Electronic control valve with circulating air guide function

An electronic control and valve technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of easy damage, single function and inconvenience of the air guide valve, and achieve the effect of improving the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

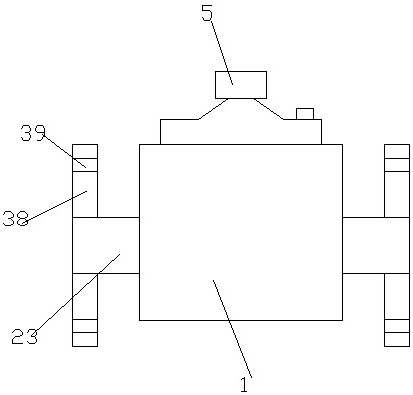

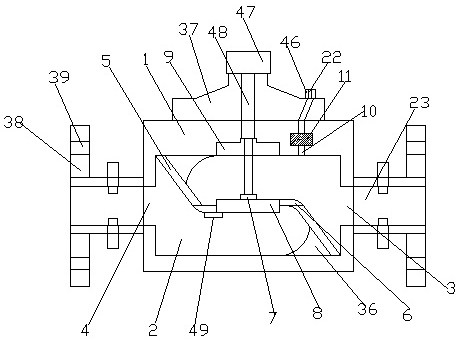

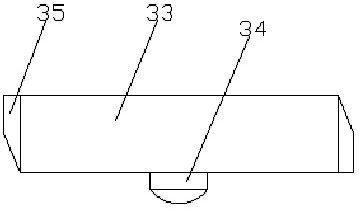

[0042] see Figure 1-8 , according to an embodiment of the present invention, an electronically controlled valve with circulating air guide includes a valve housing 1, a cavity 2 is opened in the valve housing 1, and inlets and outlets are respectively provided at both ends of the cavity 2. Gas port 3 and gas outlet 4, both ends in the cavity 2 are fixed with a sealing swash plate 5, and the end of the sealing swash plate 5 away from the inner wall of the cavity 2 is fixed with a transverse sealing plate 6, so A sealing cover 8 is detachably arranged between the two transverse sealing plates 6, and the sealing cover 8 includes a sealing connecting plate 33, and a displacement sensor 34 is arranged below the sealing connecting plate 33, and the sealing connecting plate 33 Elastic seals 35 are provided on both sides of the cavity, a placement cavity 9 is provided on the top of the cavity 2, a connecting block 7 is provided on the sealing cover 8, and a connecting block 7 is prov...

Embodiment 2

[0045] Such as Figure 6 As shown, the pipe fixing plate 27 includes an arc-shaped splint 31, and an arc-shaped elastic pad 32 is provided on the inner arc of the arc-shaped splint 31 to improve its fixing effect.

Embodiment 3

[0047] Such as figure 2 As shown, arc-shaped deflectors 36 are connected to one side of the sealing sloping plate 5 in the cavity 2 to increase the smoothness of air flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com