High-precision biological organic fertilizer drying machine

A bio-organic fertilizer and drying machine technology, which is applied in the direction of drying machine, drying, drying gas arrangement, etc., can solve the problems affecting the drying effect of fertilizer particles, and achieve small standard error, good drying effect and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

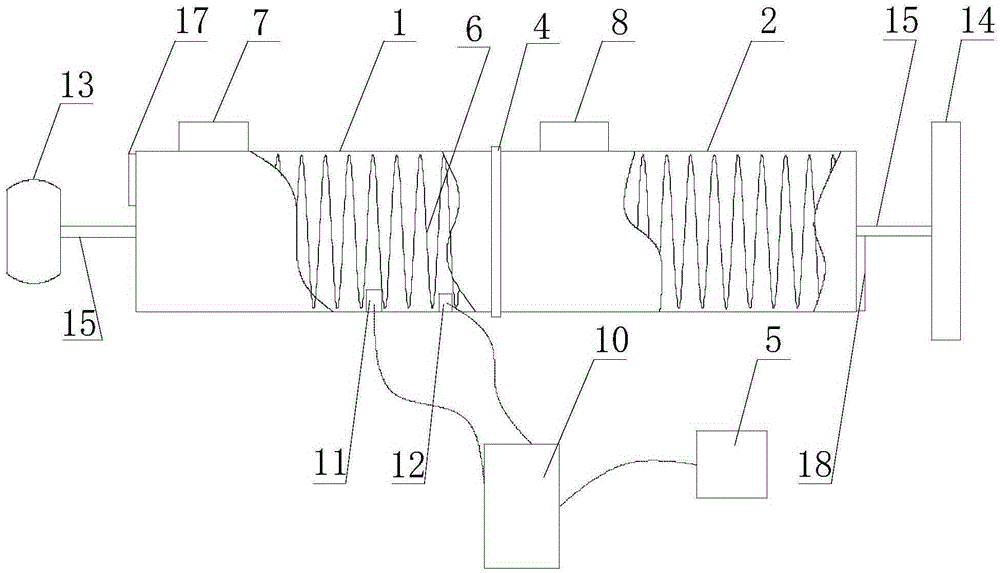

[0017] Such as figure 1 As shown, the high-precision bio-organic fertilizer dryer includes a connecting door 4, a controller 10, a temperature sensor 11 respectively arranged in the hot air cylinder 1 and the cold air cylinder 2, and a humidity sensor 11 respectively arranged in the hot air cylinder 1 and the cold air cylinder 2. The sensor 12, the hot air cylinder 1 and the cold air cylinder 2 connected in sequence; the hot air cylinder 1 and the cold air cylinder 2 are connected through the connecting door 4, and the connecting door 4 is connected with an electromagnetic switch 5 for controlling the opening and closing of the connecting door 4; the hot air cylinder 1, There are coils 6 inside the cold air cylinder 2; one end of the inner coil 6 of the hot air cylinder 1 is connected to the hot air blower 7 outside the hot air cylinder 1, and one end of the inner coil 6 of the cold air cylinder 2 is connected to the air cooler outside the cold air cylinder 2. 8 connections; t...

Embodiment 2

[0020] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the high-precision bio-organic fertilizer dryer also includes a motor 13, a fixed plate 14 and two rotating rods 15; one end of a rotating rod 15 is connected to the rotating shaft of the motor 13 , and its other end is connected with the free end of hot air cylinder 1;

[0021] Such as figure 1 Shown, when embodiment 1 and embodiment 2 are in use, the fertilizer grain of bio-organic fertilizer enters from feed inlet 17, and hot air blower 7 feeds hot blast, and hot blast flows into hot air drum 1 to dry fertilizer grain by coiled pipe 6, and hot air drum The temperature sensor 11 and the humidity sensor 12 in 1 send the temperature and humidity of the fertilizer grains to the controller 10 in real time. The connecting door 4 between them is opened, and the fertilizer particles enter the cold air cylinder 2, and the air cooler 8 sends the cold air into the cold air cylinder 2 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com