Air duct installation method using self-locking air duct hanger

An air duct and hanger technology is applied in the field of air duct installation using self-locking air duct hangers, which can solve problems such as low efficiency, errors in adjustment, and complicated procedures, so as to improve construction efficiency, ensure stability, The effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

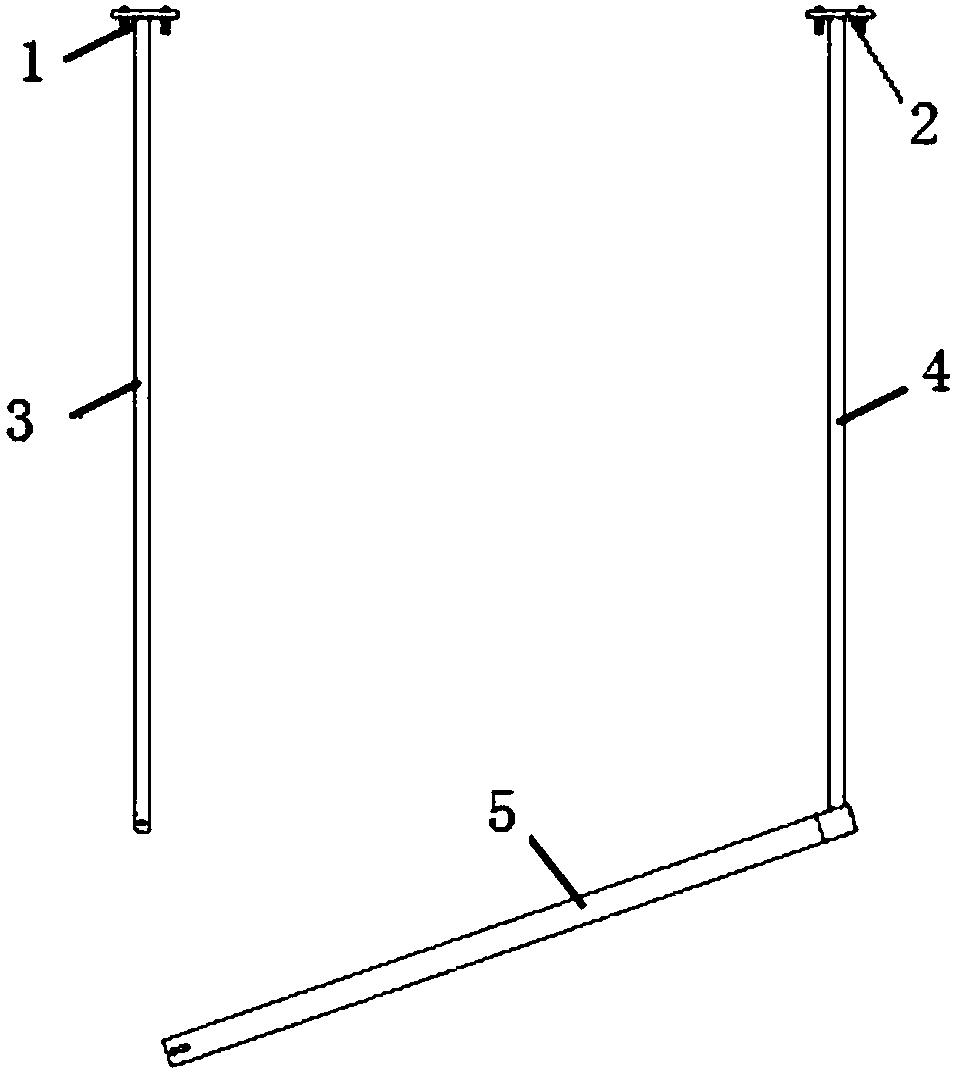

[0032] Example 1, see Figure 1-Figure 7 , a method for installing an air duct using a self-locking air duct hanger, comprising the following steps:

[0033] Step 1: Establish a three-dimensional model of the building according to the building's wind, water, electricity system and floor plan, and set the material, size and other information of the air duct in the three-dimensional model;

[0034] Step 2: Through the in-depth design of the three-dimensional model, the mechanical and electrical professional technicians reasonably arrange the positions of each air duct in the air duct pipeline, and determine the elevation and direction of the air duct pipeline;

[0035] Step 3. According to the deepened air duct model, carry out support and hanger design, and perform force calculation. According to the force calculation results, reasonably arrange the use form and spacing of the air duct hangers, and according to the wind after the layout is completed. Pipe pipe position generat...

