Method for measuring tooth surface error of enveloping worm

An error measurement, toroidal worm technology, applied in the direction of mechanical counter/curvature measurement, machine gear/transmission mechanism test, etc., can solve the problems of inaccurate detection results, high cost, and inability to use worm parts for precision detection and analysis, etc., to achieve Extensive universality, lower detection cost, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

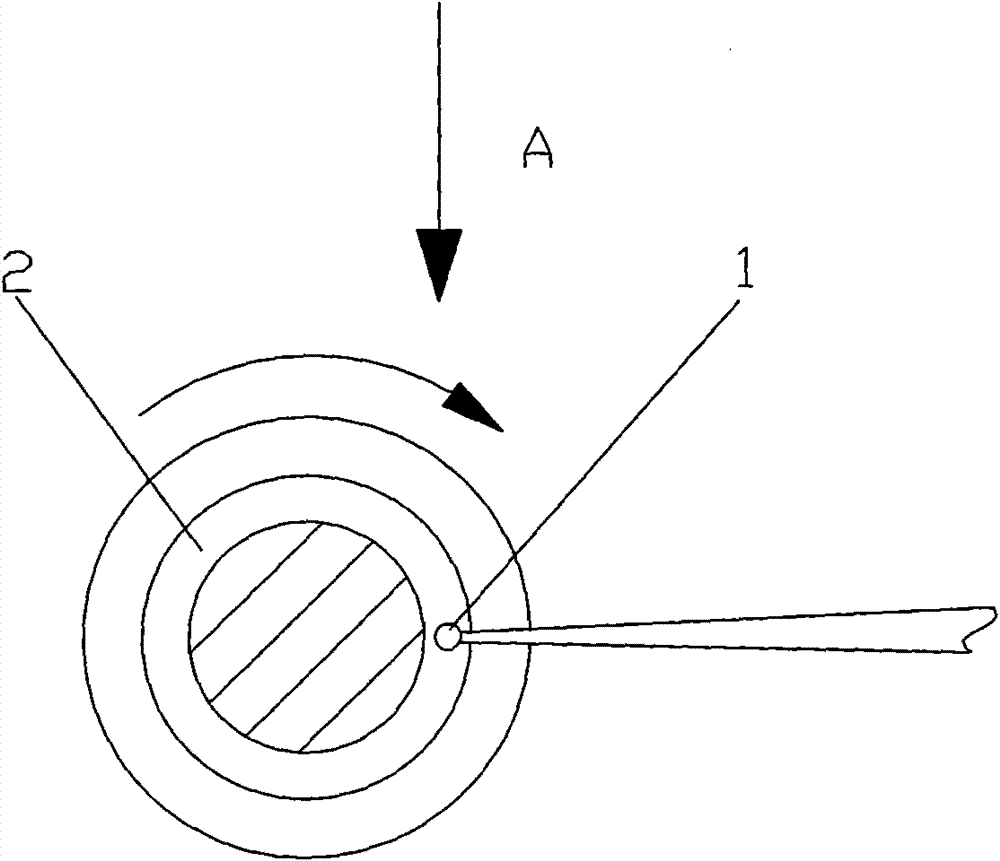

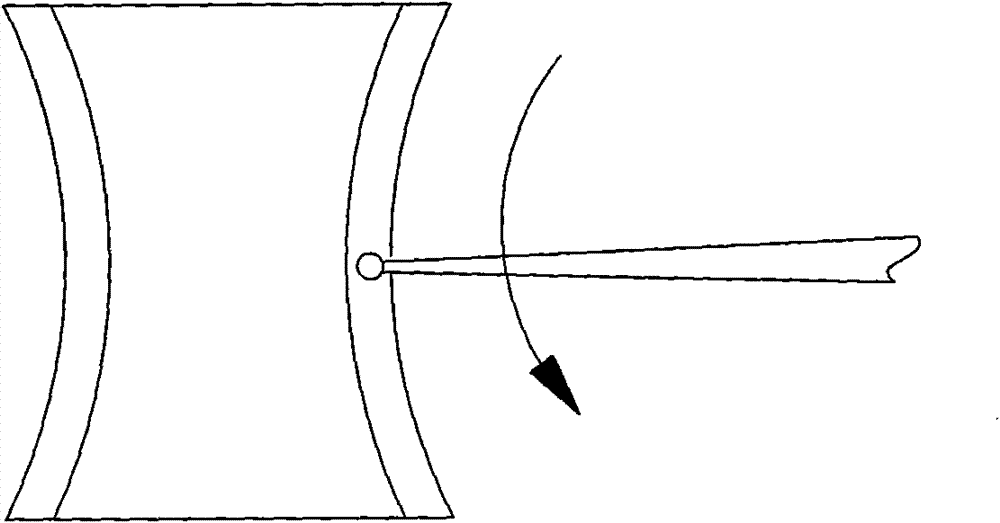

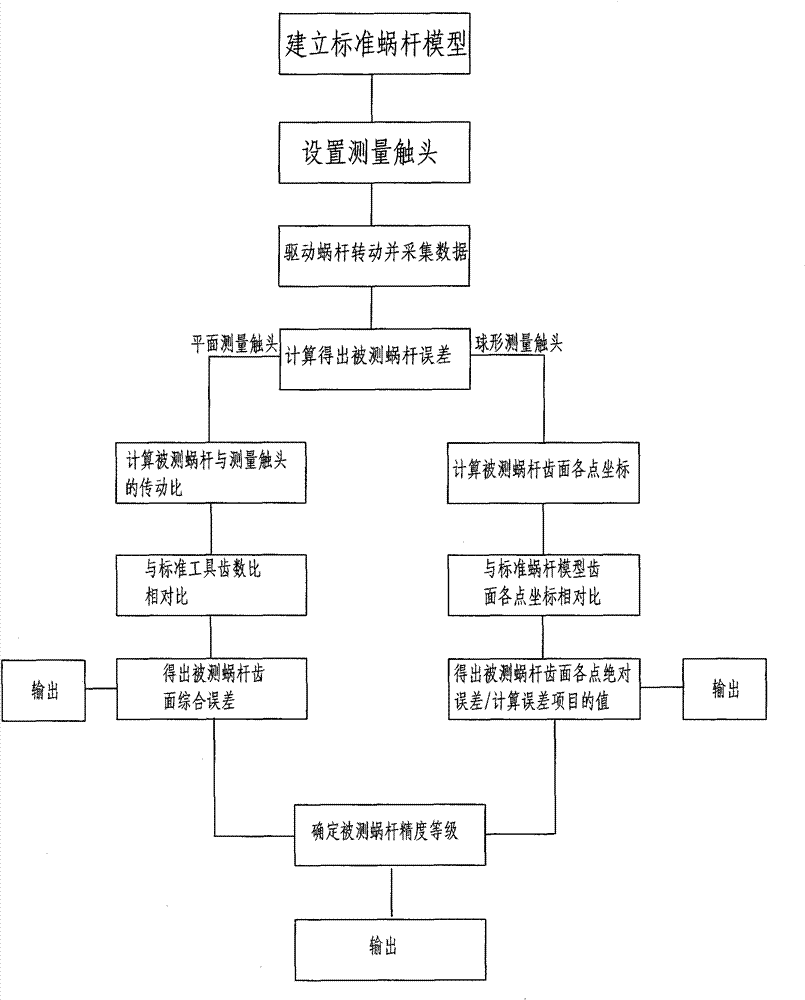

[0043] figure 1 It is a schematic diagram of cooperation between the measuring contact of the present invention and the worm to be tested, figure 2 for figure 1 View along direction A, image 3 The principle block diagram of the detection method of the present invention, as shown in the figure: the method for measuring the tooth surface error of the toroidal worm gear of the present embodiment includes the following steps:

[0044] a. Establish a theoretical worm mathematical model corresponding to the measured worm in the computer, and set a standard tool gear model;

[0045] b. Set the measuring contact 17 so that its center of rotation is consistent with the center of rotation of the standard tool gear, adjust the radius of rotation and angle of rotation of the measuring contact 17, and make the measuring contact 17 lean against the measured tooth surface of the measured worm 7 ;Standard tool gear refers to the standard gear when the theoretical worm is formed, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com