External air conditioner wind blocking component

An air conditioner and component technology, applied in the field of external air conditioner windshield components, can solve the problems of air conditioners stopping cooling, lower than the actual room temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

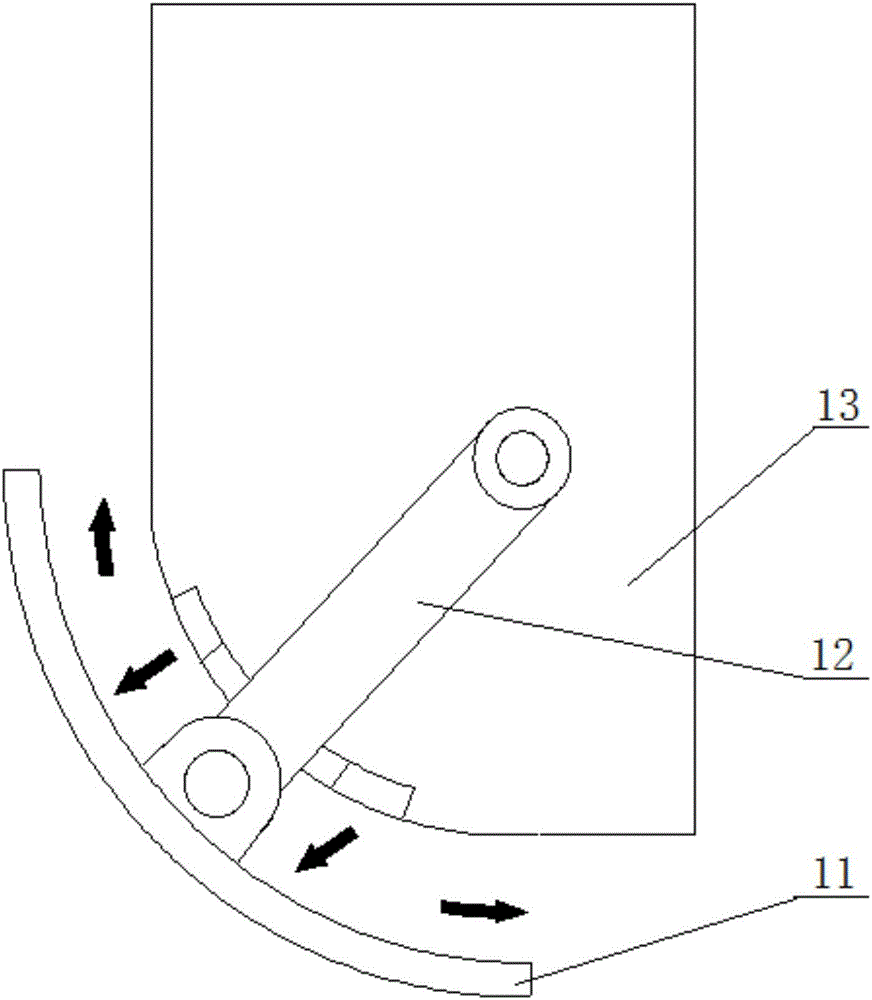

[0036] refer to figure 1 , In the prior art, a windshield 11 is added outside the air conditioner to change the direction of the cold wind blown out of the air outlet, thereby preventing the cold wind from blowing directly to the user. The windshield 11 is connected to the air conditioner casing 13 through two connecting rods 12 respectively arranged on its two sides. The windshield 11 is close to but spaced from the air outlet of the air conditioner. The windshield 11 is a solid structure, and the windshield 11 is arc-shaped. shape and protrudes toward the direction away from the air conditioner housing 13. During air-conditioning refrigeration, the cold wind of the air-conditioning air outlet hits the windshield 11 and is blown upward or backward by the gap between the windshield 11 edge and the air-conditioning casing 13 ( figure 1 The middle black solid arrow shows the travel path of the cold wind). In this way, the cold air blown by the air conditioner will not directly...

