Boiler deslagging cooling system and boiler deslagging cooling method

A slag cooling and boiler technology, applied in lighting and heating equipment and other directions, can solve the problems of worsening the operating environment, damage to the drum slag cooler, gas leakage, etc., to achieve the effect of simple process, avoidance of safety accidents, and prevention of gas leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

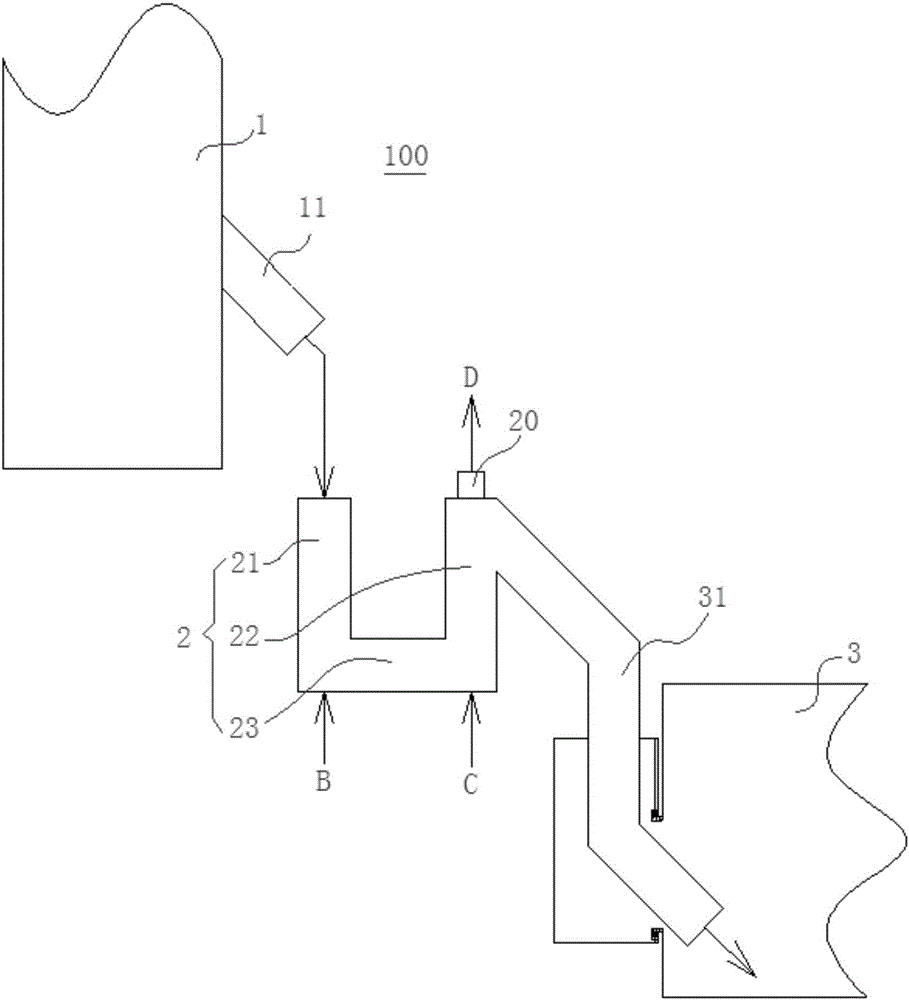

[0063] In the first embodiment, the slagging device 2 is a U-shaped slagging device 2, nitrogen is used as the loosening gas B and fluidizing gas C, and the semi-coke discharged from the boiler 1 as a pyrolysis furnace is cooled as an example to explain in detail.

[0064] refer to figure 1 , the semi-coke (minimum average fluidization velocity Umf=0.2m / s) discharged from the slag discharge pipe 11 of the boiler 1 as a pyrolysis furnace with a particle size of 0-8mm (but not 0mm) enters under the action of gravity The first tube 21 of the U-shaped slagging device 2 forms a material seal. Under the action of the material seal, the pyrolysis gas discharged from the boiler 1 as the pyrolysis furnace cannot enter the second tube under the action of the material seal in the first tube 21. Two pipes 22, at the same time, blast into the U-shaped slagging device 2 an inert gas-nitrogen that does not react with semi-coke and pyrolysis gas as loosening gas B and fluidization gas C, and ...