Embodiment 2

[0042] Example 2, see Figure 8 , Figure 9 , the difference from Embodiment 1 is that the first boom 3 and the second boom 4 are both telescopic booms; There is an external thread 12, and a waist circle hole 14 is also opened on the telescopic sleeve rod 10; the upper end of the telescopic main rod 11 is provided with a protrusion 15. When the telescopic main rod 11 is inserted into the telescopic sleeve rod 10, the protrusion 15 is placed on the telescopic sleeve rod 10. Inside the waist circular hole 14, the telescopic sleeve rod 10 protrudes; the adjusting nut 13 is arranged on the telescopic sleeve rod 11, and is placed under the protrusion 15. Before installation, adjust the height of the first boom and the second boom, and the T-shaped self-locking member 9 passes through the connection hole and the threaded connection hole, so that the cross arm and the second boom are overlapped, and then the installation is carried out; The jacking device 17 lifts the air duct 18 t...

Embodiment 3

[0043] Embodiment 3 is different from Embodiment 2 in that one of the booms is a height-adjustable telescopic boom, and the other boom is a fixed-height boom.

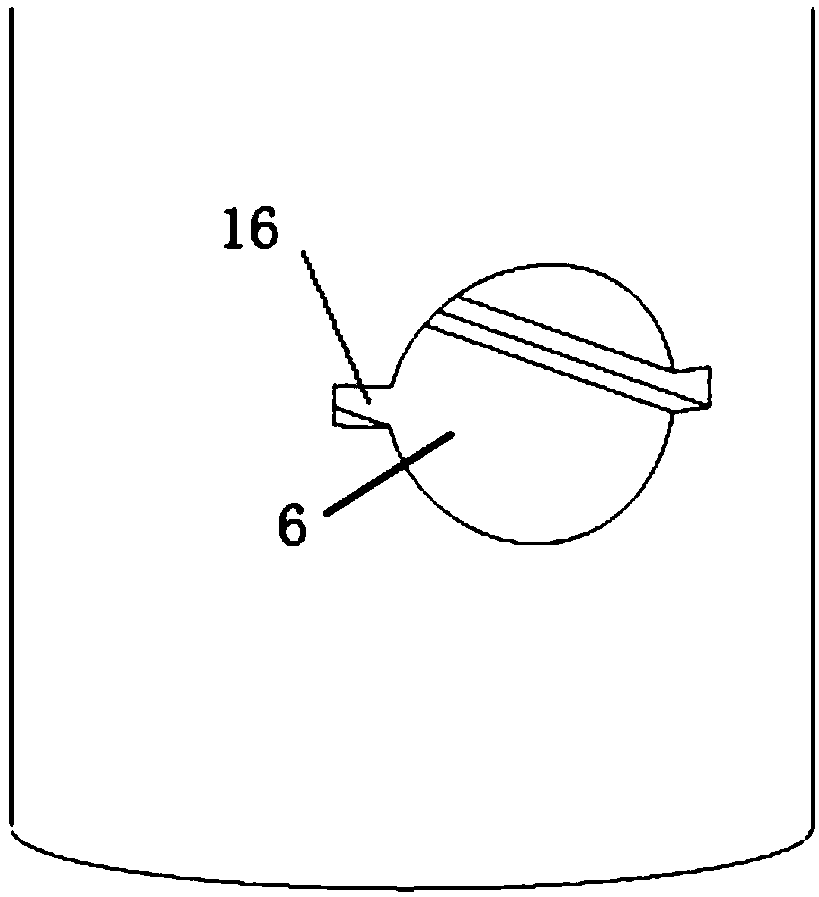

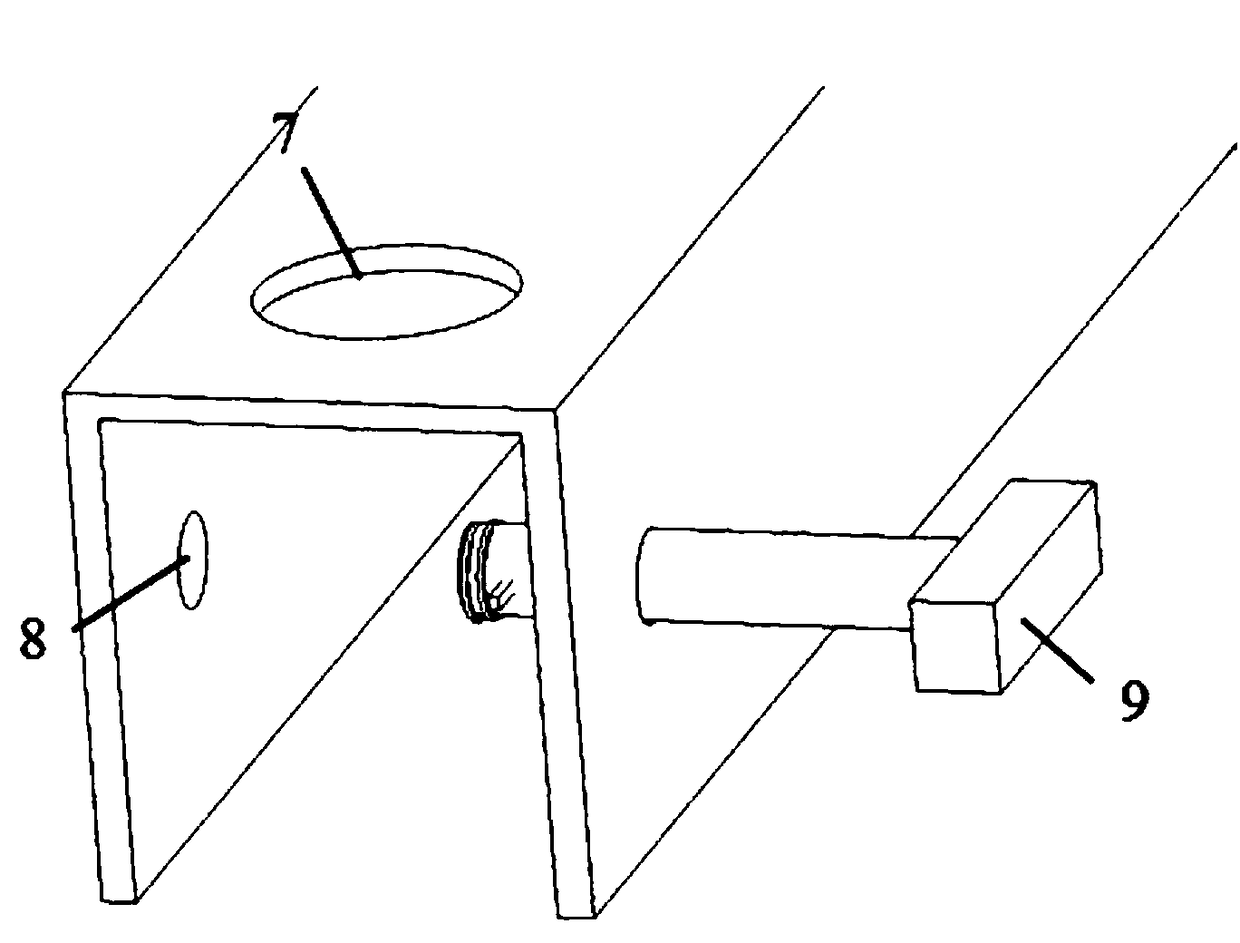

[0044] In the present invention, the height and size of the air duct hanger must be determined before installation, and cannot be changed during installation and use once determined. The self-locking function of the air duct hanger is realized through the T-shaped self-locking member 9 , the first through hole 6 , the insertion hole 7 and the threaded connection hole 8 .

[0045] Example 1 uses a self-locking air duct hanger with a fixed height for air duct installation, Example 2 uses a self-locking air duct hanger with adjustable height for air duct installation, and Example 3 uses one of the hanging rods to be adjustable. The height-adjustable telescopic boom, and the other boom is a self-locking air duct hanger composed of a fixed-height boom for air duct installation. In actual construction, if the floor bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com