A rotary kiln tertiary air duct waste heat recovery device

A rotary kiln and heating device technology, applied in the field of cement processing and manufacturing, can solve problems such as damage, high-temperature corrosion and thermal strain of tertiary air pipes, and achieve the effects of inhibiting thermal strain, solving serious problems of high-temperature corrosion, and efficient heat extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

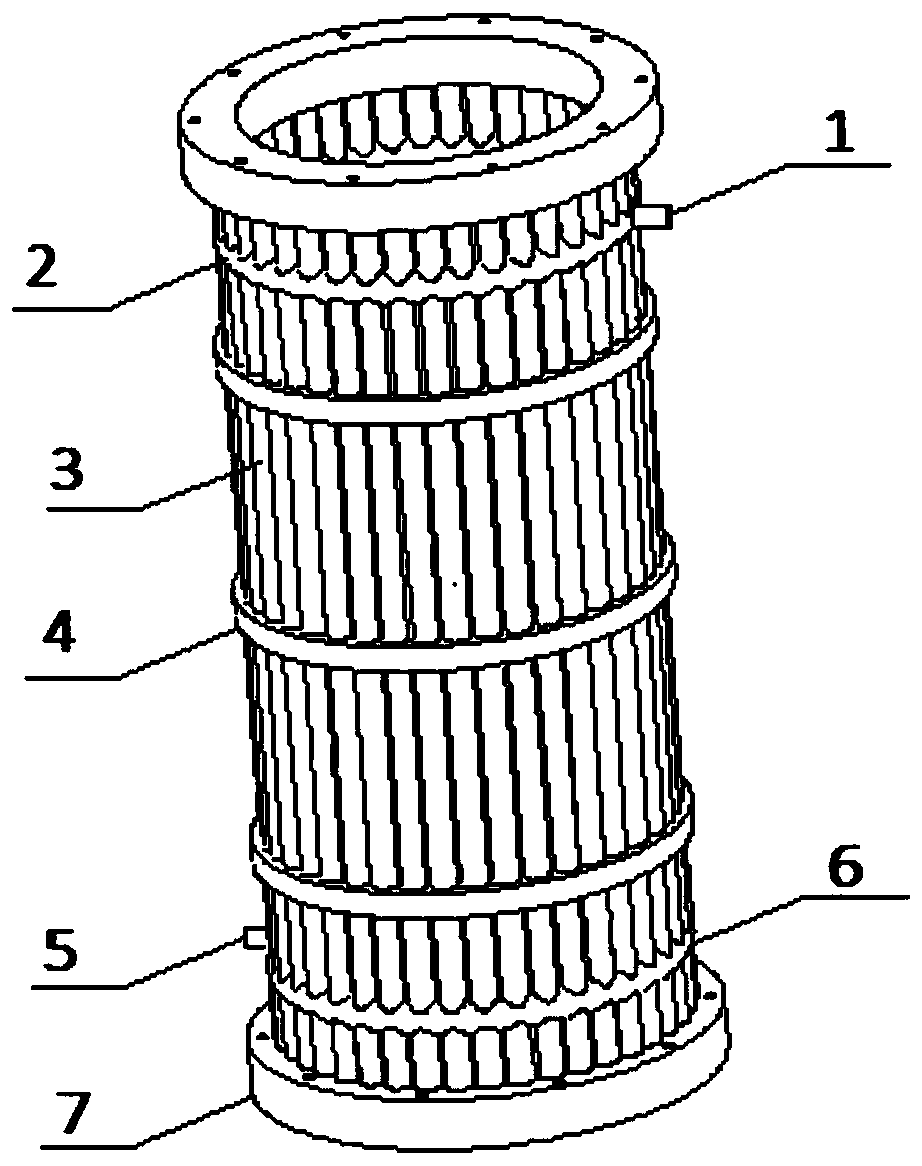

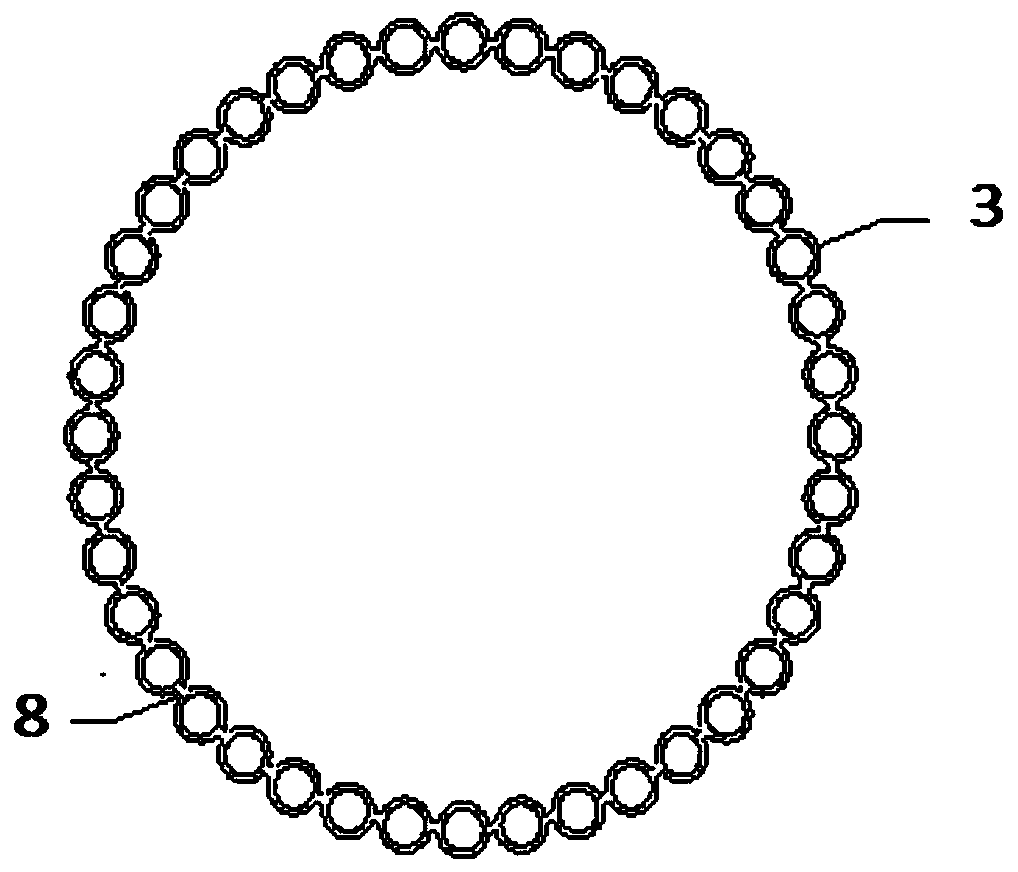

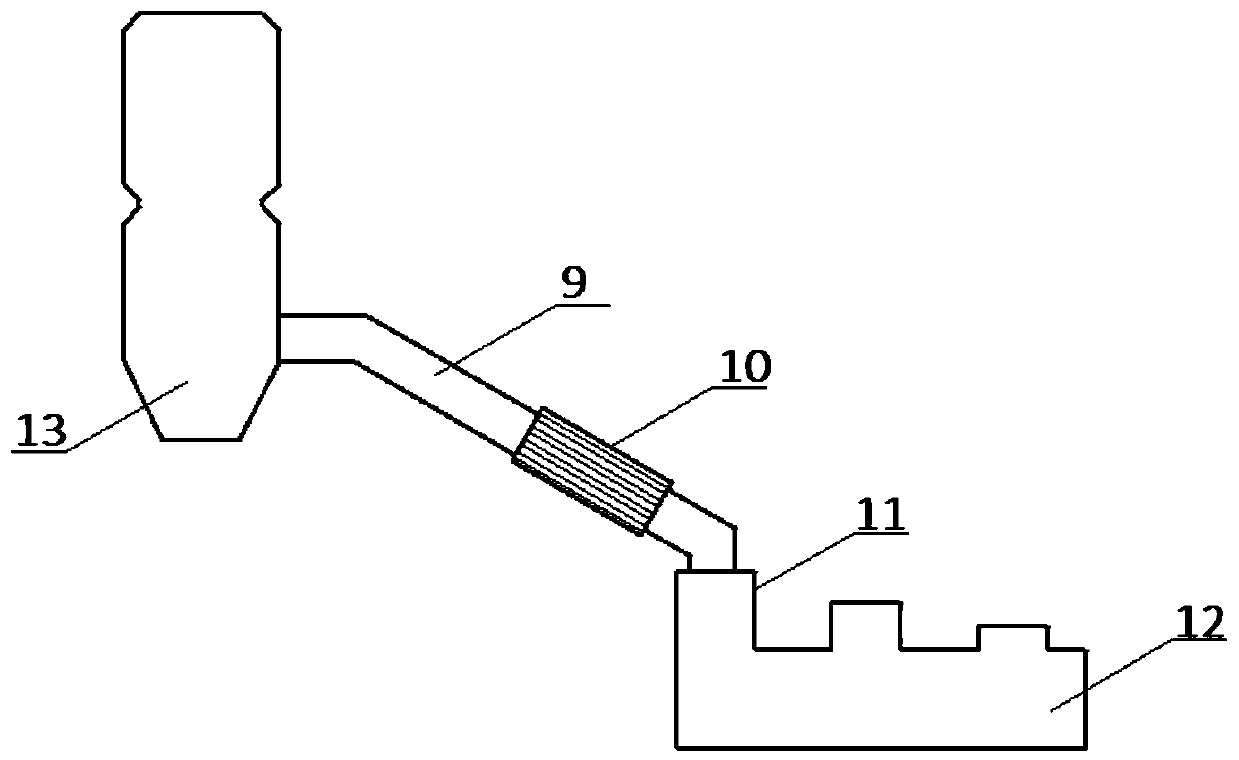

[0019] Example 1: see Figure 1 to Figure 3 , a rotary kiln tertiary air duct waste heat recovery device, comprising: heat exchange medium inlet 1, header plate 2 at the entrance, heat exchange pipe 3, fixed plate 4, heat exchange medium outlet 5, header plate 6 at the outlet, Flange 7, heat exchange pipe partition 8;

[0020] The heat exchange medium inlet 1 is used to connect to an external waste heat utilization system to connect external water flow;

[0021] The header tray 2 at the inlet is used to arrange a plurality of the heat exchange pipes 3 in a circle; the inlet 1 of the heat exchange medium is arranged on the header tray 2 at the inlet;

[0022] The heat exchange pipe 3 is used for the water flow entering the heat exchange medium inlet 1 to obtain heat in the rotary furnace through convective heat exchange and radiation scattering to form high-temperature water flow and water vapor; the inner wall of the heat exchange pipe 3 Short fins are set, and the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com