Air supply system of fuel cell with measurable humidity and humidity measuring method

An air supply and fuel cell technology, applied in fuel cells, fuel cell additives, heat measurement, etc., can solve problems such as measurement failure, easy generation of condensed water, failure of humidity sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

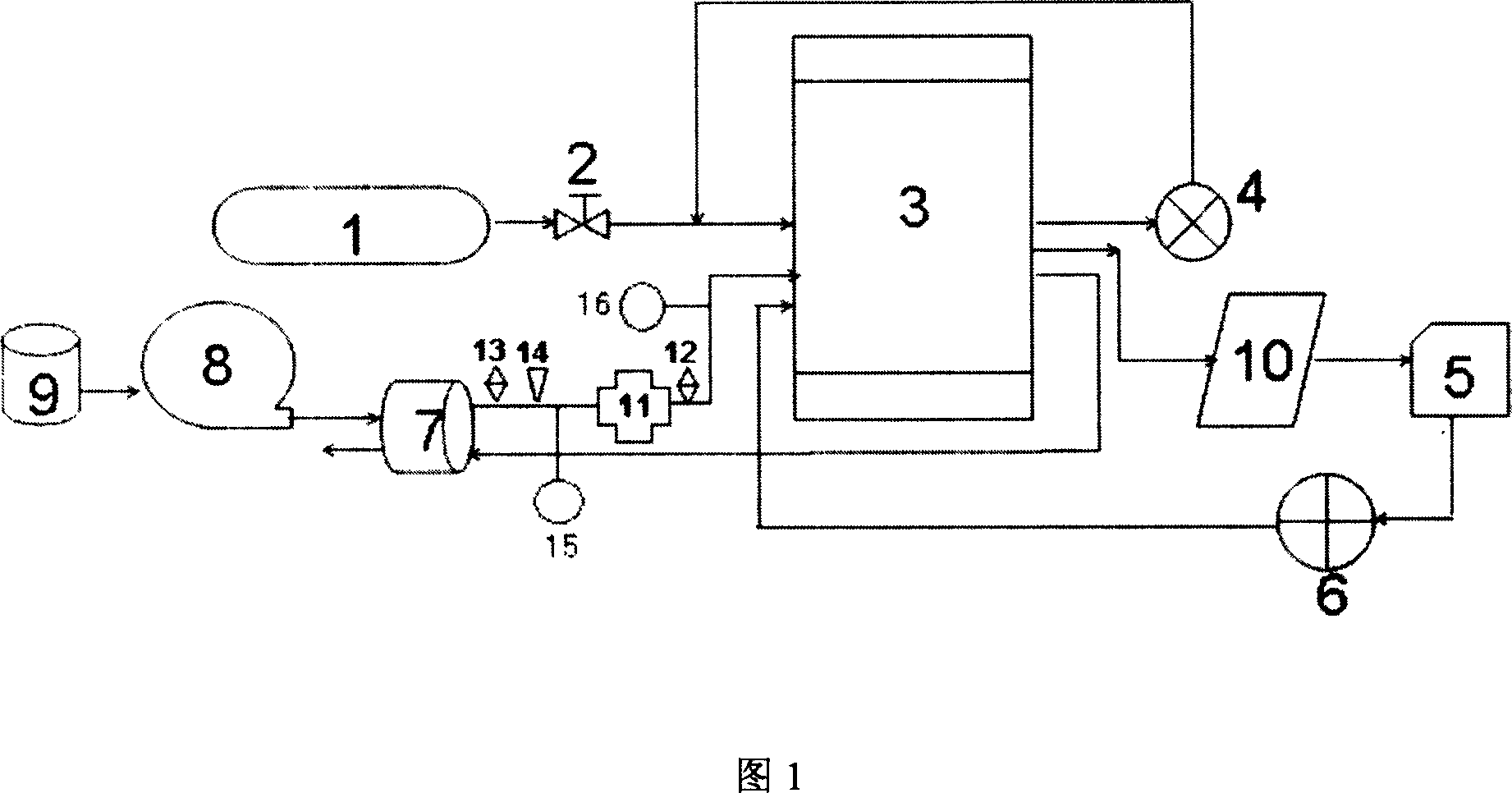

[0017] As shown in Figure 1, the hydrogen storage tank 1 of the fuel cell system stores high-pressure hydrogen gas, and the above-mentioned hydrogen gas enters the fuel cell stack 3 after passing through the pressure reducing valve 2, and a hydrogen circulation pump 4 is provided on the outlet side of the fuel cell stack 3 to return the hydrogen gas flowing out battery stack3. The air supply system of the fuel cell comprises a filter 9, a compressor 8, a humidifier 7 and an intercooler 11, the outside air is filtered through the filter 9 and enters the compressor 8, and the clean air is heated in the compressor (the temperature exceeds 130°C), and then enter the humidifier 7 to increase the humidity. Since the working temperature of the fuel cell stack 3 is below 70° C., the humidified high-temperature air also passes through the intercooler 11 to cool down, and finally enters the fuel cell stack 3 .

[0018] A humidity sensor 13, a first pressure gauge 15 and a first tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com