Embodiment 2

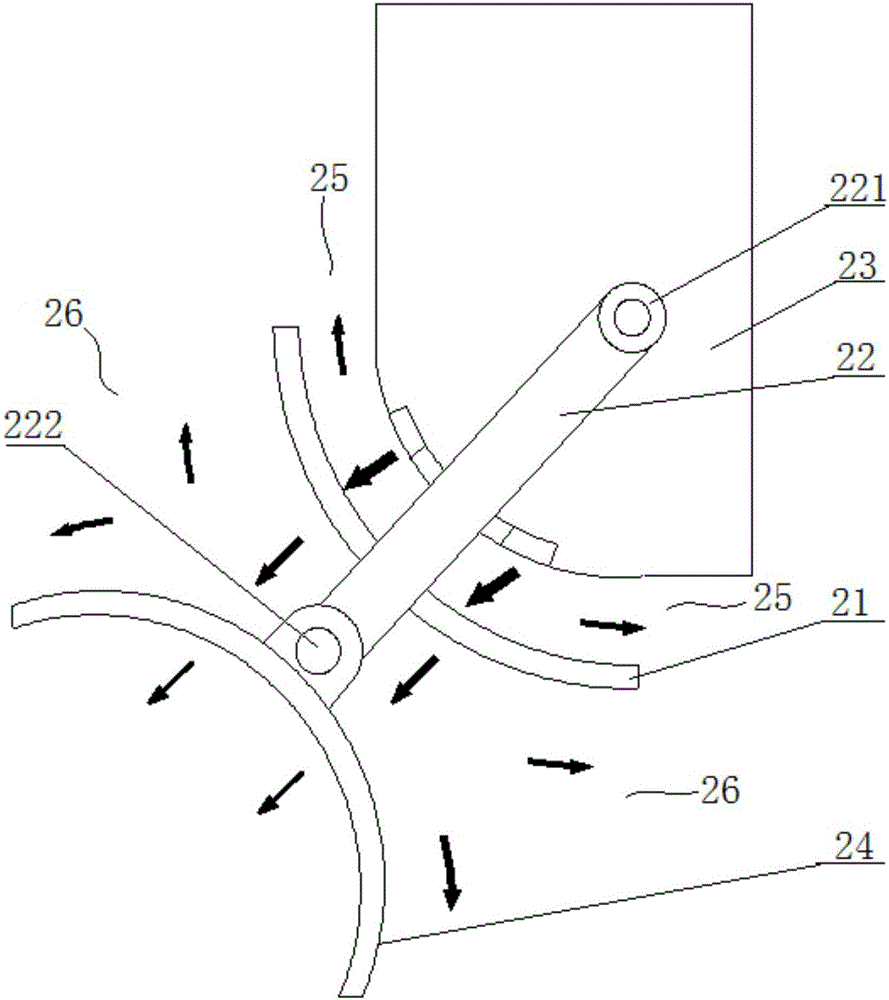

[0062] refer to Figure 6 The difference between the external air conditioner windshield assembly in this embodiment and the first embodiment lies in the structure of the arc-shaped windshield 21 .

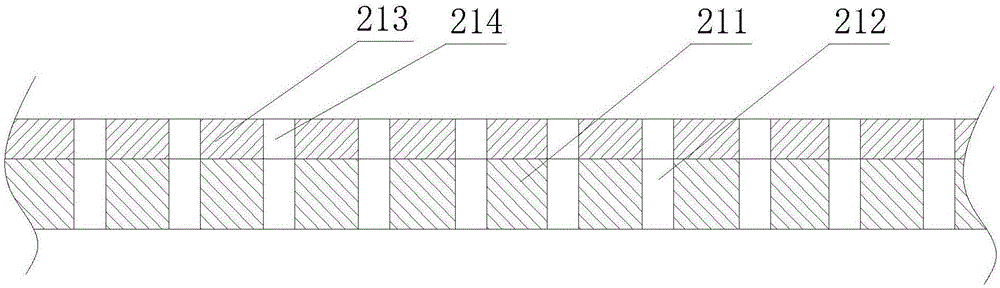

[0063] In this embodiment, the curved windshield 21 is composed of a curved plastic grid 215 and a gauze layer (referred to as the first gauze layer 216 in this embodiment) attached to the curved plastic grid 215, preferably Specifically, the first gauze layer 216 is attached to the inner surface of the arc-shaped plastic grille 215 , wherein the inner surface of the arc-shaped plastic grille 215 refers to the surface facing the air conditioner housing 23 . The arc-shaped plastic grille 215 is composed of an outer frame, a plurality of beams and a plurality of longitudinal beams, the width of the beams and the longitudinal beams is within the range of 1cm-1.5cm, the distance between adjacent beams and the distance between adjacent longitudinal beams The distance is within the ran...

Embodiment 3

[0066] refer to Figure 7 The difference between the external air conditioner windshield assembly in this embodiment and the first embodiment lies in the structure of the secondary windshield 24 .

[0067] The secondary windshield 24 is made up of a plastic grid 245 and a gauze layer (referred to as the second gauze layer 246 in this embodiment) attached to the plastic grid 245. Preferably, the second gauze layer 246 is attached to the The inner surface of the plastic grid 245 , wherein the inner surface of the plastic grid 245 refers to its surface facing the arc-shaped windshield 21 . The plastic grid plate 245 is made of an outer frame, a plurality of crossbeams and a plurality of longitudinal beams, the width of the crossbeams and longitudinal beams is within the range of 1cm-1.5cm, and the distance between adjacent crossbeams and the distance between adjacent longitudinal beams is at Within the range of 2cm-3cm, the total cross-sectional area of the hollowed-out area o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com