Embodiment 2

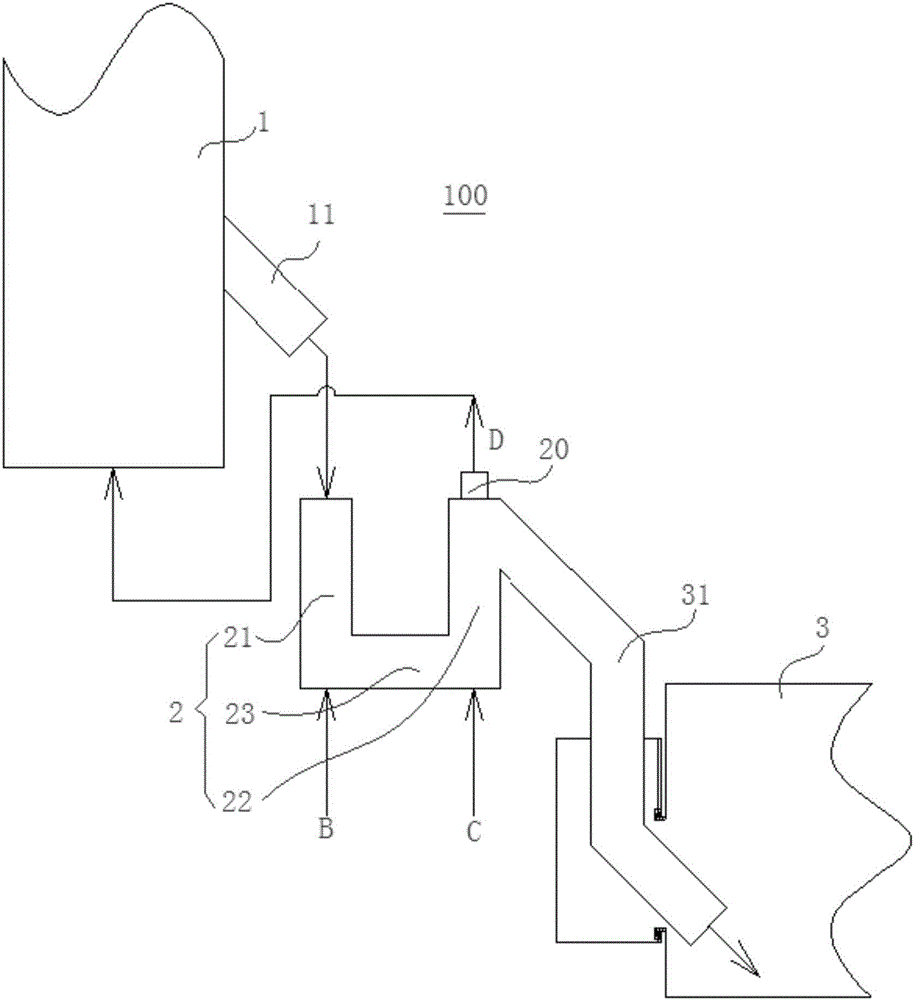

[0066] refer to figure 2 , the structure of the second embodiment is substantially the same as that of the first embodiment, the difference is that in this embodiment, the tail gas port 20 is directly connected to the boiler 1 instead of being connected to the atmosphere. That is to say, the nitrogen gas discharged through the tail gas port 20 can enter the boiler 1 and be used as a pyrolysis protection gas, thereby reducing costs and improving utilization efficiency.

Embodiment 3

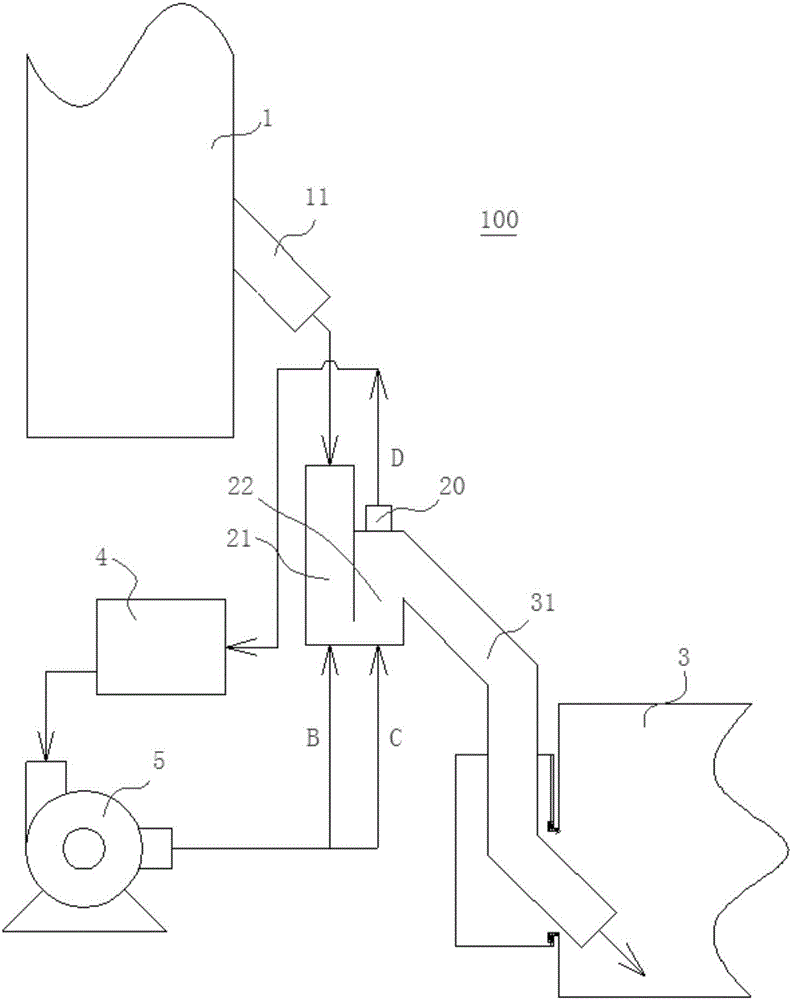

[0068] In the third embodiment, the slagging device 2 is a J-type slagging device 2, nitrogen is used as the loosening gas B and the fluidizing gas C, and the semi-coke discharged from the boiler 1 as a gasifier is cooled as an example to illustrate in detail.

[0069] refer to image 3 , the semi-coke (minimum average fluidization velocity Umf=0.05m / s) discharged from the slagging pipe 11 of the boiler 1 as the gasification furnace with a particle size of 0-1 mm enters the J-shaped slagging device 2 under the action of gravity In the first pipe 21, a material seal is formed. Under the action of the material seal, the synthetic gas discharged from the boiler 1 as a gasification furnace cannot enter the J-shaped second pipe 22 under the effect of the material seal in the first pipe 21. J-type slagging device 2 blows inert gas-nitrogen that does not react with semi-coke and synthetic gas as loosening gas B and fluidization gas C, the flow rate of loosening gas B is 0.025-0.075m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com