Size detection tool of automotive rear torsion beam assembly

A torsion beam and assembly technology, which is applied in the field of automotive rear torsion beam assembly specification inspection tools, can solve the problems of low detection accuracy and low efficiency of rear torsion beam assembly specifications, and improve detection accuracy and detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

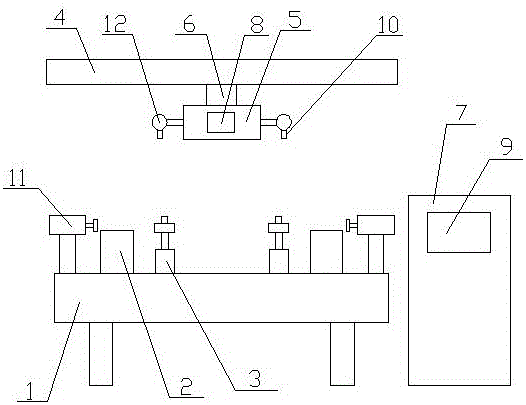

[0012] Such as figure 1 As shown, the present embodiment provides an automobile rear torsion beam assembly specification checker, including a base 1, a placing frame 2 is arranged on the base 1, and a fixing device 3 is arranged between the placing frames 2, and the A horizontal track 4 is arranged above the base 1, and an automatic scanning device 5 is arranged on the horizontal track 4, and the automatic scanning device 5 is driven by a moving device 6 to move on the horizontal track 4, and a processing electric device is arranged on the right side of the base 1. Cabinet 7, the automatic scanning device 5 is provided with a data transmission device 8, and the data scanned by the automat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap