LED bulb wick structure made from 360-degree illuminating flexible lamp filament and manufacturing method

A technology of LED light bulbs and filaments, applied in the field of LED lighting, can solve the problems of not meeting the needs of aesthetics and leisure, prone to dark areas, single shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

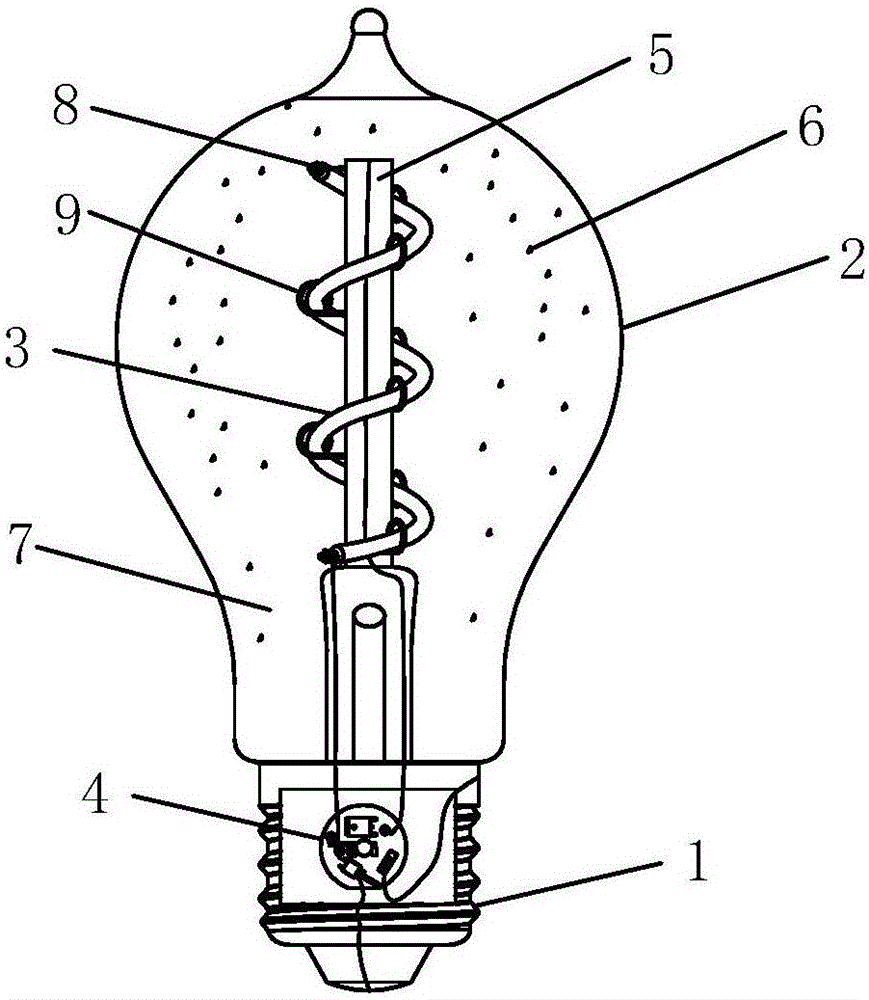

[0044] Such as figure 1 As shown, the wick structure of the LED light bulb made of the 360° luminescent flexible filament described in the embodiment of the present invention is composed of a filament 3, a wick support column 5, and a fixing buckle 9. The support column assembly is connected, and the wick support column 5 is connected with at least one flexible single-color or multi-color semiconductor light-emitting LED filament 3 with a length of 30mm-600mm and any value that can be bent at will. The light-emitting LED filament 3 is distributed in a traditional Inside the lamp housing 2 of bulb shape.

[0045] Further, the filament 3 uses the flexible FPC as the substrate carrier to mount a plurality of semiconductor light-emitting LED chips on the FPC substrate, and coats with high-brightness phosphor powder, so as to realize 360° luminous flexible filament 3, which has high light efficiency and can be bent at will. , folding molding and other characteristics;

[0046] Co...

