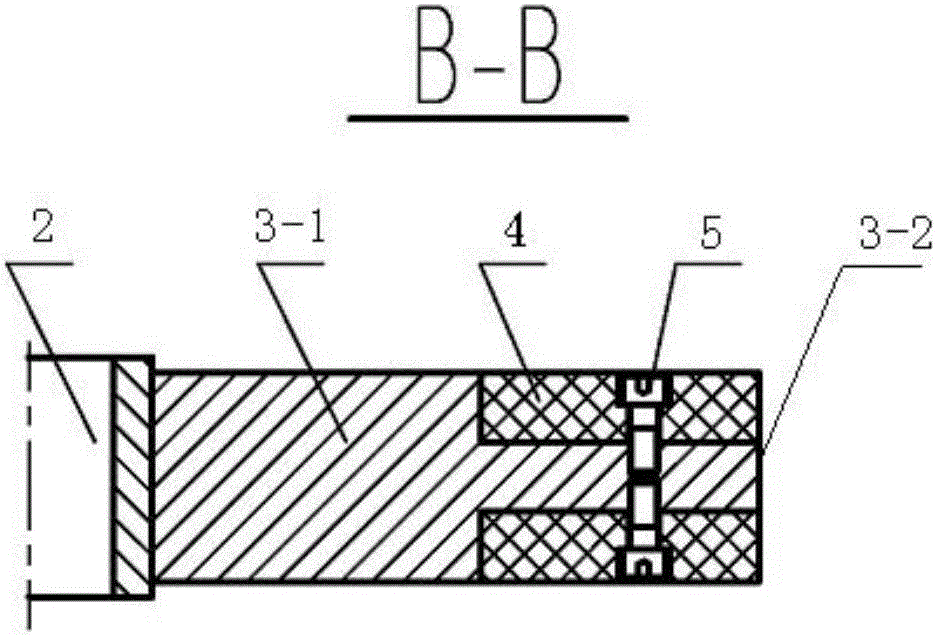

[0023] like figure 1 , 2 , 3 and 4, the brake disc 1 includes a hub 2, a brake disc base 3, an asbestos-free friction plate 4 and screws 5. The brake disc substrate 3 includes an inner annular disc part 3-1 and an outer annular disc part 3-2, the thickness of the inner annular disc part 3-1 is greater than the thickness of the outer annular disc part 3-2, and the hub 2 is connected to the inner annular disc part 3-2. The disk portion 3-1 is fixedly connected. There are several fan-shaped grooves 3-3 evenly distributed along the annular disc surface on both sides of the outer annular disc part 3-2, and the asbestos-free friction plate 4 is fan-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com