Error detection device for hourglass worm

An error detection and toroidal worm technology, which is applied to measuring devices, electromagnetic measuring devices, electrical devices, etc., can solve the problems of inaccurate detection results, high cost, and inability to use the accuracy of worm parts for detection and analysis. The effect of simplicity and convenience, reducing detection cost, wide application value and universality of principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

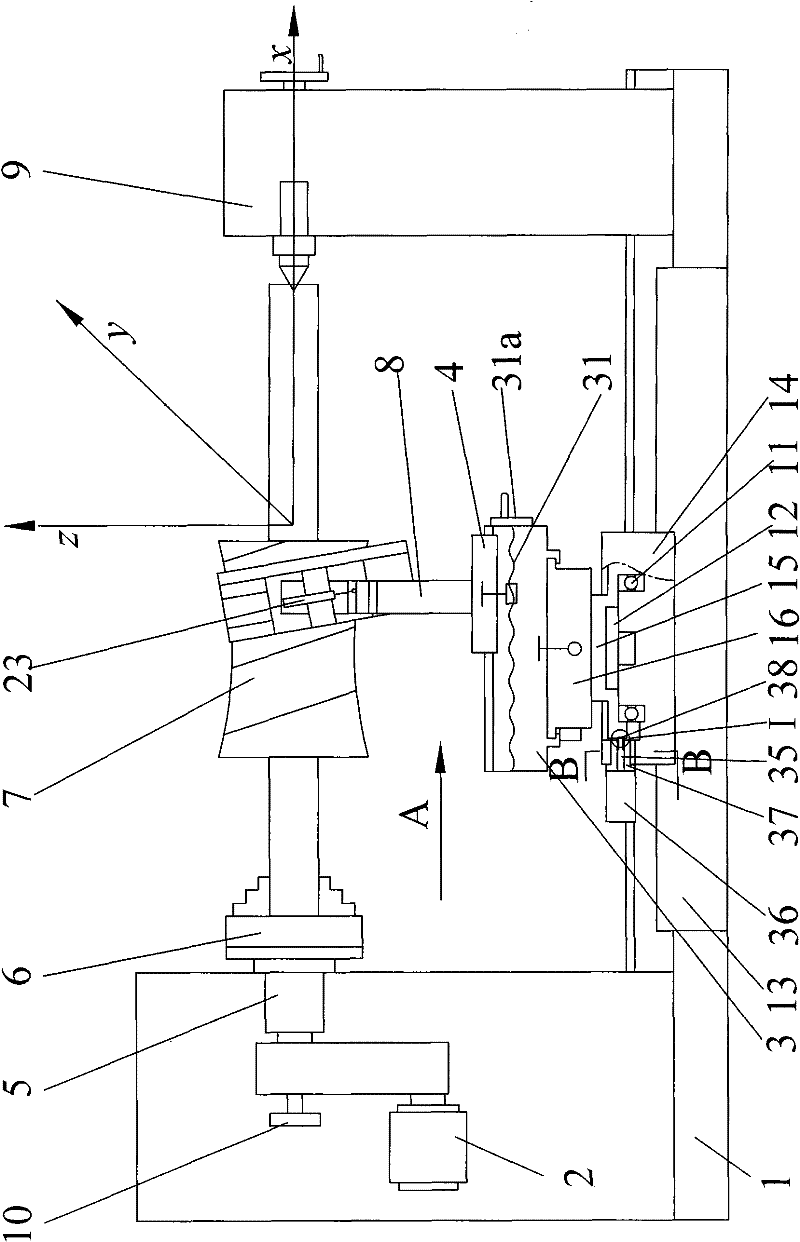

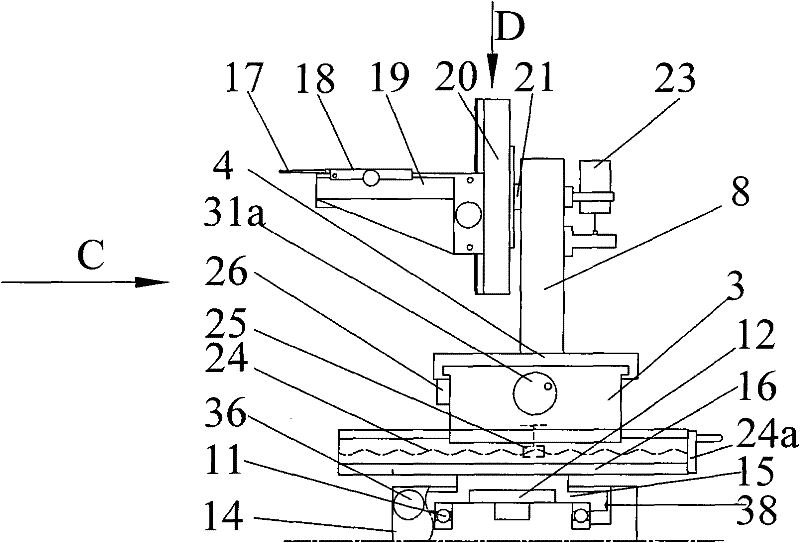

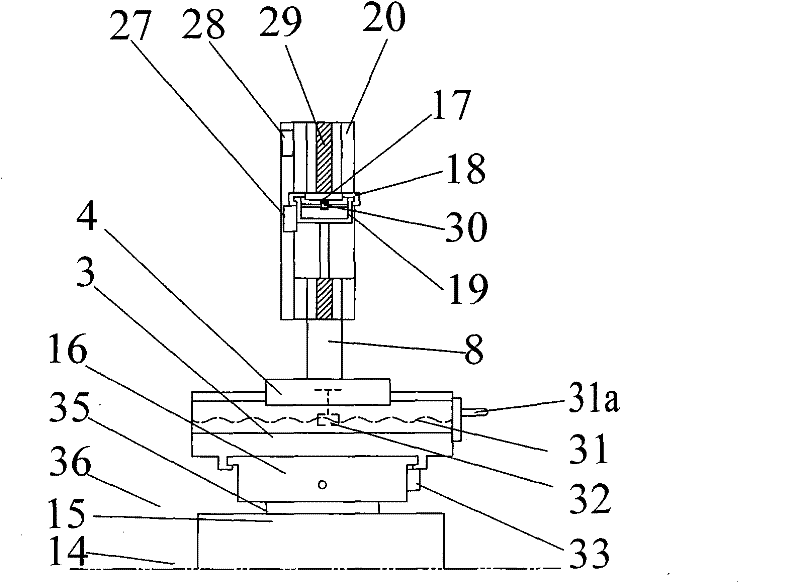

[0028] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along direction A, image 3 for figure 2 View along direction C, Figure 4 for figure 2 View along direction D, Figure 5 for figure 1 Sectional view along B-B direction, Image 6 for figure 1 The enlarged view at I, as shown in the figure: the toroidal worm error detection device of the present embodiment includes a fuselage 1, a main shaft unit and a measuring unit, and the main shaft unit includes a main shaft servo motor 2, a main shaft 5, a workpiece fixture 6 and a tail. Seat 9, the main shaft servo motor 2 drives the main shaft 5 to rotate, and the measured workpiece fixture 6 is fixedly matched with the main shaft 5 in the circumferential direction;

[0029] The measuring unit comprises a base 14, a rotating table 15, a measuring contact 17, a data acquisition system and a computer 34, the base 14 is arranged on the fuselage 1, and the rotating table 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com