Embodiment 2

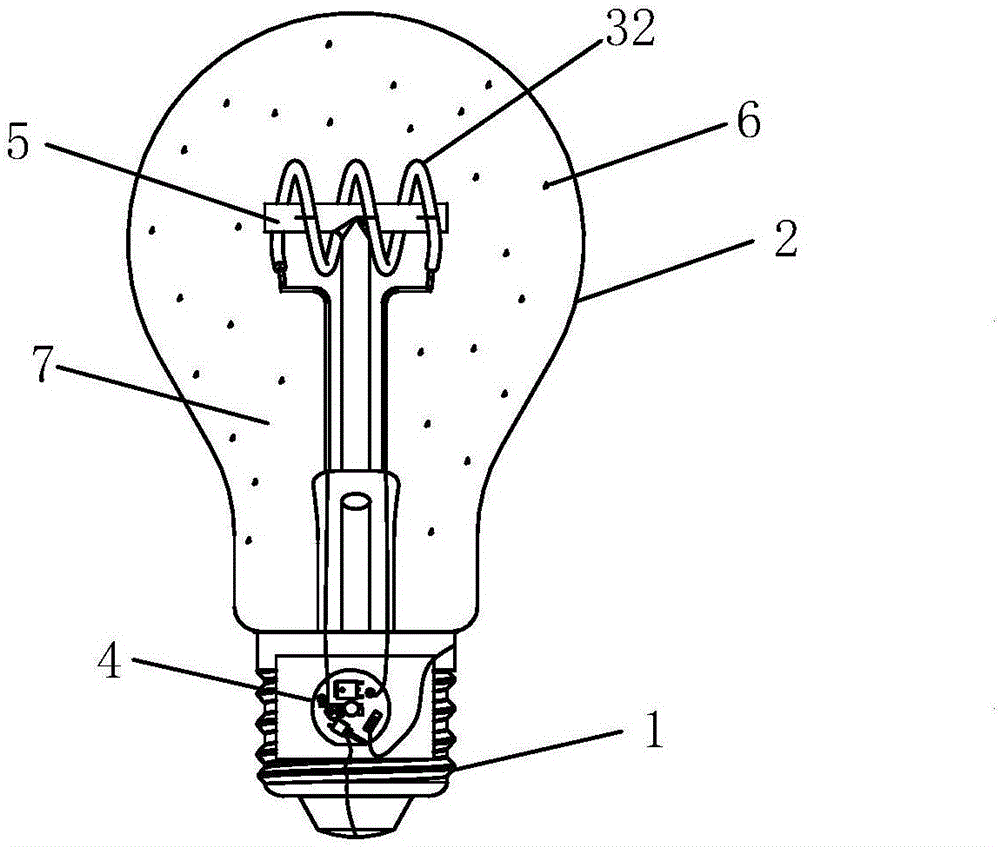

[0050] Such as figure 2As shown, the wick structure of the LED light bulb made of the 360° luminescent flexible filament described in the embodiment of the present invention is composed of a curved filament 32 and a wick support column 5. The wick support column 5 and the support column extending into the lamp housing 2 The components are connected, and the wick support column 5 is connected with at least one curved flexible single-color or multi-color semiconductor light-emitting LED curved filament 32 that can be bent at will. The light-emitting LED curved filament 32 is distributed in a lamp with a traditional light bulb shape. Inside the shell 2; the curved filament 32 is connected to the wick support column 5 through a fixing assembly.

[0051] Further, the two ends of the curved filament 32 are respectively connected to one end of the conductive wire, and then connected to the lamp housing 2 of different shapes through sealing, exhausting, vacuuming and filling with hel...

Embodiment 3

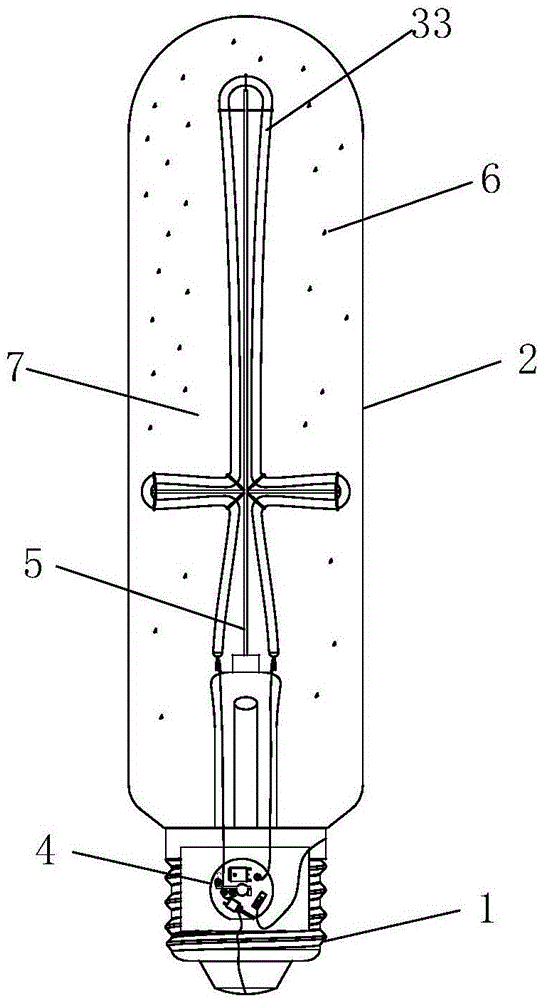

[0054] Such as image 3 As shown, the wick structure of the LED light bulb made of the 360° luminescent flexible filament described in the embodiment of the present invention is composed of a cross-shaped filament 33 and a wick support column 5. The wick support column 5 and the support column extending into the interior of the lamp housing 2 The components are connected, and the wick support column 5 is connected with an LED cross-shaped filament 33, which is distributed in the cylindrical lamp housing 2; the cross-shaped filament 33 and the wick support column 5 are connected by a fixed assembly connect.

[0055] Further, the two ends of the cross-shaped filament 33 are respectively connected to one end of the conductive wire, and then connected to the lamp housing 2 of different shapes through sealing, exhausting, vacuuming and filling with helium to form a unique independent airtight illuminant. The airtight illuminant has a A vacuum chamber 7 and the heat dissipation gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com